Polyurethane Rollers

479 ProductsPolyurethane Rollers with Bearings

Polyurethane Rollers with Screw

Polyurethane Coated Cam Followers/Track Rollers

POM Coated Bearing

What are Polyurethane Rollers?

Polyurethane rollers are a type of industrial roller used in various applications. They are made of high-performance polyurethane which is durable and abrasion-resistant, making it ideal for tough applications where traditional rubber or plastic materials would not be suitable. Polyurethane rollers offer excellent shock absorption, chemical resistance, low noise operation and long service life, making them the perfect choice for various industries.

Benefits of Using Polyurethane Rollers

The polyurethane roller can offer several advantages over other roller materials. Here are some of the key benefits:◆High level of durability: Thanks to its robust material construction, polyurethane rollers can withstand harsh environments without deteriorating or becoming damaged over time.

◆Longer life expectancy: Since they are resistant to wear and tear from abrasion, impact and chemicals, these rollers last much longer than other materials such as rubber or plastic.

◆Low rolling resistance: Due to their smooth surface finish and hard material construction, polyurethane rollers can reduce friction when operating which improves efficiency and lowers energy consumption.

◆Soundproofing: These rollers also offer excellent soundproofing properties which makes them ideal for use in noisy environments.

Advantages of Polyurethane Rollers

Compared to other materials, polyurethane rollers offer several advantages. They are highly durable and have a longer lifespan than rubber or plastic rollers. They also offer better resistance to wear and tear, chemicals, and high temperatures. Polyurethane rollers can also be customized to fit specific applications and are available in various sizes and durometers.

How to Choose Polyurethane Rollers?

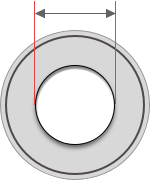

When choosing polyurethane rollers, it's important to consider factors such as load capacity, speed, and chemical resistance. The size and durometer of the roller should also be chosen based on the specific application. Other factors to consider include the roller's surface finish, bearing type, and core material.