CGIFTBI

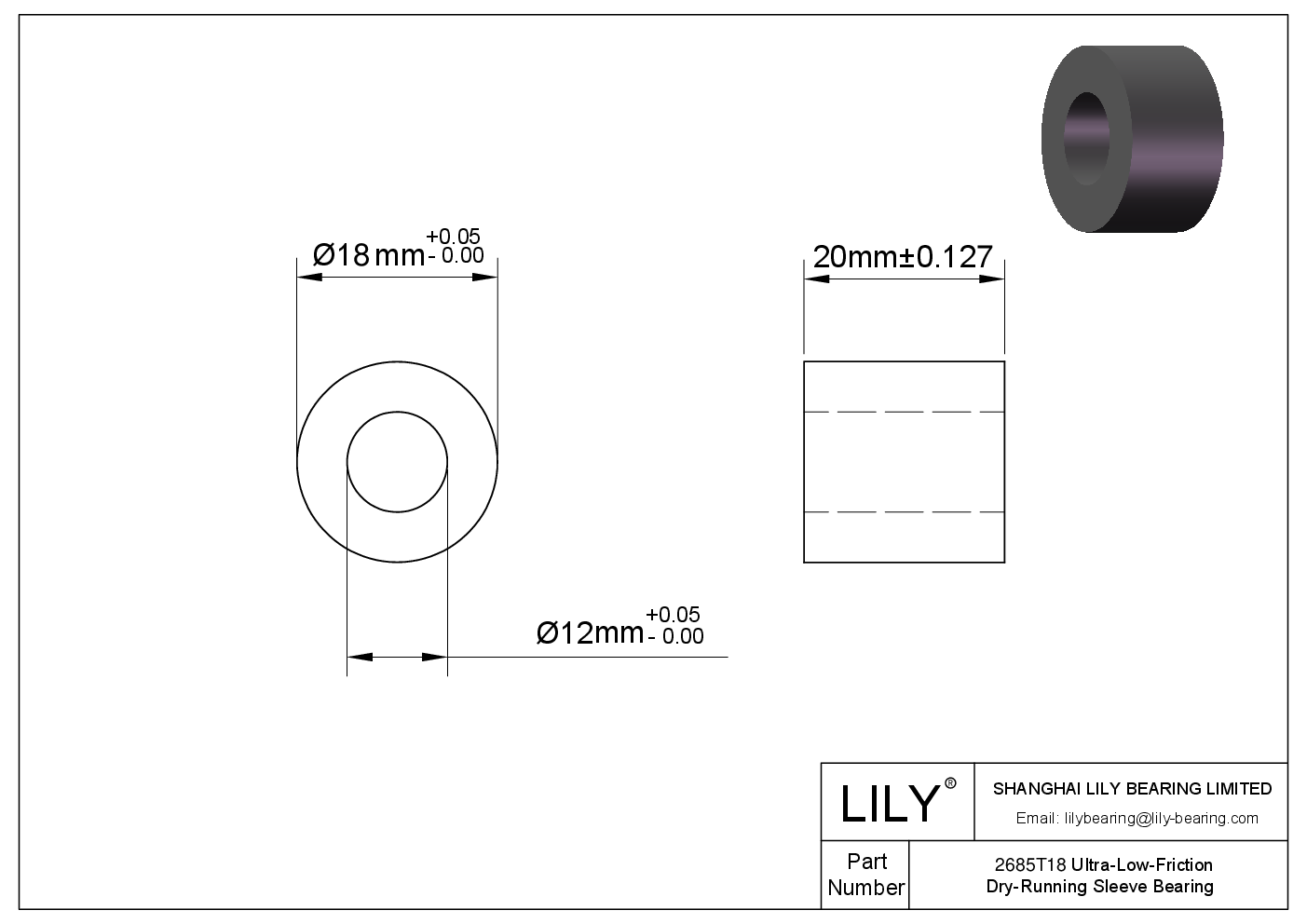

| Part Number | CGIFTBI |

| System of Measurement | Metric |

| Bearing Type | Plain |

| Plain Bearing Type | Sleeve |

| For Load Direction | Radial |

| For Shaft Diameter | 12 mm |

| Bore Dia | 12 mm |

| Bore Dia Tolerance | 0 mm to 0.05 mm |

| For Housing ID | 18mm |

| Outer Dia | 18 mm |

| Outer Dia Tolerance | 0 to 0.05 mm |

| Length | 20 mm |

| Length Tolerance | -0.127mm to 0.127mm |

| Dynamic Radial Load | 25 lbf |

| Static Radial Load | 25 lbf |

| Max Speed (X1000 rpm) | 0.12 |

| Material | PTFE Plastic |

| Lubrication | Not Required |

| For Shaft Type | Round |

| Shaft Mount Type | Slip Fit |

| Temperature Range | -350° to 500° F |

| RoHS | Compliant |

| REACH | Compliant |

INTERCHANGE

The LILY Bearing part series CGIFTBI is a potential replacement for these common bearing part numbers.

LILY

MCMASTER

CGIFTBI

2685T18

Design Features of CGIFTBI Bearing

CGIFTBI Bearing consists of composite or engineered plastic material with self-lubricating additives. It has precise inner and outer diameters, wear-resistant surfaces, and strong reinforcement fibers. CGIFTBI bore dia is 12 mm. Its outer dia is 18 mm. CGIFTBI length is 20 mm. The bearing provides reliable performance and enhanced durability for industrial applications.

What Benefits Can CGIFTBI Bearing Provide?

- Low Friction Coefficient: It helps cut down on energy loss, which in turn increases the efficiency and performance of the machinery.

- Dry-Running Capability:It does not require any lubricants. This reduces the need for maintenance and has a positive impact on the environment.

- Wear Resistance: The bearing lasts longer and performs well in tough conditions.

- Chemical Resistance: It works well with chemicals and withstands corrosion.

- Lightweight: Makes machinery lighter, which is helpful in many applications.

What Can CGIFTBI Bearing Be Used for?

- Food and Beverage Industry: The bearing is perfect for machinery where the use of lubricants is not possible. This ensures smooth operation without the risk of contamination.

- Automotive: It can be employed in components where lubrication is difficult or impossible.

- Medical Devices: The bearing ensures clean and maintenance-free operation.

- Aerospace: It is suitable for applications requiring reliability and low maintenance.