SMR2015C #3 LD

Price $ 9.15

Number

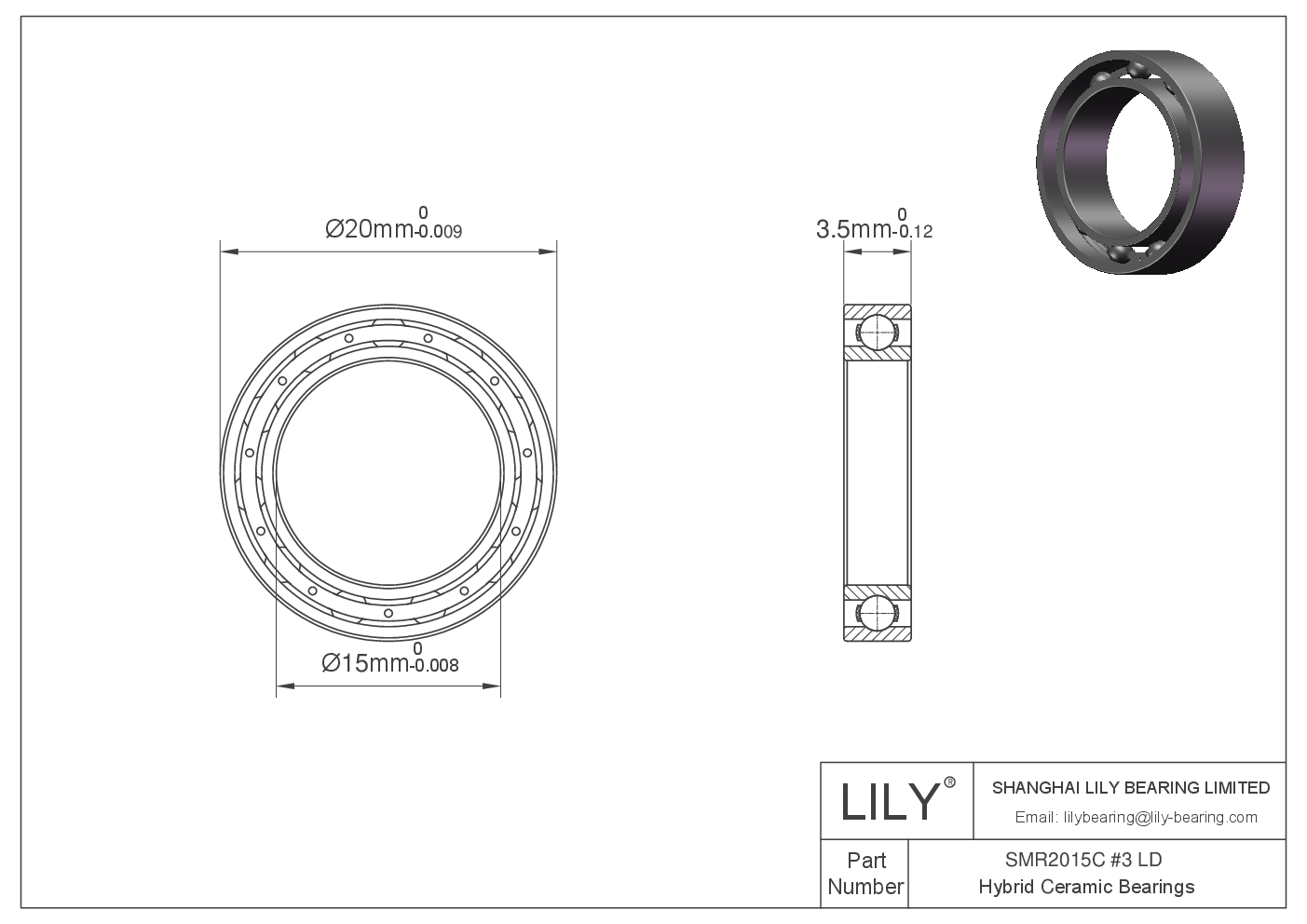

| Part Number | SMR2015C #3 LD |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

| Bore Dia | 15 mm |

| Outer Dia | 20 mm |

| Width | 3.5 mm |

| Ring Material | 440C Stainless Steel |

| Balls Material | Si3n4 |

| Cage Material | Stainless Steel |

| Lubrication | Ld Lube Dry |

| Shaft Mount Type | Press Fit |

| Temperature Range | -86 to 230 °F |

| ABEC Rating | Abec#3/isop6 |

| Radial Clearance Trade No | MC3 |

| Ball Grade | 5 |

| RoHS | Compliant |

| REACH | Compliant |

Design Features of SMR2015C #3 LD Bearing

SMR2015C #3 LD Bearing utilizes ceramic balls, typically made of silicon nitride (Si3N4), combined with steel inner and outer races. SMR2015C #3 LD bore dia is 15 mm. Its out dia is 20 mm. SMR2015C #3 LD width is 3.5 mm. This Ceramic Ball Bearing provides a sophisticated, high-performance solution that caters to the unique challenges presented by modern industrial and technological applications.

What Benefits Can SMR2015C #3 LD Bearing Provide?

- Reduced Friction: Ceramic's low frictional properties ensure smoother operation and decreased heat generation.

- Enhanced Durability: The wear-resistant nature of ceramic extends the bearing's lifespan, particularly in demanding conditions.

- Corrosion Resistance: Ceramic balls resist moisture and chemicals, safeguarding the bearing from corrosive environments.

- Electrical Insulation: Its non-conductive composition prevents electrical arcing, essential in electrically active setups.

- High-Speed Operation: Its attributes permit this bearing to operate efficiently at elevated rotational speeds.

What Can SMR2015C #3 LD Bearing Be Used for?

SMR2015C #3 LD Bearing is employed in various applications due to its unique characteristics. It can be used for:

- Electric Motors: Ideal for preventing electrical arcing, especially in electric vehicles.

- Precision Machinery: Suited for high rotational accuracy needs.

- Aerospace: Meeting the demands of wear resistance and thermal stability.

- High-Frequency Machining: Beneficial for high-speed spindles and machining centers.

- Harsh Environments: Resisting corrosion and withstanding extreme temperatures.

Recommended Products