Cancel

Bore Dia

Outer Dia

Standard Reference

Race Width

Ring Width Outer Height

Ring Width Inner Width

Mis Alignment

Ball Spherical Diameter

Race Spherical Diameter

Dynamic Radial Load

Static Radial Load

Static Thrust Load

Product Categories

/ Aerospace Bearings

Aerospace Bearings

517 ProductsAerospace bearings are a critical component in the aerospace industry, designed to meet the rigorous demands of aircraft and spacecraft applications. These bearings are essential for the reliable operation and safety of various aerospace systems.

Features of Aerospace Bearings

- High Precision and Reliability: Manufactured to exacting tolerances for consistent performance in critical aerospace applications.

- Lightweight Design: Engineered to reduce weight, which is a crucial factor in aerospace applications for fuel efficiency and performance.

- High Load Capacity: Capable of handling high dynamic and static loads typical in aircraft and spacecraft operations.

- Resistance to Harsh Environments: Designed to perform reliably in challenging conditions, including varying pressures, temperatures, and exposure to aggressive chemicals or radiation.

- Rigorous Testing and Certification: Subject to stringent testing for safety and durability, meeting the high standards of aerospace regulatory bodies.

Typical Types of Aerospace Bearings

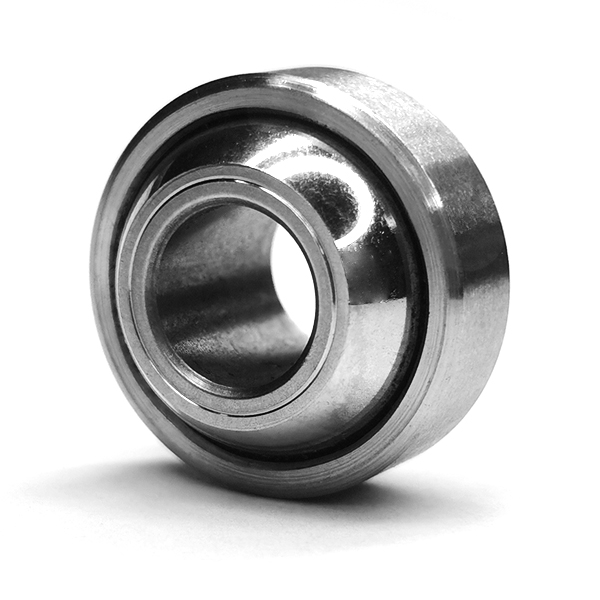

- Airframe Control Ball Bearings: Integral for aircraft control, offering high precision, corrosion resistance, and ability to manage various flight loads for safe, reliable operation.

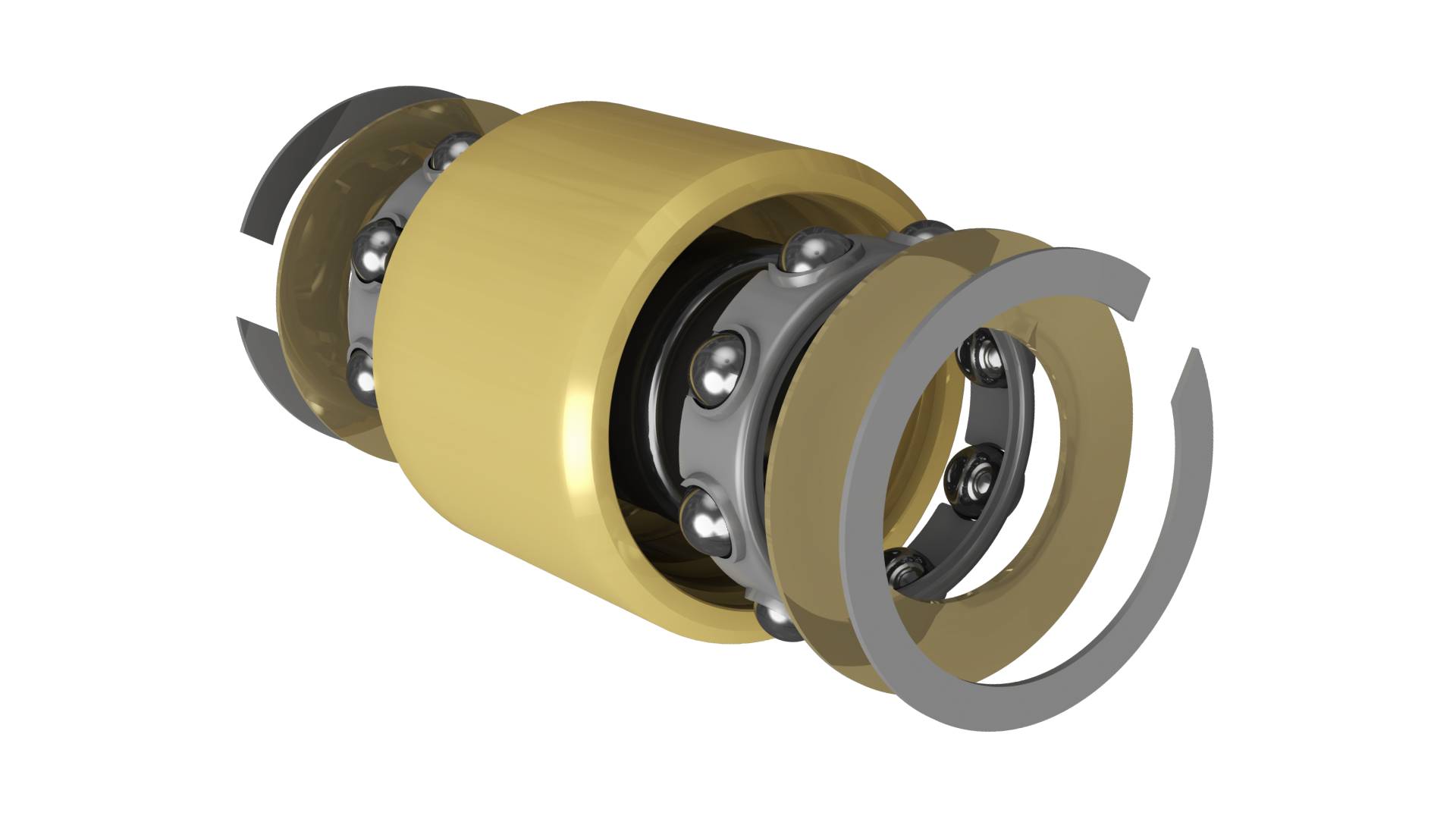

- Aerospace Spherical Bearings: Tailored for aerospace, these bearings efficiently accommodate angular misalignment, are built for extreme conditions, and offer low-maintenance, high-performance reliability.

Common Materials of Aerospace Bearings

Aerospace bearings are made from materials selected for their durability and performance in extreme conditions:

- Stainless Steel: Offers corrosion resistance and strength, suitable for harsh environments.

- Chrome Steel: High load capacity and wear resistance, ideal for high-stress applications.

- Ceramic (Silicon Nitride): Used for high-speed applications due to low friction, wear resistance, and low thermal expansion.

- Titanium Alloys: Feature a high strength-to-weight ratio and excellent high-temperature capabilities, crucial for weight-sensitive applications.

- M50 Steel: Preferred for high-temperature environments like jet engines, providing durability and resistance to thermal stress.

- Ceramic Hybrid Bearings: Combine ceramic balls with steel races, offering a mix of reduced weight, high stiffness, and thermal resistance.

Critical Applications of Aerospace Bearings

- Jet Engines: For smooth operation and handling of high temperatures.

- Landing Gear Systems: To withstand heavy loads and shocks during landing.

- Flight Control Systems: For precise maneuverability and reliability.

- Spacecraft Components: Including satellites, where durability and reliability are paramount.

Order Prompt

The order is added successfully. You can click order to pay or view