10 Benefits of Polyurethane Rollers in Your Machinery

Polyurethane rollers have become a staple in various industries due to their versatility and superior performance. When compared to traditional materials like natural rubber, polyurethane offers several advantages that make it an ideal choice for machinery used in production lines, assembly lines, and material handling. In this article, we'll explore the top 10 benefits of using polyurethane rollers in your machinery.

Top 10 Advantages of Polyurethane Rollers

High Load Bearing Capacity

One of the most significant advantages of polyurethane rollers is their high load-bearing capacity. These rollers can handle heavier loads compared to natural rubber and other materials, making them perfect for industrial applications. This higher load capacity ensures that machinery runs smoothly and efficiently, reducing downtime and maintenance costs.

Abrasion Resistance

Polyurethane rollers are known for their excellent abrasion resistance. This means they can withstand wear and tear better than rubber rollers, which is crucial for maintaining the quality and efficiency of your production line. Abrasion resistance extends the service life of the rollers, making them a cost-effective choice for long-term use.

Chemical Resistance

In many industrial settings, machinery is exposed to various chemicals that can degrade traditional materials like rubber. Polyurethane rollers offer superior chemical resistance, making them suitable for use in environments where exposure to oils, solvents, and other chemicals is common. This chemical resistance ensures that the rollers maintain their integrity and performance over time.

High Tensile Strength

Polyurethane rollers boast high tensile strength, which means they can withstand significant stress without breaking or deforming. This property is particularly important in applications that involve high-speed operations or heavy loads. The high tensile strength of polyurethane ensures that the rollers remain reliable and effective, even under challenging conditions.

Versatility

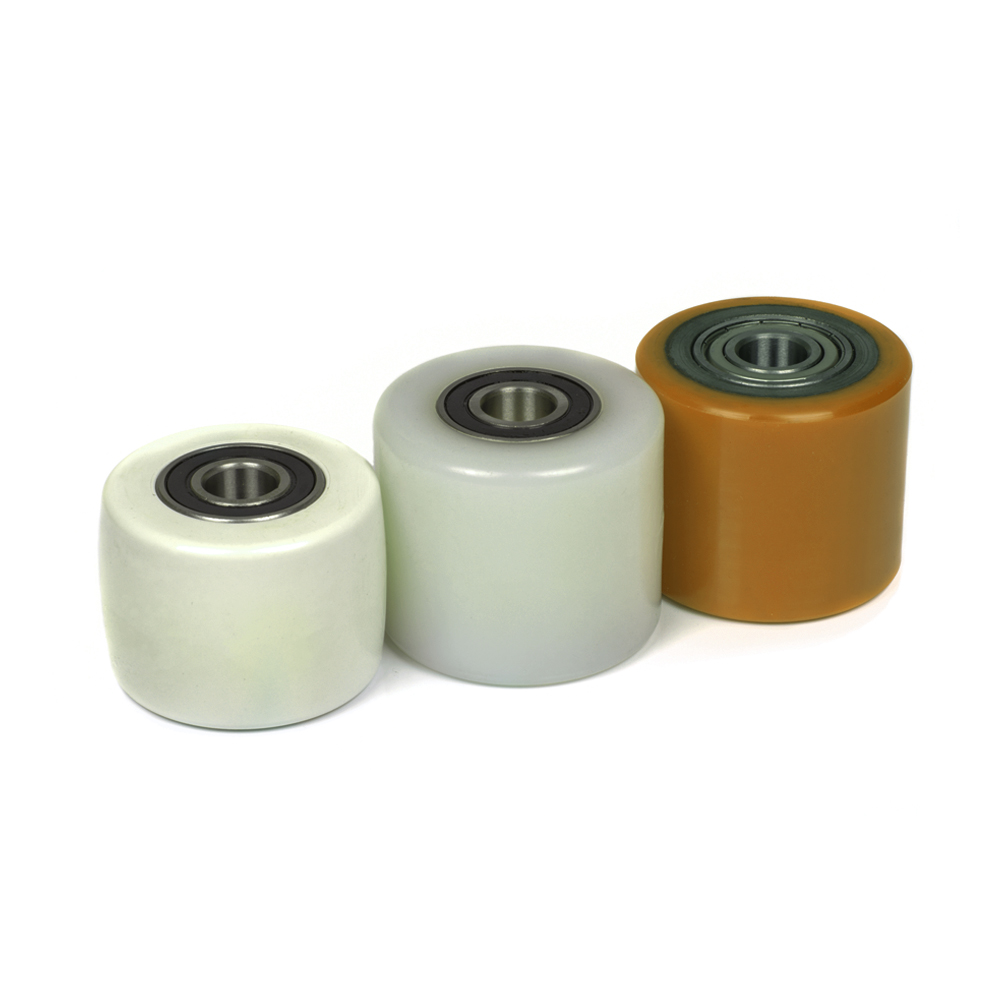

Polyurethane rollers are incredibly versatile and can be customized to meet the specific needs of various industries. They are available in a wide range of sizes, shapes, and hardness levels, allowing you to choose the perfect roller for your application. This versatility makes polyurethane an excellent choice for diverse industries, including food processing, automotive, and manufacturing.

Noise Reduction

One of the lesser-known benefits of polyurethane rollers is their ability to reduce noise levels. Unlike metal or harder materials, polyurethane rollers absorb vibrations and reduce noise, creating a quieter working environment. This noise reduction is particularly beneficial in assembly lines and production facilities where noise can be a significant issue.

Enhanced Grip

Polyurethane rollers offer excellent grip, which is essential for applications that require precise control and movement. This enhanced grip ensures that materials are handled accurately and efficiently, reducing the risk of slippage and improving overall productivity. Whether you're working with delicate items or heavy loads, polyurethane rollers provide the necessary traction for optimal performance.

Improved Energy Efficiency

The properties of polyurethane rollers contribute to improved energy efficiency in machinery. Their low rolling resistance means that less energy is required to move them, reducing the overall energy consumption of your equipment. This energy efficiency not only lowers operational costs but also contributes to a more sustainable and environmentally friendly production process.

Longer Service Life

Polyurethane rollers are designed to last longer than their rubber counterparts. Their resistance to abrasion, chemicals, and wear and tear means they require less frequent replacement, leading to lower maintenance costs and reduced downtime. The longer service life of polyurethane rollers makes them a cost-effective investment for any industrial application.

High Quality and Consistency

Polyurethane rollers are manufactured using advanced processes that ensure high quality and consistency. This precision manufacturing results in rollers that meet strict performance standards and deliver reliable results. High-quality polyurethane rollers contribute to the smooth operation of your machinery, reducing the risk of unexpected failures and ensuring consistent output.

Applications of Polyurethane Rollers

Polyurethane rollers are used in a wide range of applications across various industries. Here are some common uses:

Manufacturing Process

In the manufacturing process, polyurethane rollers are used for material handling, conveyor systems, and various other applications that require durable and reliable rollers. Their high load-bearing capacity and abrasion resistance make them ideal for these demanding environments.

Food Processing

Polyurethane rollers are also widely used in the food processing industry. Their chemical resistance and ability to withstand high temperatures make them suitable for use in food production lines. Additionally, their ability to reduce noise and absorb vibrations ensures a quieter and more efficient production environment.

Automotive Industry

In the automotive industry, polyurethane rollers are used in assembly lines and other applications that require precise control and movement. Their enhanced grip and high tensile strength ensure that components are handled accurately and efficiently, improving overall productivity.

Material Handling

Polyurethane rollers are commonly used in material handling applications, including conveyor systems, packaging machinery, and more. Their high load-bearing capacity, abrasion resistance, and versatility make them an excellent choice for these applications.

Conclusion

Polyurethane rollers offer numerous benefits that make them an ideal choice for various industrial applications. Their high load-bearing capacity, abrasion resistance, chemical resistance, and versatility ensure that they perform reliably and efficiently in demanding environments. Additionally, their noise reduction, enhanced grip, improved energy efficiency, longer service life, and high quality make them a cost-effective investment for any machinery.

By choosing polyurethane rollers, you can enhance the performance and longevity of your equipment, reduce maintenance costs, and improve overall productivity. Whether you're in manufacturing, food processing, automotive, or material handling, polyurethane rollers provide the durability and reliability you need to keep your operations running smoothly.

Keep Learning