LILY’s Recent Large Slewing Bearing for a Telescope Customer

Industry Potential of Antennas and Telescopes

During the transition from 4G to 5G, antenna technology has been continuously advancing, including perceptive antennas, large-scale array antennas, wideband miniaturized electronically tunable antennas, and so on.

As the application of 5G technology deepens and the development of future 6G technology progresses, the antenna industry will face more technological challenges and market opportunities. Antenna technology will continue to innovate and upgrade to meet the growing communication demands.

Bearing Solutions for Antenna and Telescopes

Slew bearings play a significant role in antennas and telescopes for the following reasons:

l Support and Rotation: Slew bearings are crucial in antennas and telescopes, supporting the upper structure and enabling rotation. These bearings are typically used in equipment that requires a combination of large diameters and loads, such as cranes, excavators, radars, wind turbines, and material handling equipment. In antennas and telescopes, slew bearings are also used to support and rotate the antenna or the telescope tube, allowing it to point in various directions.

l High Precision and Low Friction: Slew bearings in antennas and telescopes need to have characteristics of high precision and low friction. Rolling element bearings and hydrostatic bearings are widely used in large telescopes because they operate with low friction, generate minimal heat, and require little maintenance. This feature is essential for maintaining the pointing accuracy of antennas and telescopes.

l Stability and Rigidity: The design of slew bearings usually takes into account their rigidity and stability. For example, the altitude bearings of the VLT (Very Large Telescope) increase the overall system rigidity by adding pads at both axial ends, thereby enhancing the telescope's resistance to wind disturbance. This design ensures the stability and accuracy of the telescope under adverse conditions.

l Complex Motion Control: In the applications of antennas and telescopes, slew bearings need to handle complex motion control. For instance, in the SCOLE (Spacecraft Control Laboratory Experiment) project, slew bearings must not only perform large-angle movements but also control vibrations, requiring complex control schemes to ensure system stability and accuracy.

l Adaptation to Extreme Environments: The performance of slew bearings in extreme environments is particularly important. For example, the skew-axis astronomical telescope, due to its unique structural form, is more adapted to extreme site environments such as Antarctica. This adaptability ensures the normal operation of the telescope under harsh conditions.

l Maintenance and Replacement Costs: The design and maintenance costs of slew bearings are also part of their significance. Although slew bearings may be costly in some applications, their low-friction and high-rigidity characteristics provide a high cost-performance ratio over long-term operation.

LILY Bearing’s Production Expertise

Since its inception, LILY has been developing and producing bearing solutions for different types of precision machines, highlighting the company's extensive experience and expertise in this field.

LILY’s main bearings are among the key components for antenna and telescopes and thus contribute to the expansion of renewable energies.

A Recent Case Study: Bearing Features and Specifications for a Telescope Manufacturer

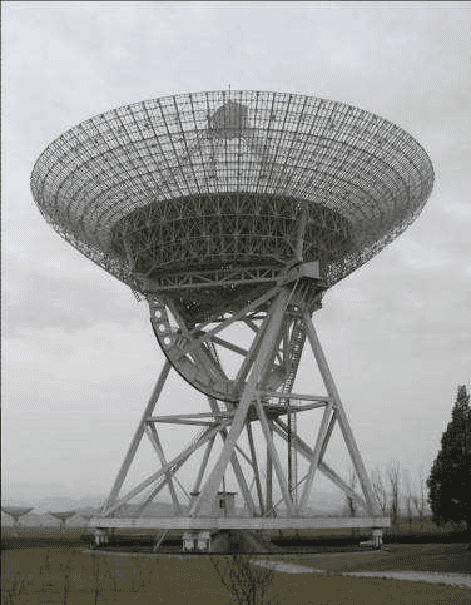

Recently, Lily Bearing delivered a large cross-roller slew bearing for a telescope manufacturer (See the pictures below).

The installation of the large bearing on site:

Heat treatment:

The end equipment of the large bearing customer:

Here is a summary of the large cross-roller bearing by LILY:

|

Feature/Specification |

Description |

|

Structural Design |

Cross-roller structure with an 8.5m outer diameter for massive load support and enhanced stability. |

|

Precision Requirements |

Axial clearance of 0.4 mm, outer ring runout at 0.1 mm, and inner ring runout at 0.3 mm for high operational precision. |

|

Load Capacity |

Designed to handle 120 tons, showcasing robust materials and engineering. |

|

Rotational Speed |

0.25 RPM for slow and controlled operation, ideal for precise positioning in telescopes and antennas. |

|

Operational Durability |

Built for continuous 16-hour daily operation with a 20-year lifespan, reflecting exceptional endurance. |

|

Material and Manufacturing |

Utilizes high-grade materials with meticulous machining and stringent quality control for mechanical strength and dimensional stability. |

Where large cross-roller slewing bearings are used outside antenna and telescope

Large cross-roller slewing bearings serve critical roles in diverse industries due to their high load capacity and precision. They are vital in heavy construction machinery, radar and surveillance systems, wind turbines, material handling, marine applications, aerospace, oil and gas rigs, medical imaging, entertainment rides, and agricultural equipment.

The main bearings from LILY, known for their robust design and excellent performance, are a testament to the level of precision required in engineering. Contact us to find more about large cross-roller slew bearing solutions and more.

Keep Learning