Sign in

New customer? Start here

Cancel

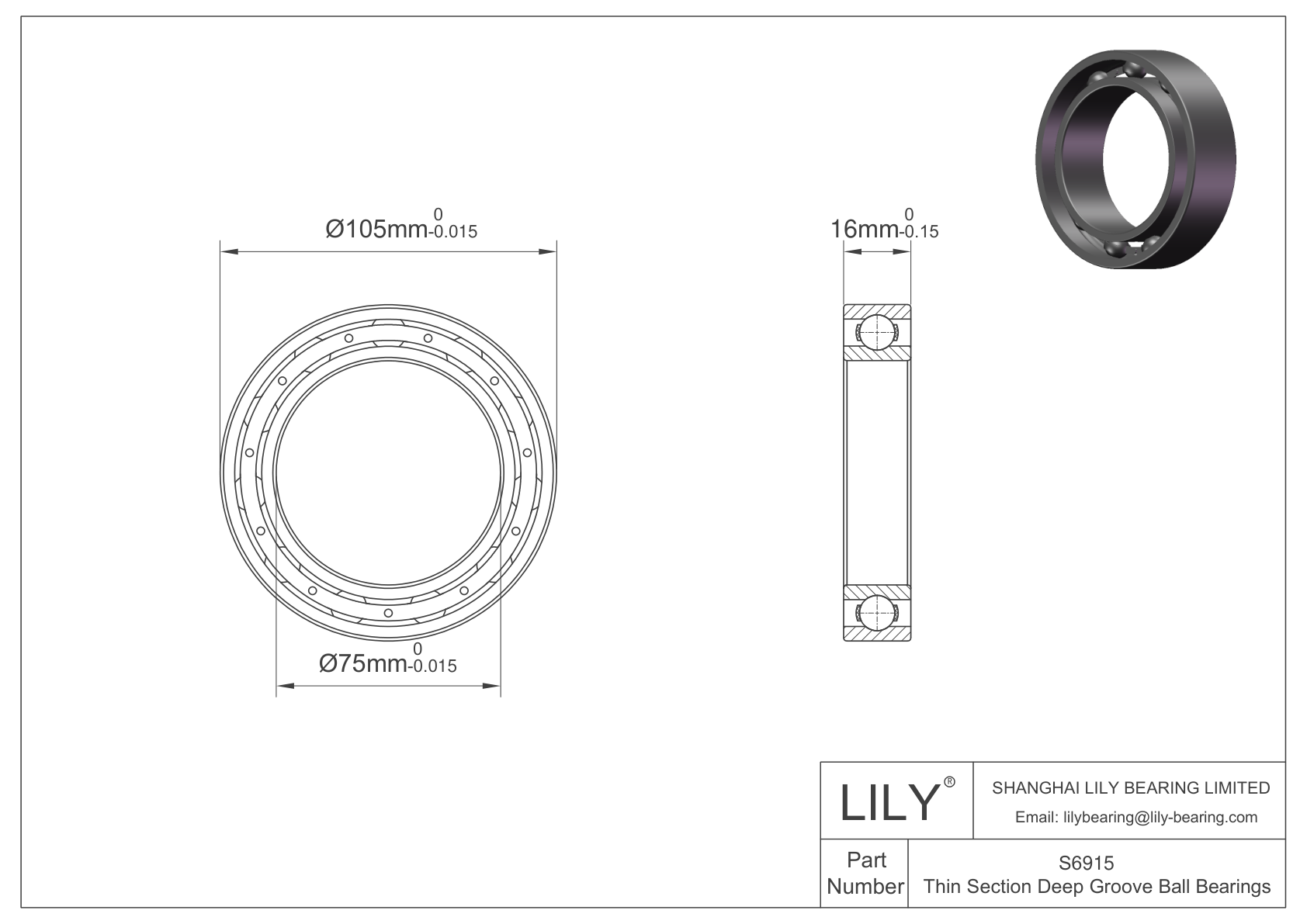

S6915

Price $ 18.50

| Part Number | S6915 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Seal Type | Open |

| Bore Dia | 75 mm |

| Bore Dia Tolerance | -0.015mm to 0 |

| Outer Dia | 105 mm |

| Outer Dia Tolerance | -0.015mm to 0 |

| Width | 16 mm |

| Width Tolerance | -0.150mm to 0 |

| Ring Material | 440C Stainless Steel |

| Ball Material | 440C Stainless Steel |

| Cage Material | 440C Stainless Steel |

| Dynamic Radial Load | 4856 lbf |

| Static Radial Load | 4573 lbf |

| Max Speed (X1000 rpm) | 6.39 |

| Lubrication | Required |

| Temperature Range | -86 to 230 °F |

| ABEC Rating | ABEC-1 |

| Radial Clearance Trade No | C0 |

| Radial Clearance | 0.01mm to 0.03mm |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 363 g |

Design Features of S6915 Bearing

S6915 Bearing represents a precise melding of advanced metallurgy and engineering. Crafted from AISI440C stainless steel, it is uniquely tailored for applications that require a combination of corrosion resistance and hardness. S6915 bore dia is 75 mm. Its out dia is 105 mm. Its width is 16 mm. S6915 Bearing offers a blend of durability, precision, and compatibility tailored for specific operational needs.

What Benefits Can S6915 Bearing Provide?

- Corrosion Resistance: Thanks to AISI440C stainless steel, this bearing is resilient against moisture and certain chemicals.

- Durability: AISI440C's hardness ensures long-lasting performance under heavy loads.

- Versatility: It operates effectively across diverse temperatures and conditions.

- Precision: Reduced friction for smoother operations and energy savings.

What Can S6915 Bearing Be Used for?

S6915 Bearing is commonly used in applications such as:

- Marine Applications: Its corrosion resistance makes it ideal for environments with moisture and salinity.

- High-Load Systems: The hardness of AISI440C ensures this bearing can handle heavy loads efficiently.

- Precision Equipment: Instruments requiring reduced friction and high accuracy benefit from this bearing.

- Extreme Conditions: Effective across varying temperatures and conditions, making it suitable for both hot and cold environments.