6200-2RSNR JEM

Price $ 4.07

Number

| Part Number | 6200-2RSNR JEM |

Brand: LILY  |

Interchangeable With: SKF |

| System of Measurement | Metric |

| For Load Direction | Radial |

| Construction | Single Row |

| Bearing Type | Ball |

| Seal Type | Sealed |

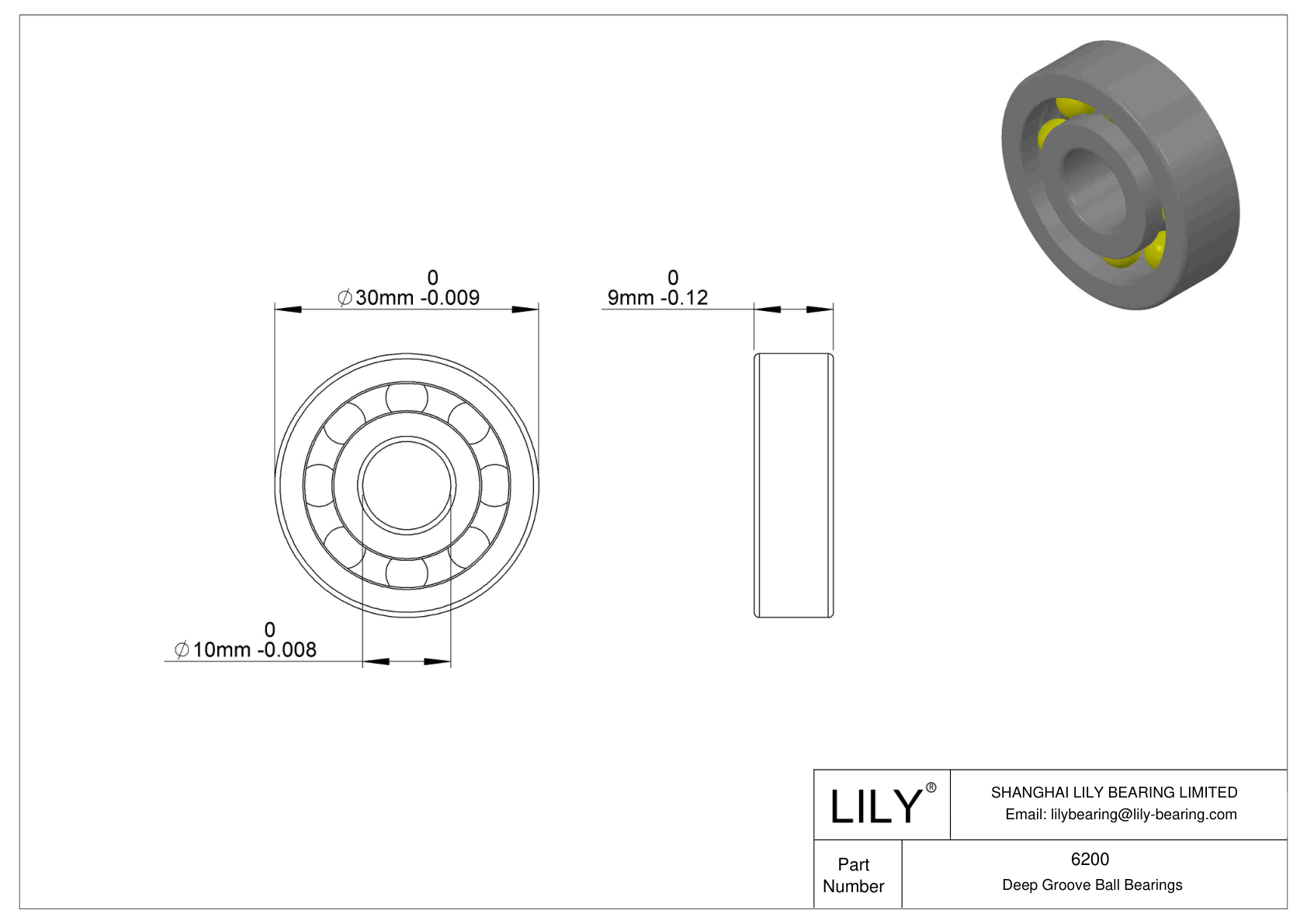

| Bore Dia | 10 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 30 mm |

| Outer Dia Tolerance | -0.009mm to 0 |

| Width | 9 mm |

| Width Tolerance | -0.120mm to 0 |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Chrome Steel |

| Locating Feature Bearing Outer Ring | Snap Ring (fitted) |

| Dynamic Radial Load | 1147 lbf |

| Static Radial Load | 54 lbf |

| Max Speed (X1000 rpm) | 24 |

| Lubrication | None |

| Temperature Range | -30°to 120 °C |

| ABEC Rating | ABEC 1 | ISO P0 |

| Radial Clearance Trade No | CN |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 32 g |

Design Features of 6200-2RSNR JEM Bearing

6200-2RSNR JEM Bearing is a specialized type of rolling-element bearing that features a snap ring groove in the outer ring. 6200-2RSNR JEM bore dia is 10 mm. Its out dia is 30 mm. 6200-2RSNR JEM width is 9 mm. This design innovation allows for axial location of the bearing within the housing, reducing the complexity of the machine assembly and saving both time and space.

What Benefits Can 6200-2RSNR JEM Bearing Provide?

- Enhanced Axial Positioning: The integrated snap ring facilitates secure axial positioning within assemblies, reducing design complexity.

- Increased Load Capacity: Inherits the high radial and moderate axial load capacities from standard deep groove ball bearings.

- Simplified Assembly: The snap ring feature simplifies installation and eliminates the need for additional location components, reducing assembly time.

- Versatility: Available in a variety of seal and shield configurations to suit different operational requirements.

- Cost-Efficiency: By integrating the snap ring feature, 6200-2RSNR JEM Bearing can reduce the total number of required components, leading to cost savings in mass production.

What Can 6200-2RSNR JEM Bearing Be Used for?

6200-2RSNR JEM Bearing is commonly used for applications that require secure axial positioning along with radial load handling. Here are some of the common uses:

- Automotive Assemblies: Particularly in wheel hubs, transmissions, and steering mechanisms.

- Industrial Motors: Used in belt-driven setups where axial security is essential.

- Agricultural Machinery: High-load equipment such as tractors and harvesters.

- Conveyor Systems: Rollers and components requiring secure axial positioning.

- Pumps and Compressors: In settings where both high-load capacity and axial security are required.

Recommended Products