Ellex Partners with Lily Bearings to Customize High Performance Ceramic Bearings

● Oil-free dry drying allows the bearings to remain unaffected by the vacuum environment.

● Mixed ceramics reduce bearing friction, which enables ceramic bearings to operate with less friction and achieve higher speeds.

● Ceramic balls are oil-free and self-lubricating, which significantly extends bearing life by avoiding premature bearing damage caused by dried-out grease.

The Application

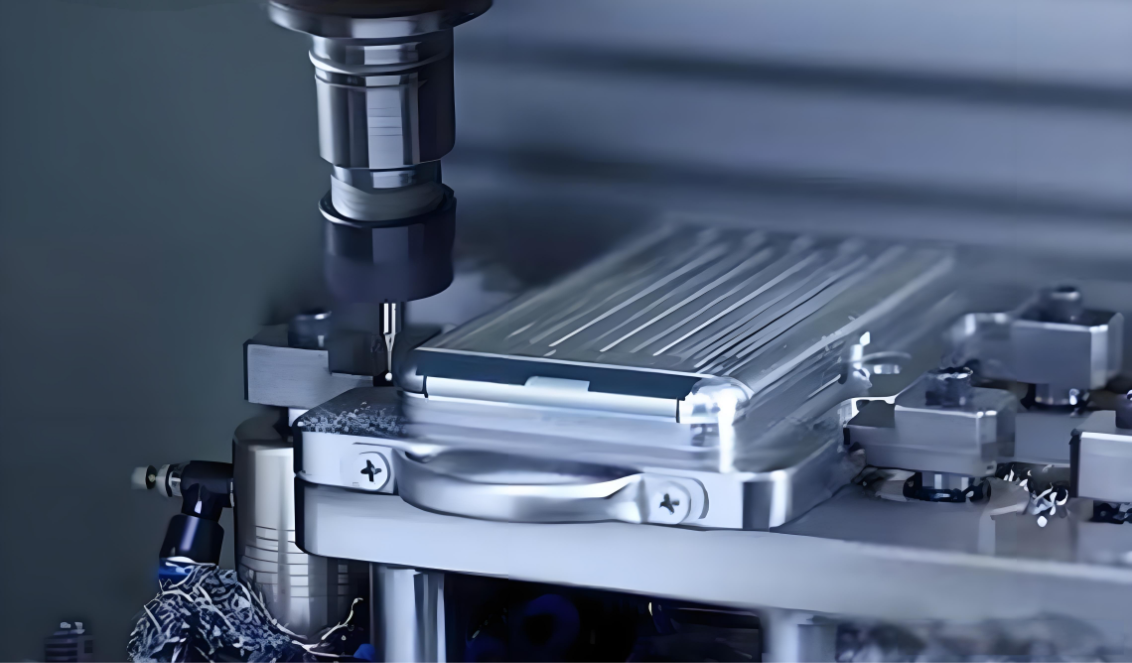

Non-standard customized hybrid ceramic miniature bearings for vacuum environment, oil-free dry baking bearings.

The Problem

The customer needed a high-speed bearing that could be used in a vacuum environment, but conventional bearings usually require periodic additions of lubricant or grease to keep them functioning properly. However, in a vacuum scenario, grease may not work effectively or even be added.

In addition, conventional bearings often have a well-defined upper speed limit. When a bearing's speed exceeds this limit, excessive heat and friction are generated, leading to increased wear and possibly even bearing damage or equipment failure.

The Solution

We provided our customer with a customized miniature bearing with hybrid ceramic oil-free dry baking, which perfectly solved all their problems.

● Lubrication issues:Hybrid oil-free dry baking ceramic bearings have oil-free self-lubricating characteristics, without adding any lubricating grease, can be in the vacuum environment for a long time stable operation.

● Bearing Damage and Longevity Issues:Ceramic bearings are not only wear-resistant, but also can avoid damage caused by grease problems, thus greatly extending the service life of bearings.

● High-speed operation requirements:The low coefficient of friction and high speed characteristics of ceramic bearings can significantly improve the operating efficiency of equipment and reduce energy consumption.

The Results

LILY Bearing collaborated closely with Ellex's engineering team to develop custom bearing solutions tailored to meet their unique operational challenges.

● Increased Service Life:Ellex's machinery saw a 30% increase in service life, allowing for extended periods of uninterrupted operation.

● Cost Control:Operational costs were reduced by 25%, thanks to the decreased need for frequent replacements and minimized risk of equipment failure.

● Faster Delivery:LILY Bearing accelerated the delivery cycle by 20%, helping Ellex maintain consistent production schedules and meet market demands without delay.

● Reduced Maintenance Costs:Maintenance costs were lowered by 40% due to the enhanced durability and self-lubricating properties of the ceramic bearings, reducing the frequency of servicing and part replacements.

“

Ellex is happy to be working with Lily Bearings for the past few years, and have always found the custom bearings supplied to be of the highest quality and excellent value.

Lily Bearings are easy to communicate with, and provide quick and friendly Customer Service. We would highly recommend Lily Bearings as a Supplier.