Sign in

New customer? Start here

Cancel

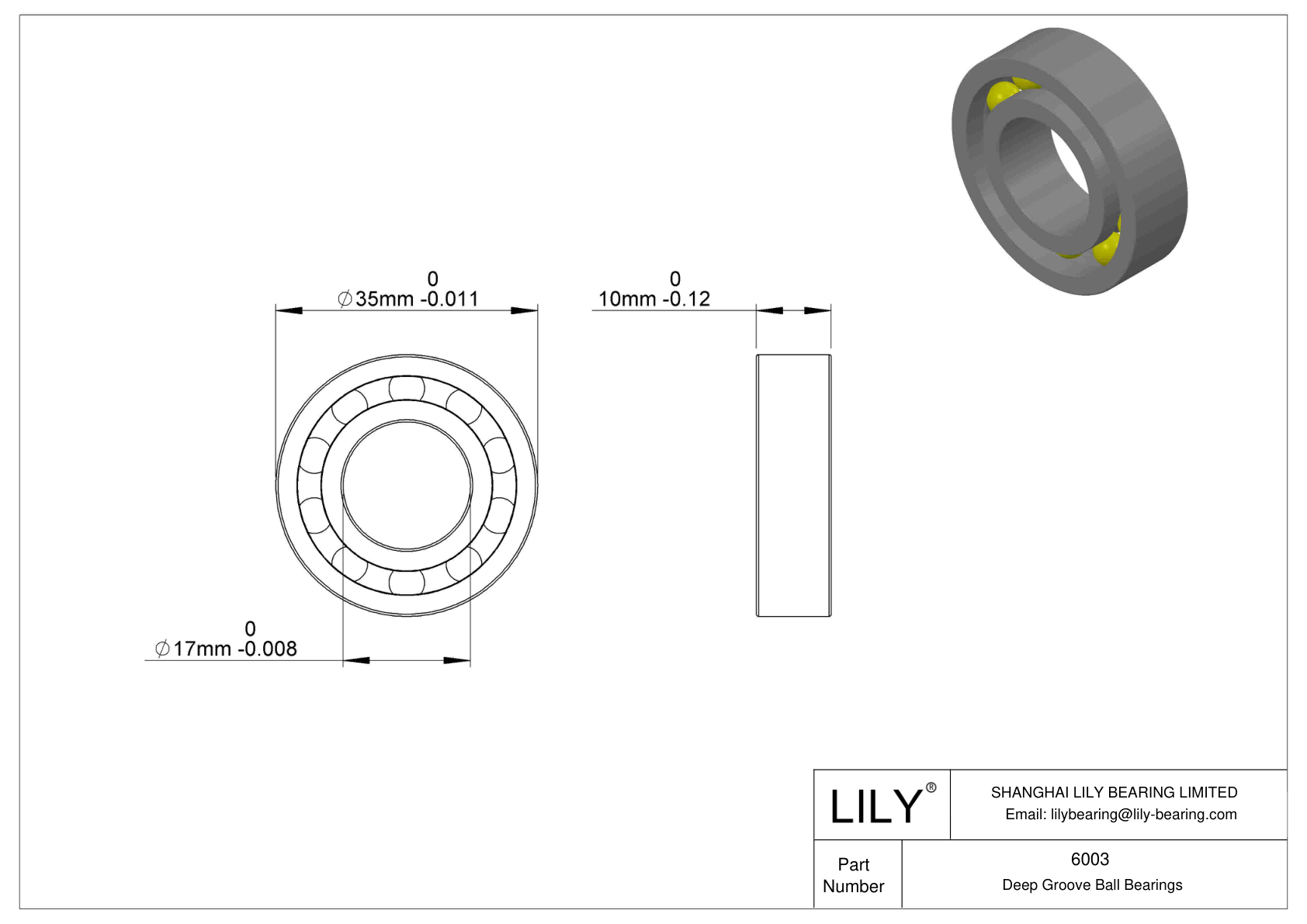

W6003-2Z W/MOLYKOTE G-4500

| Part Number | W6003-2Z W/MOLYKOTE G-4500 |

Brand: LILY  |

Interchangeable With: SKF |

| System of Measurement | Metric |

| For Load Direction | Radial |

| Construction | Single Row |

| Bearing Type | Ball |

| Seal Type | Shielded |

| Bore Dia | 17 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 35 mm |

| Outer Dia Tolerance | -0.011mm to 0 |

| Width | 10 mm |

| Width Tolerance | -0.120mm to 0 |

| Ring Material | Stainless Steel |

| Ball Material | Stainless Steel |

| Cage Material | Chrome Steel |

| Dynamic Radial Load | 1349 lbf |

| Static Radial Load | 731 lbf |

| Max Speed (X1000 rpm) | 21 |

| Lubrication | None |

| Temperature Range | -30°to 120 °C |

| ABEC Rating | ABEC 1 | ISO P0 |

| Radial Clearance Trade No | CN |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 39 g |

Design Features of W6003-2Z W/MOLYKOTE G-4500 Bearing

W6003-2Z W/MOLYKOTE G-4500 Bearing provides a robust and reliable bearing solution for applications requiring corrosion resistance and durability. W6003-2Z W/MOLYKOTE G-4500 bore dia is 17 mm. Its out dia is 35 mm. W6003-2Z W/MOLYKOTE G-4500 width is 10 mm. Its structural advantages combined with the inherent benefits of deep groove ball bearings make it an invaluable component in a wide range of specialized applications.

What Benefits Can W6003-2Z W/MOLYKOTE G-4500 Bearing Provide?

- Corrosion Resistance: The stainless steel material provides excellent resistance against corrosive elements.

- High Load Capacities: Similar to standard deep groove ball bearings, they can handle both radial and axial loads.

- Low Friction: Despite their specialized material, they still offer low friction coefficients for high-speed operations.

- Extended Service Life: Due to their enhanced durability, these bearings generally have a longer service life, especially in corrosive environments.

What Can W6003-2Z W/MOLYKOTE G-4500 Bearing Be Used for?

W6003-2Z W/MOLYKOTE G-4500 Bearing is used for a wide range of applications, such as:

- Food & Beverage Industry: Often used in processing equipment that is frequently exposed to water and other liquids.

- Chemical Processing: Ideal for machinery exposed to aggressive chemicals.

- Marine Applications: Useful in environments with exposure to saltwater.

- Pharmaceuticals: Used in equipment that must adhere to strict hygiene and cleanliness standards.

- Medical Devices: In devices where non-corrosive properties are essential for long-term reliability.

Recommended Products