Sign in

New customer? Start here

Cancel

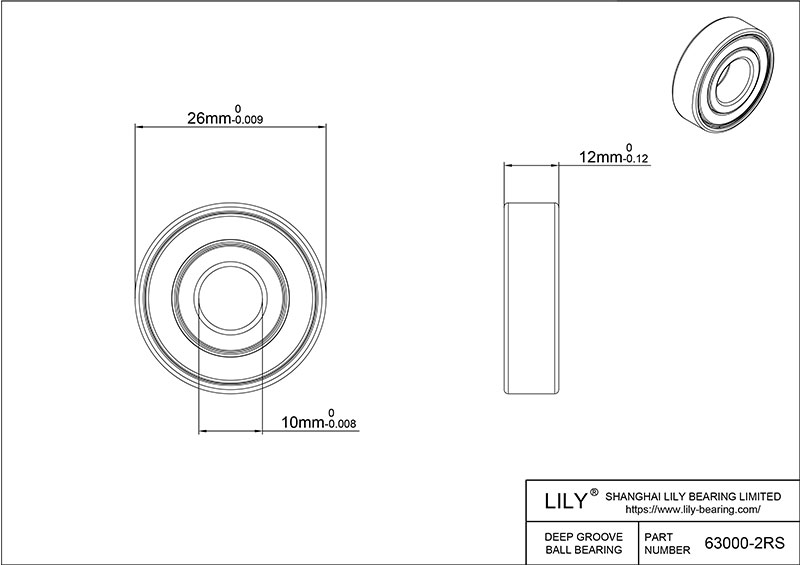

S316-63000 2rs

| Número de pieza | S316-63000 2rs |

| Sistema de medición | Métrica |

| Tipo de rodamiento | Bola |

| Para dirección de carga | Radial |

| Construcción | Fila única |

| Tipo de junta | Sellado |

| Diámetro | 10 mm |

| Tolerancia del diámetro interior | -0.008mm to 0 |

| Diámetro exterior | 26 mm |

| Tolerancia del diámetro exterior | -0.009mm to 0 |

| Anchura | 12 mm |

| Tolerancia de anchura | -0.120mm to 0 |

| Material de la virola | Acero inoxidable 316 |

| Material de la bola | Acero inoxidable 316 |

| Material del retenedor | Acero inoxidable 316 |

| Carga radial dinámica | 414 lbf |

| Carga radial estática | 180 lbf |

| Velocidad máxima (X1000 rpm) | 16.50 |

| Lubricación | Requerido |

| Tipo de montaje en eje | Ajuste a presión |

| Temperatura | -86 to 230 °F |

| Clasificación ABEC | ABEC-1 |

| Radial Clearance Trade No | C0 |

| Juego Radial | 0.003mm to 0.018mm |

| RoHS | Conforme |

| Peso | 15 g |

Design Features of S316-63000 2rs Bearing

S316-63000 2rs Bearing is a precision-engineered component designed to offer a blend of high-performance and robustness. S316-63000 2rs bore dia is 10 mm. Its out dia is 26 mm. S316-63000 2rs width is 12 mm. Crafted from AISI316L stainless steel, this bearing boasts enhanced corrosion resistance, making it well-suited for applications in challenging and damp environments.

What Benefits Can S316-63000 2rs Bearing Provide?

- High Corrosion Resistance: Especially effective against pitting and crevice corrosion in chloride environments.

- Durability: Comparable strength to other austenitic steels, but with enhanced longevity in corrosive conditions.

- Excellent Weldability and Formability: Easier to fabricate and weld without losing corrosion resistance.

- Hygienic Material: Easy to clean, making it suitable for sanitary conditions.

- Aesthetic Appeal: Maintains a clean, bright surface even in harsh conditions.

What Can S316-63000 2rs Bearing Be Used for?

S316-63000 2rs Bearing is tailored for specific applications, such as:

- Machinery: Ideal for equipment using Imperial measurement systems.

- Marine Environments: Suited for conditions with moisture and salinity due to corrosion resistance.

- Chemical Processing: Preferred in chemical industries for their resilience against corrosive substances.

- Food & Beverage Processing: Compliant with hygiene standards, reducing contamination risk.

- Medical and Pharmaceutical Equipment: Valuable for withstanding sterilization processes and resisting corrosion.

Productos recomendados