Sign in

New customer? Start here

6205Z Bearing vs. 6205ZZ: Understanding the Differences

The 6205 series of deep groove ball bearings are versatile components known for their durability and reliability. They have a simple design with a deep groove that allows them to handle both radial and axial loads efficiently. Choosing the right bearing is important because it affects how well a machine works and how long it lasts.

In this blog, we will focus on comparing two popular bearings: the 6205Z and the 6205ZZ. We’ll explore the differences between them and determine which one might be more suitable for your needs.

What Are Deep Groove Ball Bearings?

Key Features of Deep Groove Ball Bearings

- Low Friction and High-Speed Capability: Designed to reduce friction, allowing smooth operation even at high speeds.

- Handles Radial and Axial Loads: They can bear forces from both sides as well as from the top and bottom, which makes them highly versatile.

- Versatility: Deep groove ball bearings are used in many industries, like cars and machines.

Role of Shields and Seals in Bearings

Shields (Z and ZZ) in bearings serve important purposes:

- Protection Against Contaminants: The shields keep dust, dirt, and other small particles out of the bearing. This keeps the bearing clean and reduces the chance of wear and damage.

- Retention of Lubrication: Shields keep the grease or oil inside the bearing and stop dirt from getting in. This keeps the bearing running smoothly and efficiently, which reduces friction and heat.

6205Z Bearing Overview

The 6205Z bearing has a deep groove design that lets it handle both sideways and straight loads, making it useful in many applications. It has a metal shield on one side that keeps dust and dirt out while holding the lubricant inside. This bearing is made from strong materials and includes steel balls. It also has inner and outer rings for reliable and long-lasting performance.

Technical Specifications:

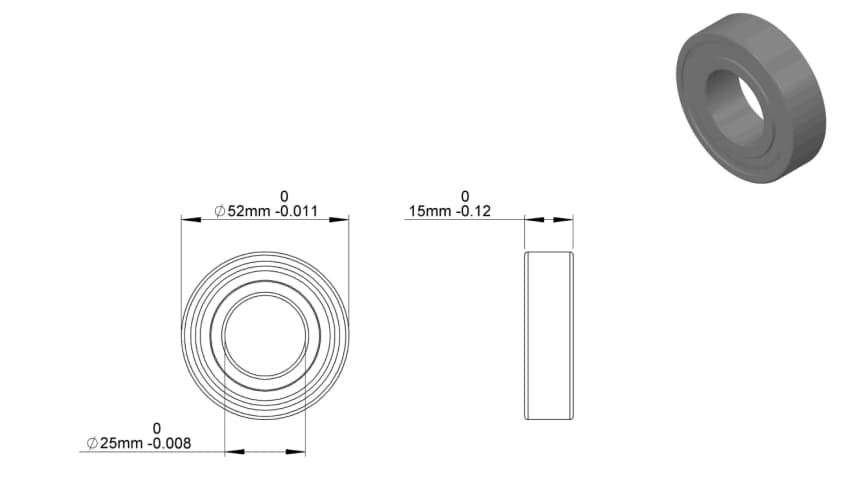

- Bore diameter: 25 mm, outer diameter: 52 mm, width: 15 mm. (bearings 25x52x15mm)

- Material: 6205Z Bearing is made from high carbon chrome steel, which makes it durable and resistant to wear.

- Cage: Pressed steel cage that keeps the ball elements in place and supports smooth movement.

- Shield: Single metal shield (Z) on one side to prevent dust and contaminants from entering while retaining lubrication.

Applications of 6205Z Bearing

6205Z Bearing is suitable for medium to high-speed applications, such as electric motors, conveyors, and pumps. This bearing is ideal for areas where there is little contamination.

Key Features

- Single Shield: The 6205Z bearing has a single shield that offers good protection against dirt and dust.

- Lower Friction: 6205Z Bearing Offers reduced friction compared to fully sealed bearings.

- Heat Dissipation: 6205Z Bearing helps remove heat easily, making it great for high-speed operations.

6205ZZ Bearing Overview

The 6205ZZ bearing features a deep groove design that enables it to effectively handle both lateral and axial loads. It has metal shields on both sides to keep out dust and dirt while keeping the lubricant inside. Made from strong materials, this bearing is built to last and work reliably in many different uses.

Technical Specifications:

- Bore diameter: 25 mm, outer diameter: 52 mm, width: 15 mm.

- Shields on Both Sides: The 6205ZZ bearing has shields on both sides, providing extra protection against dust and dirt.

Applications of 6205ZZ Bearing

The 6205ZZ bearing is widely used in environments where both dust and moisture are concerns. It can be found in automotive wheel assemblies, industrial machinery, and household appliances.

Key Features

- Double Shielded (ZZ): The 6205ZZ bearing offers superior protection against outside contaminants.

- Minimal Maintenance: It needs little upkeep because it has sealed lubrication.

- Ideal for Harsh Environments: Perfect for areas exposed to dust, dirt, and debris.

Comparing the 6205Z and 6205ZZ Bearings

Shielding

- 6205Z: Single metal shield on one side.

- 6205ZZ: Double metal shields on both sides.

Protection Against Contaminants

- 6205Z: 6205Z Bearing Provides limited protection, making it suitable for environments with less contamination.

- 6205ZZ: Offers better protection, making it ideal for harsher environments.

Lubrication and Maintenance

- 6205Z: 6205Z Bearing May require more frequent lubrication because of open side.

- 6205ZZ: Longer lubrication life, lower maintenance because of enclosed design.

Application Suitability

- 6205Z: Better suited for high-speed applications with limited exposure to contaminants.

- 6205ZZ: Ideal for environments with dust and moisture, requiring minimal maintenance.

Performance Comparison

Load Capacity

Both bearings have similar load capacities, but the 6205ZZ may last longer because of better protection.

Speed Capability

Both 6205Z and 6205ZZ offer high-speed performance, but 6205Z may have better heat dissipation for prolonged high-speed applications.

Durability and Lifespan

The 6205ZZ provides enhanced durability thanks to its better sealing. In contrast, the 6205Z may perform better in high-speed applications with minimal contamination.

How to Choose Between 6205Z and 6205ZZ Bearings

Consider the Operating Environment

- For cleaner environments with minimal debris, the 6205Z is a suitable and cost-effective option.

- For environments exposed to dust, dirt, or moisture, the 6205ZZ provides better protection and longevity.

Maintenance Requirements

- If minimal maintenance is preferred, the 6205ZZ with its sealed lubrication is the better option.

- For applications where periodic maintenance is possible, the 6205Z might offer slightly better speed performance.

Cost Considerations

The 6205ZZ typically costs more than the 6205Z because it has double shields that provide better protection and durability. This higher price reflects the extra materials and work needed to make it.

Influence on Purchasing Decisions:

In clean environments with little dust or dirt, the cheaper 6205Z may be enough and save money. Users in these cases often focus on staying within their budget and might prefer the simpler design.

On the other hand, in situations with dust, moisture, or high speeds, spending more on the 6205ZZ could be a good investment. Its better sealing and durability can reduce maintenance costs and make it last longer. Even if it costs more at first, it becomes a more cost-effective option over time.

Conclusion

The 6205Z and 6205ZZ bearings are different in protection and maintenance. The 6205Z has one shield for moderate protection, while the 6205ZZ has two shields for better protection and requires less maintenance. The 6205Z is great for clean, high-speed uses, whereas the 6205ZZ is ideal for dustier or tougher environments. When choosing a bearing, consider your specific needs, such as load, speed, and exposure to dirt.

Keep Learning