F4-9M

Price $ 1.55

Number

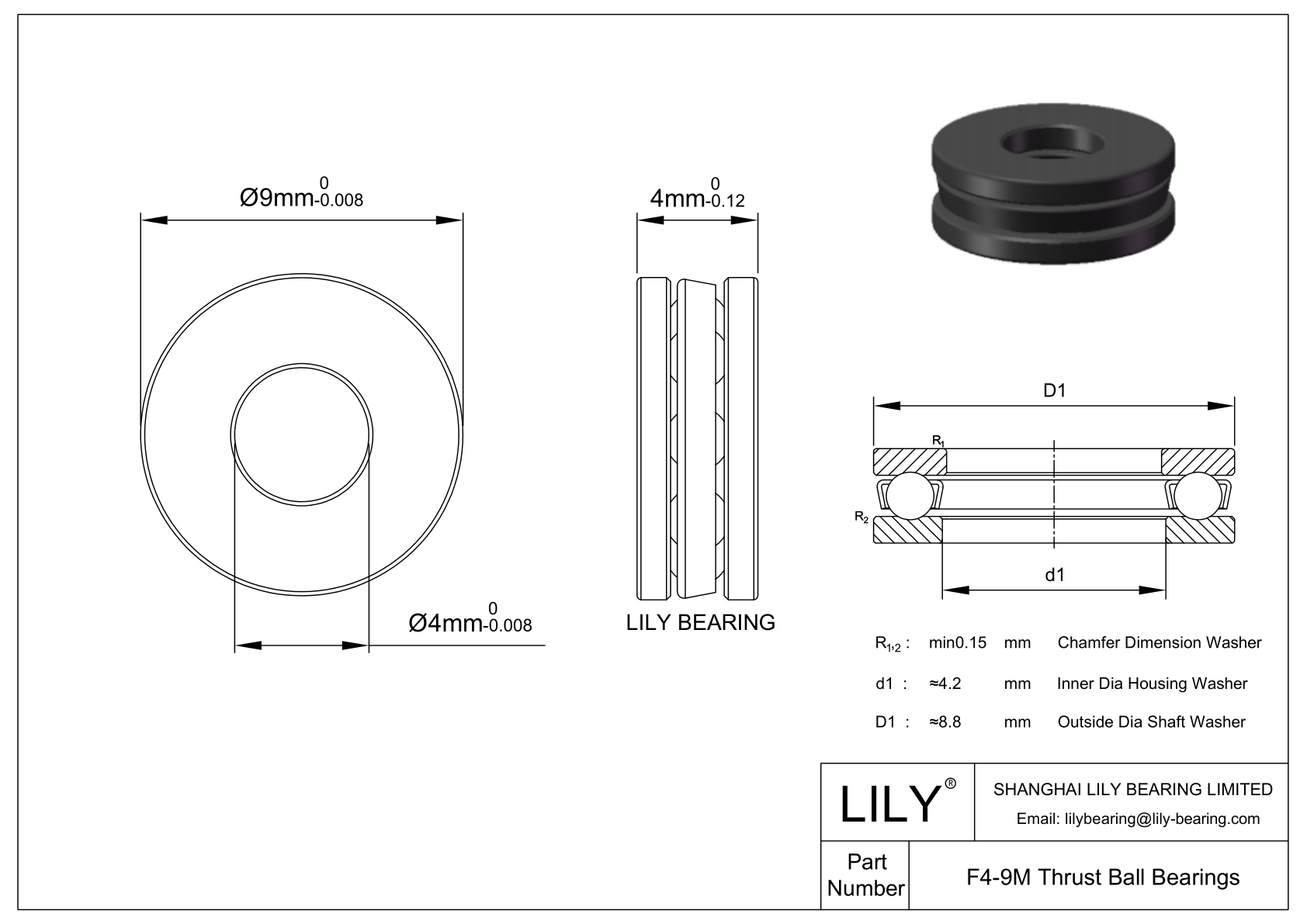

| Part Number | F4-9M |

Brand: LILY  |

Interchangeable With: SKF |

| System of Measurement | Metric |

| Bearing Type | Ball |

| Washers Type | grooved raceway |

| For Load Direction | Thrust |

| Inner Ring Type | Standard |

| Seal Type | Open |

| Bore Dia | 4 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 9 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Housing Washer ID | 4.2 mm |

| Shaft Washer OD | 8.8 mm |

| Width | 4 mm |

| Width Tolerance | -0.12mm to 0 |

| Washer Material | 52100 Chrome Steel |

| Ball Material | 52100 Chrome Steel |

| Cage Material | Brass |

| Dynamic Thrust Load | 180 lbf |

| Static Thrust Load | 117 lbf |

| Max Speed (X1000 rpm) | 8 |

| Lubrication | Required |

| Temperature Range | -30° to 110 °C |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 1.588 mm |

| Ball Qty | 6 |

| Weight | 1.2 g |

INTERCHANGE

The LILY Bearing part series F4-9M is a potential replacement for these common bearing part numbers.

LILY

DYNAROLL

MCMASTER

LF4-9M

F4-9M

7806K54

Design Features of F4-9M Bearing

F4-9M Bearing is a type of rolling-element bearing designed explicitly to handle axial loads in one direction. F4-9M bore dia is 4 mm. Its out dia is 9 mm. F4-9M height is Height. This bearing comprises a shaft washer affixed to the rotating shaft, paired with a stationary housing washer. Spherical balls, positioned between these washers, mitigate friction and facilitate smooth rotation. A dedicated cage maintains uniform spacing among the balls, preventing contact and assisting in lubricant distribution.

What Benefits Can F4-9M Bearing Provide?

- Axial Load Handling: This bearing is made to manage one-way axial loads efficiently.

- Space-saving: Its design is compact, ideal for tight spaces.

- Smooth Operation: Balls reduce friction, ensuring smoother rotation.

- Speed: Due to its precision crafting, this bearing is suited for high-speed applications.

- Alignment Flexibility: Variants with grooved aligning seat washers can accommodate minor shaft misalignments, enhancing operational reliability.

What Can F4-9M Bearing Be Used for?

F4-9M Bearing is integral in a wide array of applications owing to their ability to manage axial loads efficiently. Here are some common applications:

- Industrial Machinery: Often used in high-speed radial drilling machines.

- Automotive Sector: Applied in systems like clutches for efficient axial load management.

- Aerospace Industry: Incorporated in various components for reliable high-speed operations.

- Home Appliances: Used in devices like washing machines to reduce friction.

- Precision Instruments: Essential in printer peripherals for accurate axial load control.