Sign in

New customer? Start here

Cancel

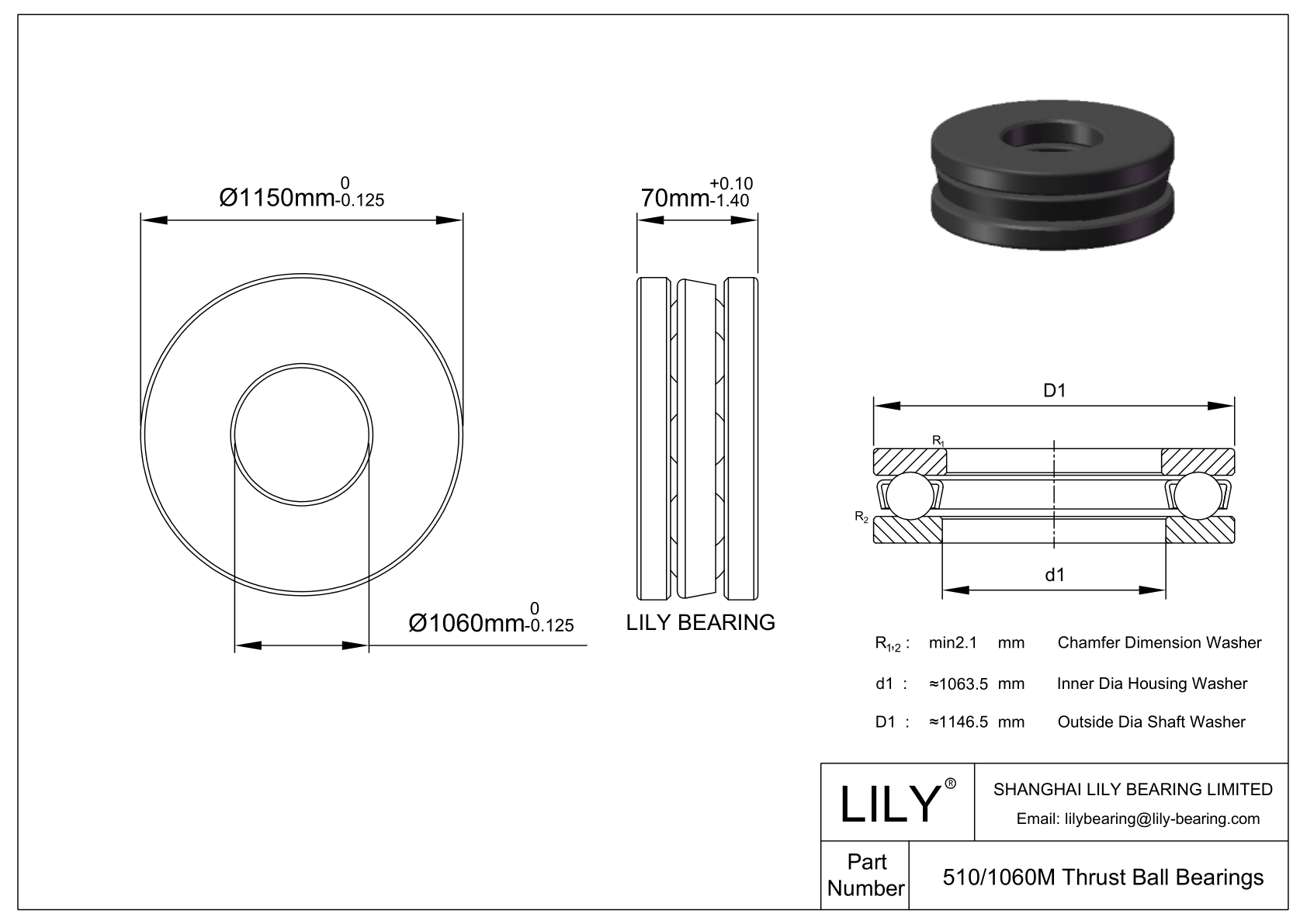

CE510/1060 MSC

| Part Number | CE510/1060 MSC |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Thrust |

| Construction | Single Direction |

| Bore Dia | 1060 mm |

| Bore Dia Tolerance | -0.125mm to 0 |

| Outer Dia | 1150 mm |

| Outer Dia Tolerance | -0.125mm to 0 |

| Outer Dia Shaft Washer | 1146.5 mm |

| Width | 70 mm |

| Width Tolerance | +0.1mm to -1.4mm |

| Chamfer Dimension Washer | 2.1 mm |

| Inner Dia Housing Washer | 1063.5 mm |

| Ring Material | Silicon Carbide |

| Balls Material | Sic |

| Cage Material | PEEK |

| Dynamic Axial Load | 25718 lbf |

| Static Axial Load | 263026 lbf |

| Max Speed (X1000 rpm) | 0.42 |

| Temperature Range | -176 to 2192 °F |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 29 kg |

Design Features of CE510/1060 MSC Bearing

CE510/1060 MSC Bearing is a specialized type of bearing designed to provide superior performance in challenging environments, using the advanced properties of Silicon Carbide (SiC). CE510/1060 MSC bore dia is 1060 mm. Its out dia is 1150 mm. CE510/1060 MSC height is Height. This bearing offers a combination of hardness, thermal stability, chemical resistance, and versatility that is unmatched by traditional bearing materials.

What Benefits Can CE510/1060 MSC Bearing Provide?

- Exceptional Wear Resistance: Its extreme hardness ensures outstanding durability and longevity, even in abrasive conditions.

- High Thermal Stability: Excellent performance at high temperatures, maintaining integrity and functionality in thermal extremes.

- Chemical and Corrosion Resistance: Resistant to a wide array of chemicals, making this bearing suitable for harsh industrial environments.

- High-Speed Capability: Its design ensures stable, efficient performance at high speeds, ideal for precision machinery and high-speed applications.

- High Load Capacity: Its robustness enables this bearing to handle high load capacities, essential in heavy-duty industrial applications.

What Can CE510/1060 MSC Bearing Be Used for?

CE510/1060 MSC Bearing is suited for a variety of professional and industrial applications, such as:

- Industrial Machinery: In high-speed machinery and equipment, such as turbines and compressors, due to its high-speed capability and thermal stability.

- Semiconductor Manufacturing: Where precision and resistance to harsh chemicals are necessary, making this bearing suitable for fabrication equipment.

- Energy Sector: In applications like power generation equipment, where durability under high temperature and corrosive conditions is essential.

- Aerospace Industry: For components in aircraft and spacecraft, where high strength, low weight, and thermal stability are critical.

Recommended Products