Sign in

New customer? Start here

Cancel

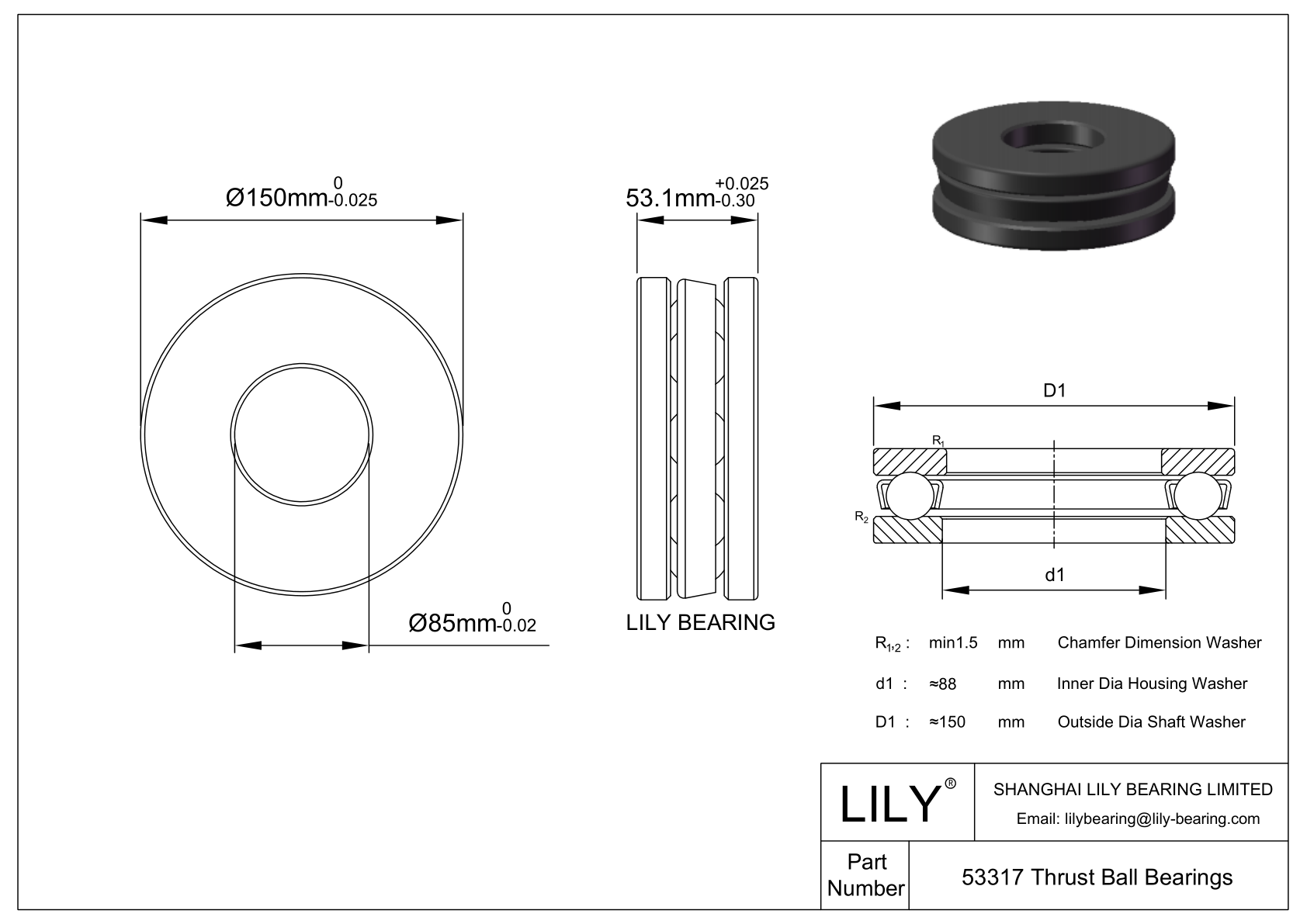

CE53317SI

| Part Number | CE53317SI |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Thrust |

| Construction | Single Direction |

| Bore Dia | 85 mm |

| Bore Dia Tolerance | -0.02mm to 0 |

| Outer Dia | 150 mm |

| Outer Dia Tolerance | -0.025mm to 0 |

| Outer Dia Shaft Washer | 150 mm |

| Width | 53.1 mm |

| Width Tolerance | +0.025mm to -0.3mm |

| Chamfer Dimension Washer | 1.5 mm |

| Inner Dia Housing Washer | 88 mm |

| Ring Material | Silicon Nitride |

| Balls Material | Si3n4 |

| Cage Material | PEEK |

| Dynamic Axial Load | 9779 lbf |

| Static Axial Load | 22762 lbf |

| Max Speed (X1000 rpm) | 1.4 |

| Temperature Range | -176 to 1472 °F |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 3.262 kg |

Design Features of CE53317SI Bearing

Crafted from Silicon Nitride (Si3N4), a high-strength, hard ceramic material, CE53317SI Bearing is engineered for superior performance in demanding environments. CE53317SI bore dia is 85 mm. Its out dia is 150 mm. CE53317SI height is Height. This bearing is a preferred choice for cutting-edge industrial and technological applications.

What Benefits Can CE53317SI Bearing Provide?

- Exceptional Durability: Its high mechanical strength and wear resistance ensure long-lasting performance under demanding conditions.

- Thermal Stability: Excellent performance in extreme temperatures, crucial for applications in aerospace and automotive industries.

- High-Speed Capability: Suitable for high-speed applications due to lower centrifugal forces and enhanced stability at high rotations.

- Corrosion Resistance: Resilient in corrosive environments, making this bearing ideal for chemical processing and other harsh industrial applications.

- Electrical Insulation: Its non-conductive nature prevents electrical currents from passing through, crucial in electric motors and electronic equipment to avoid electrical damage.

What Can CE53317SI Bearing Be Used for?

CE53317SI Bearing is suited for a variety of professional and industrial applications, such as:

- Aerospace Industry: Utilized in aircraft and spacecraft systems for their lightweight and ability to withstand extreme temperatures and speeds.

- Automotive Engineering: Ideal for high-performance and electric vehicles, where high-speed capability and thermal stability are essential.

- Chemical Processing: Their corrosion resistance makes them suitable for pumps, valves, and other machinery exposed to corrosive substances.

- High-Speed Machinery: Used in high-speed CNC machines, spindles, and turbines where stability at high rotational speeds is critical.

- Medical Equipment: Their biocompatibility and stability under sterilization conditions make them suitable for high-precision medical devices.

Recommended Products