Sign in

New customer? Start here

Cancel

210N

Price $ 16.27

Number

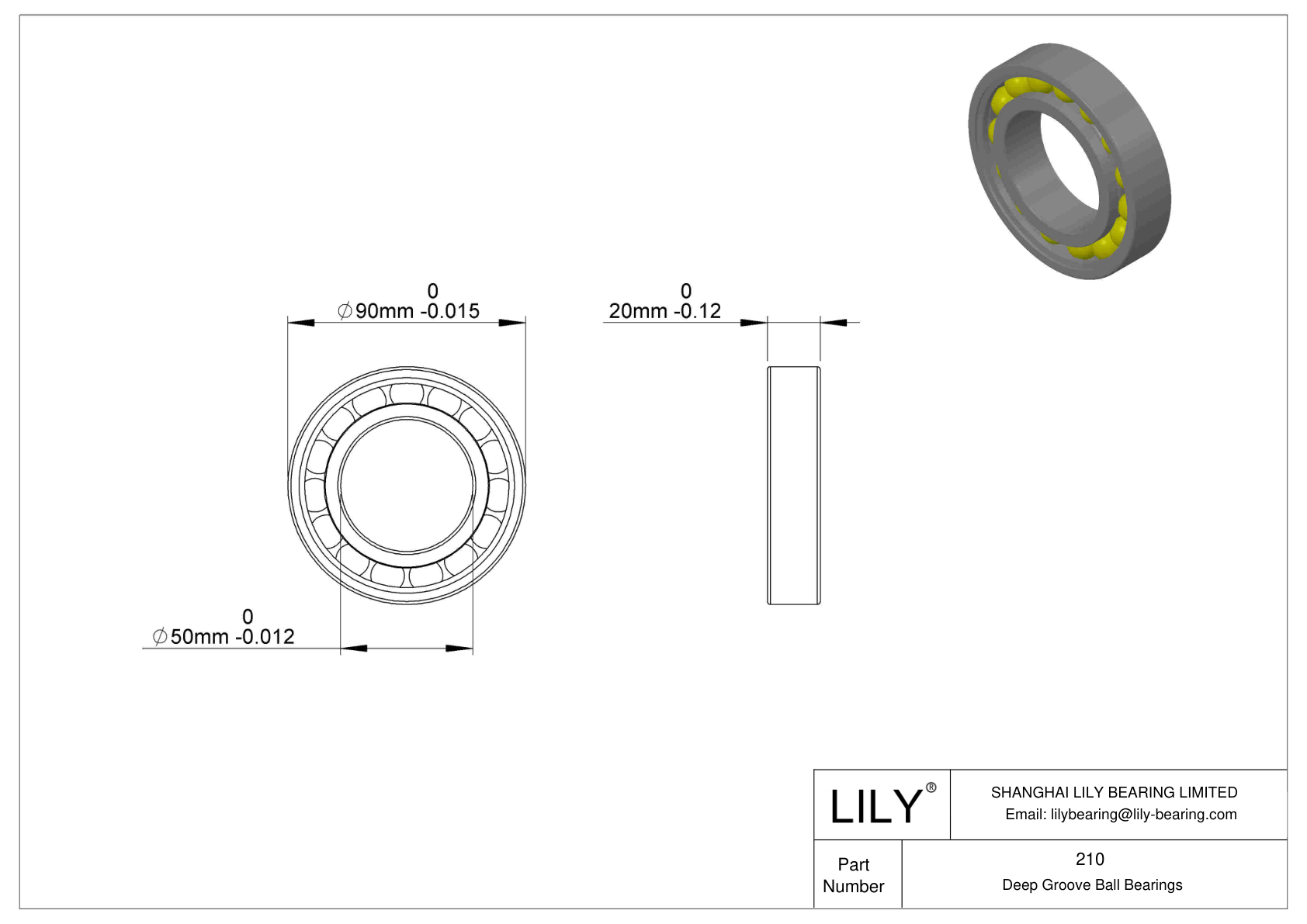

| Part Number | 210N |

Brand: LILY  |

Interchangeable With: SKF |

| System of Measurement | Metric |

| For Load Direction | Radial |

| Construction | Single Row |

| Bearing Type | Ball |

| Seal Type | Open |

| Bore Dia | 50 mm |

| Bore Dia Tolerance | -0.012mm to 0 |

| Outer Dia | 90 mm |

| Outer Dia Tolerance | -0.015mm to 0 |

| Width | 20 mm |

| Width Tolerance | -0.12mm to 0 |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Chrome Steel |

| Locating Feature Bearing Outer Ring | Snap Ring Groove |

| Dynamic Radial Load | 8790 lbf |

| Static Radial Load | 7756 lbf |

| Max Speed (X1000 rpm) | 8 |

| Lubrication | None |

| Temperature Range | -30°to 120 °C |

| ABEC Rating | ABEC 1 | ISO P0 |

| Radial Clearance Trade No | CN |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 0.5 kg |

Design Features of 210N Bearing

210N Bearing is a specialized type of rolling-element bearing that features a snap ring groove in the outer ring. 210N bore dia is 50 mm. Its out dia is 90 mm. 210N width is 20 mm. This design innovation allows for axial location of the bearing within the housing, reducing the complexity of the machine assembly and saving both time and space.

What Benefits Can 210N Bearing Provide?

- Enhanced Axial Positioning: The integrated snap ring facilitates secure axial positioning within assemblies, reducing design complexity.

- Increased Load Capacity: Inherits the high radial and moderate axial load capacities from standard deep groove ball bearings.

- Simplified Assembly: The snap ring feature simplifies installation and eliminates the need for additional location components, reducing assembly time.

- Versatility: Available in a variety of seal and shield configurations to suit different operational requirements.

- Cost-Efficiency: By integrating the snap ring feature, 210N Bearing can reduce the total number of required components, leading to cost savings in mass production.

What Can 210N Bearing Be Used for?

210N Bearing is commonly used for applications that require secure axial positioning along with radial load handling. Here are some of the common uses:

- Automotive Assemblies: Particularly in wheel hubs, transmissions, and steering mechanisms.

- Industrial Motors: Used in belt-driven setups where axial security is essential.

- Agricultural Machinery: High-load equipment such as tractors and harvesters.

- Conveyor Systems: Rollers and components requiring secure axial positioning.

- Pumps and Compressors: In settings where both high-load capacity and axial security are required.

Recommended Products