Cam Follower: Stud Type VS Yoke Type

In the heart of industrial machinery, where precision meets motion, cam followers play a pivotal role. These small yet powerful parts are crucial for the smooth running of countless systems, making sure that each turn of a cam leads to steady, dependable straight-line movement.

In this blog post, we'll dive into the world of cam followers, with a spotlight on two of the most prevalent types: Stud Type and Yoke Type. Our aim is to shed light on their differences, helping you make an informed choice for your specific industrial needs.

Understanding Cam Followers

Definition and Function

Cam followers are special ball bearings made to track the shape of a camshaft, turning spinning motion into straight-line motion. They are the unsung heroes within machines, quietly reducing friction and wear in linear motion systems. This leads to improved efficiency and extends the lifespan of the equipment. Packed with rollers, these followers guarantee minimal bending and smooth running.

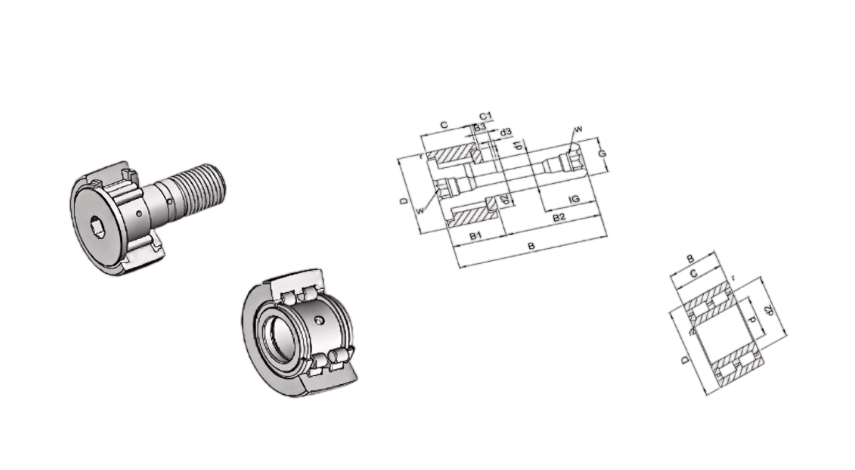

Stud Type Cam Followers

Design and Structure

At the core of a stud type cam follower bearing is a solid stud, which replaces the traditional inner ring. This design is complemented by an integral rib and a robust, thick-walled outer ring. Lubrication paths—such as threaded-end, head-end, and cross-drilled holes—are vital for maintaining the longevity and smooth operation of these components. Stud types of cam followers are known for their high-quality performance and ease of integration into motion systems.

Applications

Stud type cam followers excel in applications where they serve as track rollers. They are particularly well-suited for systems that demand minimal deflection and can handle moderate loads with ease. The heavy stud design reduces friction and is ideal for roller bearing applications.

Advantages

The stud type cam followers are known for their easy installation and maintenance, which are significant advantages. Their design facilitates simple integration into current systems. Moreover, as stud type cam followers are capable of handling moderate loads and can resist occasional shocks, they're suitable for a wide range of uses.

Yoke Type Cam Followers

Design and Structure

Yoke type cam followers boast a unique design featuring a pin with straddle or yoke support. This configuration enhances load distribution, making them ideal for high-load applications. A lubrication groove is a crucial feature that helps keep the bearing clean and ensures it runs smoothly. The roller cam in yoke types is designed for heavy duty applications.

Applications

Yoke type cam followers are commonly selected for heavy-duty applications and scenarios with potential. Their design ensures that they can maintain performance even under challenging conditions.

Advantages

Yoke-type cam followers distribute loads evenly and use a high-strength pin, allowing them to easily handle heavy loads and repeated shocks. Their robust construction is a testament to their ability to provide reliable service in demanding environments.

Comparison of Stud Type and Yoke Type Cam Followers

Load Handling Capacity

When comparing the load-handling capacities of stud-type and yoke-type cam followers, yoke types clearly perform better in high-load situations. However, for moderate load applications, stud types provide a suitable and cost-effective solution.

Installation and Maintenance

Both types come with their specific installation and maintenance needs. Stud types are usually easier to install thanks to their simple design. On the other hand, yoke types might need extra attention to guarantee even load distribution and correct alignment.

Specific Tools for Stud and Yoke Type Cam Followers:

- Torque wrench: To ensure the studs are tightened to the correct specification.

- Socket set: For removing and installing nuts and bolts.

- Alignment tools: Such as laser alignment devices or mechanical alignment gauges to ensure proper positioning.

- Thread-locking compound applicator: To prevent studs from loosening over time.

Procedures for Stud and Yoke Type Cam Followers:

- Before installation, thoroughly inspect the cam followers for any signs of damage, cracks, or excessive wear.

- Clean the mating surfaces where the cam followers will be installed to remove any debris or contaminants.

- Apply an appropriate lubricant to the contact areas of the cam followers to reduce friction.

- Install the studs and use the torque wrench to tighten them to the manufacturer's specified torque value.

- Align the yoke precisely using the alignment tools to ensure smooth and accurate operation.

- After installation, conduct a test run to check for any abnormal noises, vibrations, or misalignments.

- Regularly inspect and maintain the cam followers according to the equipment maintenance schedule to ensure their longevity and optimal performance.

Durability and Lifespan

The durability and lifespan of cam followers are influenced by factors such as material quality, design, and lubrication practices. Yoke types, with their better load distribution, often last longer in high-load applications. In contrast, stud types may require more frequent maintenance.

Table 1 Stud vs Yoke Type Cams in Durability and Lifespan

|

|

Stud Type Cam Followers |

Yoke Type Cam Followers |

|

Durability |

Can be highly durable depending on the material and design. |

Generally offer good durability, but may vary based on specific design and usage. |

|

Lifespan |

May have a longer lifespan in certain heavy-duty applications where stability is crucial. |

Can have a decent lifespan, often suitable for a wide range of moderate-duty operations. |

Table 2 Factors Influencing Lifespan of Stud vs Yoke Type Cams

|

Factors Influencing Lifespan |

Stud Type Cam Followers |

Yoke Type Cam Followers |

|

Material Quality |

High-quality materials enhance durability and lifespan. Poor materials can lead to premature wear. |

Similar to stud type, quality of materials is critical for longevity. |

|

Lubrication Practices |

Adequate and proper lubrication significantly extends lifespan. Inadequate lubrication causes increased friction and wear. |

Correct lubrication is essential for smooth operation and longer life. Poor lubrication can reduce lifespan. |

|

Load and Operating Conditions |

Heavy loads and harsh operating conditions can impact durability. Well-designed stud type can handle higher loads. |

Operating conditions and load capacity affect lifespan; may be less suitable for extremely heavy loads. |

|

Installation Accuracy |

Precise installation ensures even load distribution and longer life. Incorrect installation can cause uneven wear |

Accurate installation is important for optimal performance and lifespan. |

Selecting the Right Cam Follower for Your Application

Factors to Consider when Selecting the Right Types of Cam Follower

|

Key Factors to Consider |

Stud Type Cam Followers |

Yoke Type Cam Followers |

|

Load Capacity |

Handles higher loads; suitable for heavy-duty applications. |

Suited for moderate loads; may struggle with extremely heavy loads. |

|

Precision Requirements |

Offers higher precision and stability; crucial in demanding applications. |

Provides decent precision but might be slightly less precise. |

|

Space Constraints |

May occupy more space depending on the design. |

Can be more compact in some cases; suitable for space-limited setups. |

|

Maintenance Accessibility |

Maintenance can be more challenging. |

Generally, easier to access and maintain. |

|

Cost |

Typically more expensive. |

Usually less costly. |

|

Load Requirements |

Preferred for heavy and consistent loads. |

Adequate for moderate loads and applications with less extreme load variations. |

|

Environmental Conditions |

May have an edge in durability in harsh and corrosive environments if properly protected. |

Both types of cam may require protective measures; performance can vary. |

|

Installation Constraints |

Requires more precise alignment and specific torque settings. |

Usually easier to install but still needs proper alignment. |

Expert Recommendations

|

Common Industrial Applications |

Recommended Cam Follower Type |

|

Heavy machinery manufacturing |

Stud type for higher load capacity and stability. |

|

Automotive assembly lines |

Stud type if high loads and precision are needed; yoke type for moderate load and ease of installation in some areas. |

|

Textile machinery |

Yoke type might be sufficient for most operations, but stud type for critical components. |

|

Packaging equipment |

Yoke type for its ease of installation and moderate load handling; stud type for heavy-duty parts. |

Remember, every industrial application comes with its own set of demands and conditions. For tailored advice, it's a good idea to seek out experts with extensive field knowledge.

They can closely examine your specific parameters, working environment, and performance goals to provide precise guidance on choosing the right cam follower type. In this way, your machinery and equipment can perform at their best, offering reliability and durability suited to your industrial needs.

Conclusion

In conclusion, choosing between stud type and yoke type cam followers depends on the specific needs of your application. By understanding the unique benefits of each type, you can make an informed decision for optimal performance and longevity. We invite you to contact us for further assistance or to explore our range of high-quality cam followers to find the perfect fit for your machinery.

Keep Learning