CIGHTBCB

| Part Number | CIGHTBCB |

| System of Measurement | Metric |

| Bearing Type | Plain |

| Plain Bearing Type | Sleeve |

| For Load Direction | Radial |

| For Shaft Diameter | 10 mm |

| Bore Dia | 10 mm |

| Bore Dia Tolerance | -0.03 mm to 0.03 mm |

| For Housing ID | 12 mm |

| Outer Dia | 12 mm |

| Outer Dia Tolerance | -0.05 mm to 0.08 mm |

| Length | 20 mm |

| Length Tolerance | -0.13mm to 0.13mm |

| Dynamic Radial Load | 3100 lbf |

| Static Radial Load | 3100 lbf |

| Max Speed (X1000 rpm) | 0.12 |

| Material | 954 Aluminum-Bronze |

| Lubrication | Required |

| For Shaft Type | Round |

| Shaft Mount Type | Slip Fit |

| Temperature Range | -350° to 500° F |

| RoHS | Compliant |

| REACH | Compliant |

INTERCHANGE

The LILY Bearing part series CIGHTBCB is a potential replacement for these common bearing part numbers.

LILY

MCMASTER

CIGHTBCB

2867T121

Design Features of CIGHTBCB Bearing

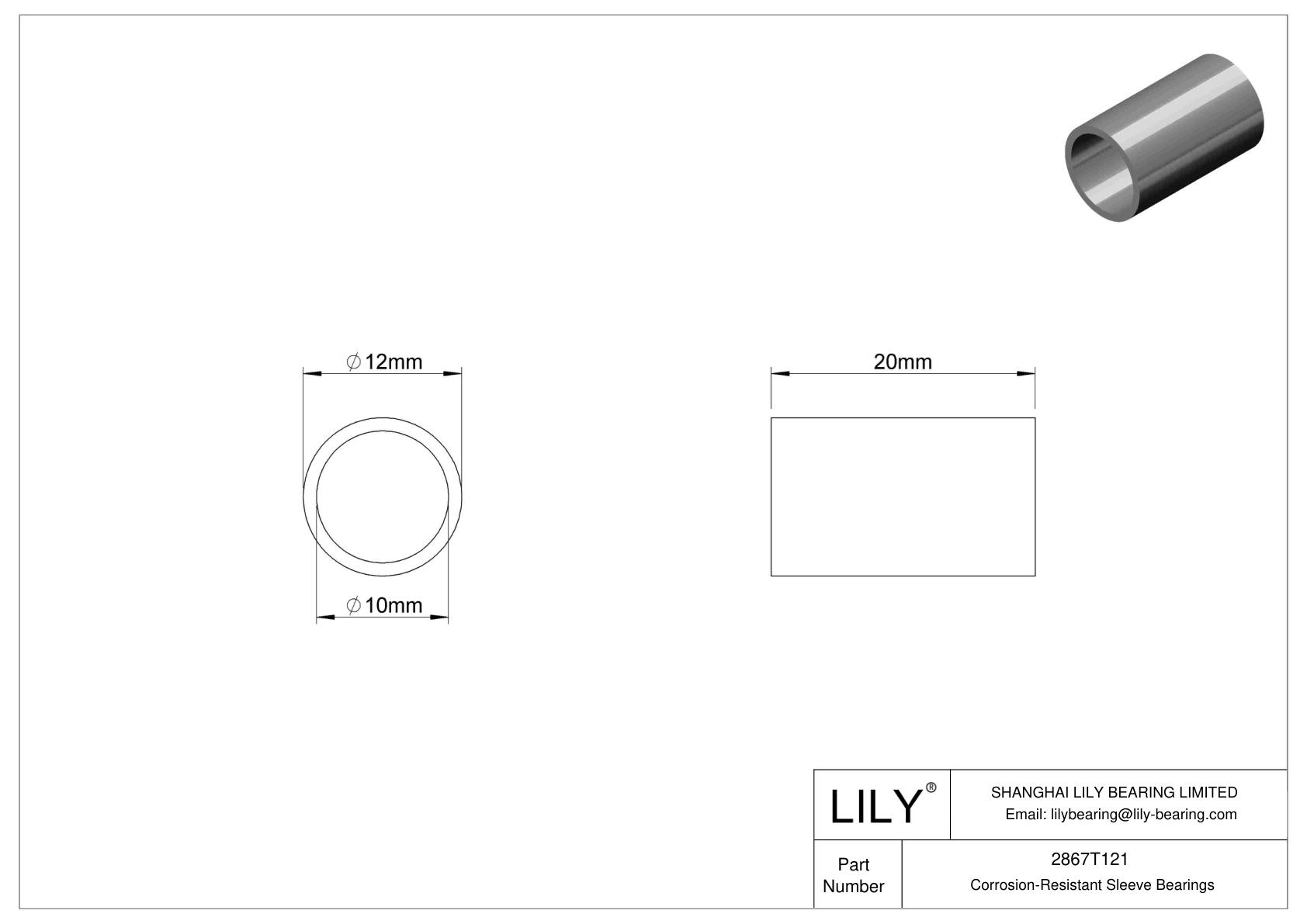

CIGHTBCB Bearing has an inner diameter that fits snugly around the shaft for smooth operation. The outer diameter fits securely into the housing for stability. The length determines the bearing's load capacity and wear distribution. CIGHTBCB bore dia is 10 mm. Its outer dia is 12 mm. CIGHTBCB length is 20 mm. The bearing is essential for applications requiring reliability and longevity. It performs well even in tough conditions.

What Benefits Can CIGHTBCB Bearing Provide?

- Durability: The bearing is made from materials chosen for their resistance to corrosion, so it lasts longer in harsh environments.

- Low Maintenance: It is often self-lubricating. This reduces the need for regular maintenance and lubrication.

- Versatility: It is suitable for a wide range of applications. This is due to the variety of corrosion-resistant materials and designs available.

- Reliability: The bearing works reliably and reduces downtime in corrosive environments. This enhances overall equipment reliability.

What Can CIGHTBCB Bearing Be Used for?

- Marine: This bearing is used in ship propellers and underwater equipment. It’s ideal for maritime applications where saltwater causes rapid corrosion.

- Chemical Processing: It is ideal for pumps, valves, and other equipment. These are often exposed to harsh chemicals.

- Food and Beverage: It is suitable for machinery in food processing plants. These machines are regularly cleaned and exposed to water and cleaning agents.

- Medical Equipment: This bearing is used in devices and machinery. It must withstand sterilization and exposure to bodily fluids.