GDHHKFBF

| Part Number | GDHHKFBF |

| System of Measurement | Metric |

| Bearing Type | Plain |

| Plain Bearing Type | Sleeve |

| For Load Direction | Radial |

| For Shaft Diameter | 7mm |

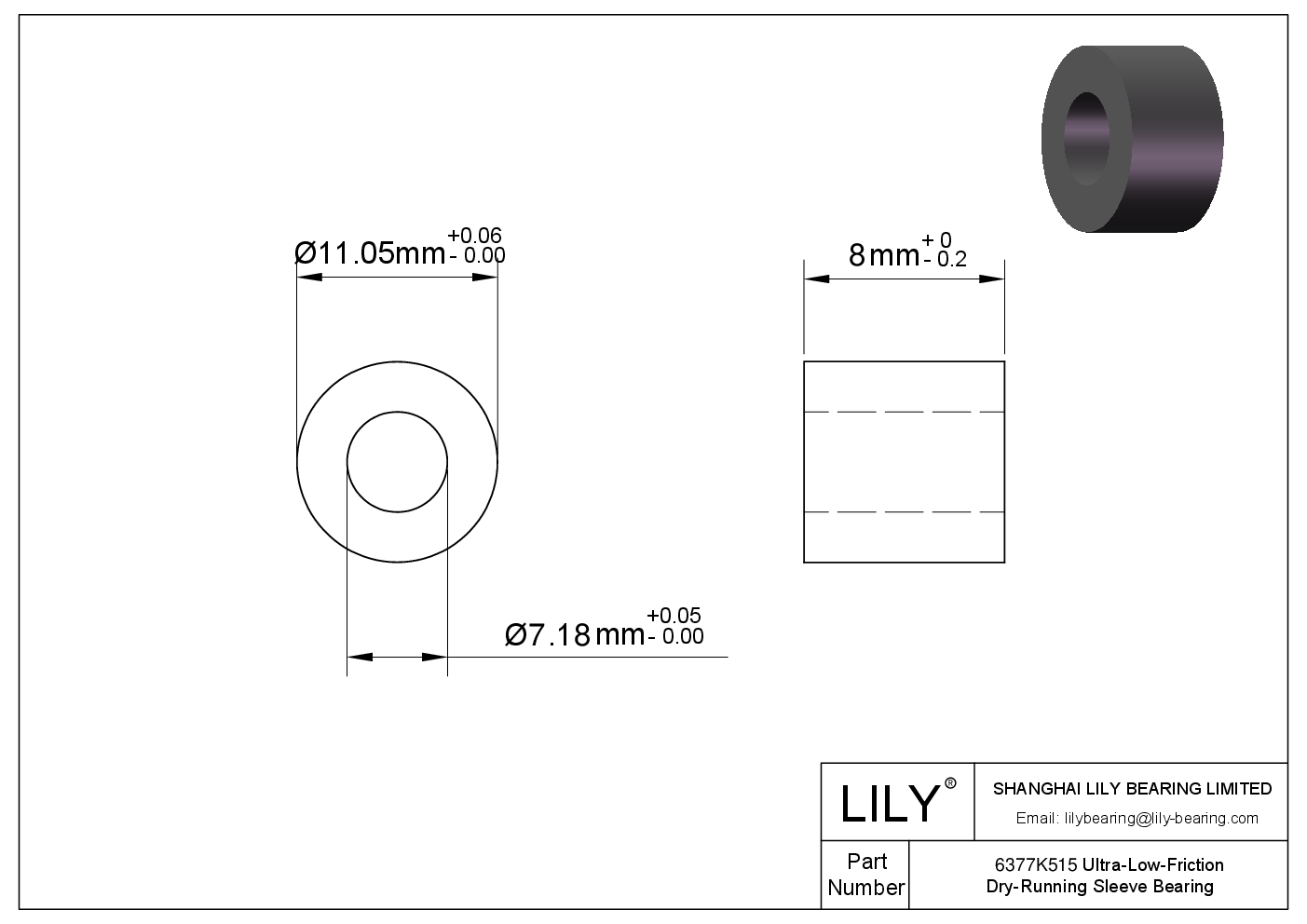

| Bore Dia | 7.18 mm |

| Bore Dia Tolerance | 0 mm to 0.05 mm |

| For Housing ID | 11mm |

| Outer Dia | 11.05 mm |

| Outer Dia Tolerance | 0 to 0.06 mm |

| Length | 8 mm |

| Length Tolerance | -0.2mm to 0mm |

| Dynamic Radial Load | 75 lbf |

| Static Radial Load | 75 lbf |

| Max Speed (X1000 rpm) | 0.12 |

| Material | Rulon J Plastic |

| Lubrication | Not Required |

| For Shaft Type | Round |

| Shaft Mount Type | Slip Fit |

| Temperature Range | -400° to 550° F |

| RoHS | Compliant |

| REACH | Compliant |

INTERCHANGE

The LILY Bearing part series GDHHKFBF is a potential replacement for these common bearing part numbers.

LILY

MCMASTER

GDHHKFBF

6377K515

Design Features of GDHHKFBF Bearing

GDHHKFBF Bearing consists of composite or engineered plastic material with self-lubricating additives. It has precise inner and outer diameters, wear-resistant surfaces, and strong reinforcement fibers. GDHHKFBF bore dia is 7.18 mm. Its outer dia is 11.05 mm. GDHHKFBF length is 8 mm. The bearing provides reliable performance and enhanced durability for industrial applications.

What Benefits Can GDHHKFBF Bearing Provide?

- Low Friction Coefficient: It helps cut down on energy loss, which in turn increases the efficiency and performance of the machinery.

- Dry-Running Capability:It does not require any lubricants. This reduces the need for maintenance and has a positive impact on the environment.

- Wear Resistance: The bearing lasts longer and performs well in tough conditions.

- Chemical Resistance: It works well with chemicals and withstands corrosion.

- Lightweight: Makes machinery lighter, which is helpful in many applications.

What Can GDHHKFBF Bearing Be Used for?

- Food and Beverage Industry: The bearing is perfect for machinery where the use of lubricants is not possible. This ensures smooth operation without the risk of contamination.

- Automotive: It can be employed in components where lubrication is difficult or impossible.

- Medical Devices: The bearing ensures clean and maintenance-free operation.

- Aerospace: It is suitable for applications requiring reliability and low maintenance.