Food-Grade Polyurethane Rollers: Safe and Effective

CONTENTS

- Understanding Polyurethane Rollers

- Advantages of Polyurethane Rollers in the Food Industry

- Applications of Polyurethane Rollers in the Food Industry

- Compliance and Standards for Food-Grade Polyurethane Rollers

- Case Studies

- Choosing the Right Polyurethane Rollers for Your Food Industry Needs

- Maintenance and Care for Polyurethane Rollers

Polyurethane rollers play a vital role in the food and beverage industry, providing excellent safety, efficiency , and durability that other materials like rubber rollers cannot match. In this blog, we’ll cover why food-grade polyurethane rollers are so important, their key benefits, and how they meet industry standards. We'll also look at how these rollers help keep food safe while boosting production efficiency.

Understanding Polyurethane Rollers

What are Polyurethane Rollers?

Polyurethane rollers are industrial parts made from a strong, flexible material called polyurethane.

- Known for their strength and durability

- Used in a wide range of industrial applications like material handling and conveyor systems in food processing plants

- Especially important because they can endure tough conditions and still perform reliably

- Their resistance to abrasion and chemical resistance make them a cost-effective solution.

Types of Polyurethane Rollers

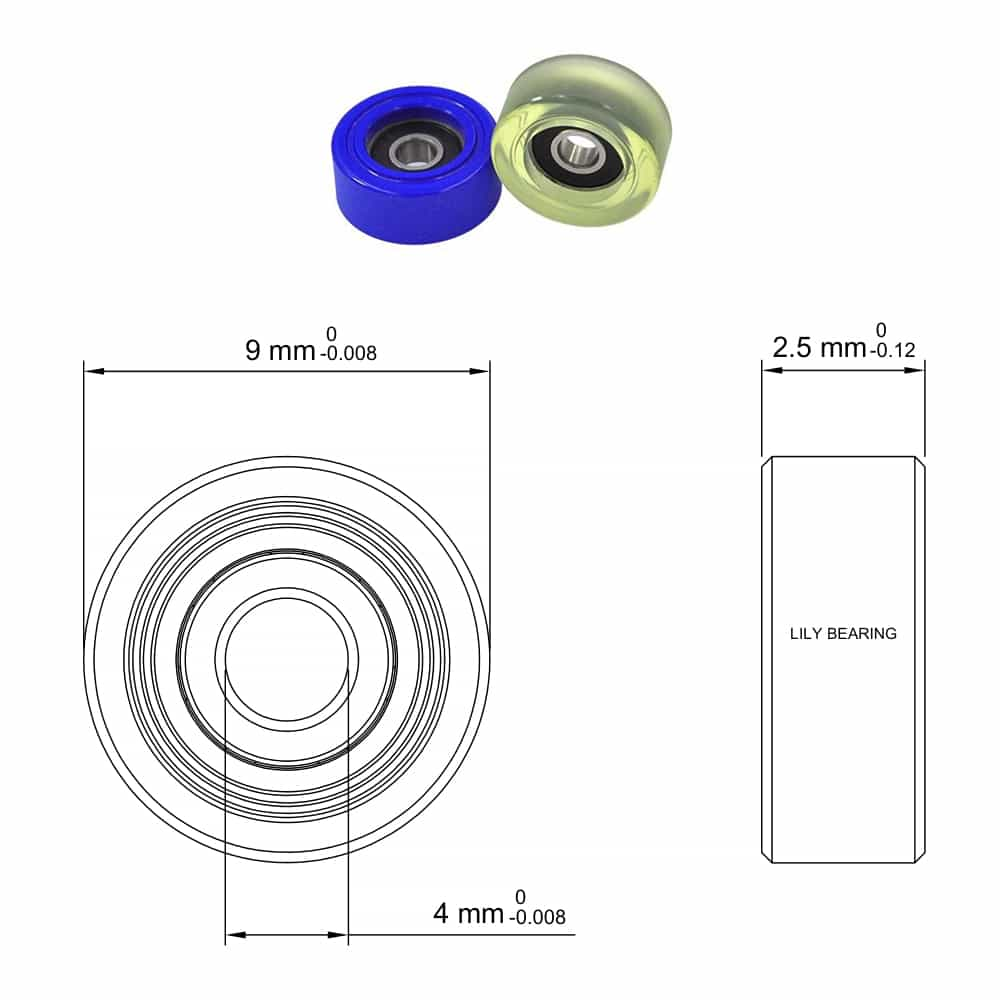

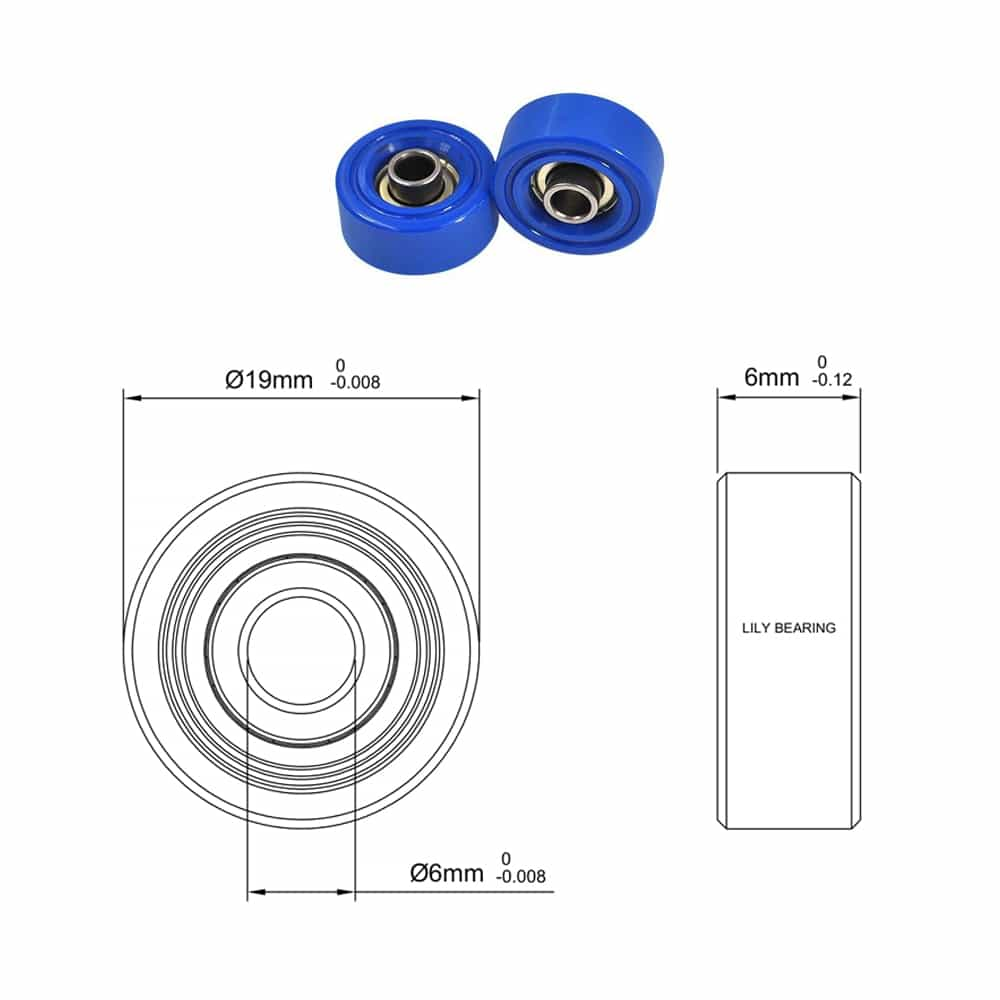

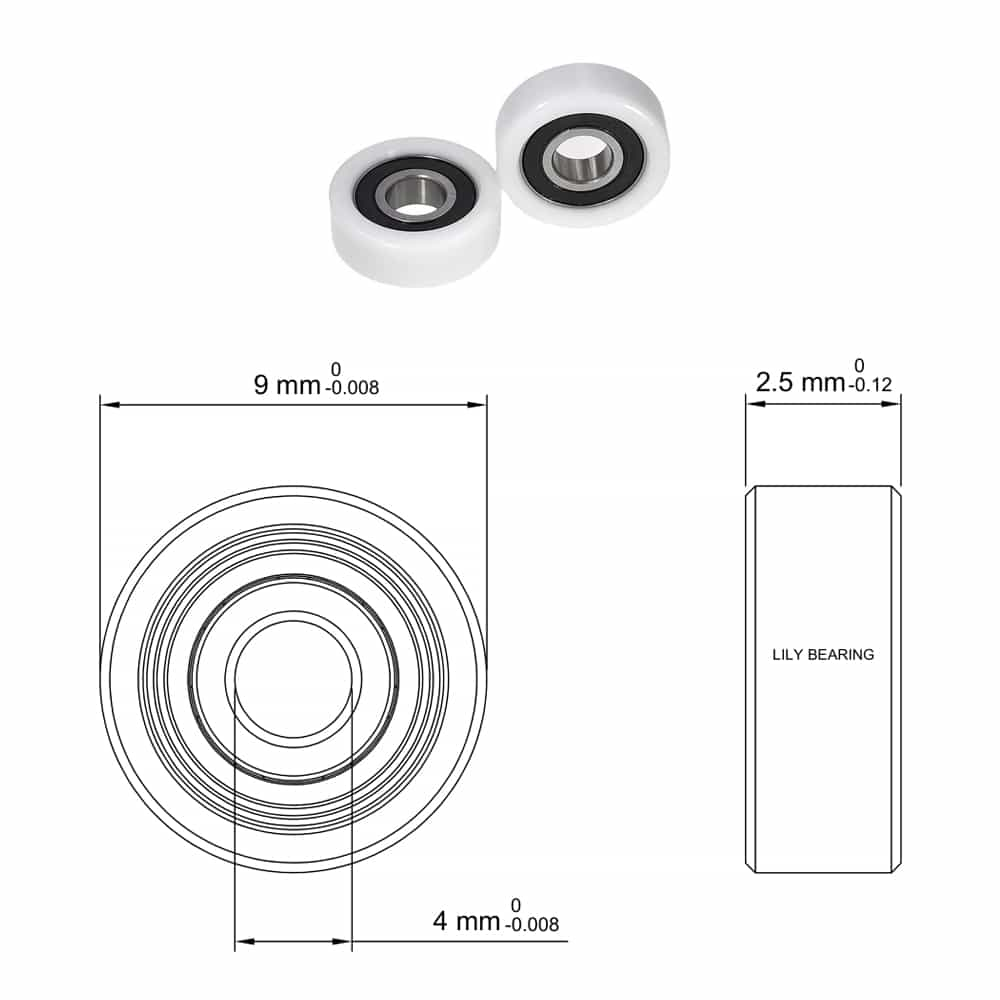

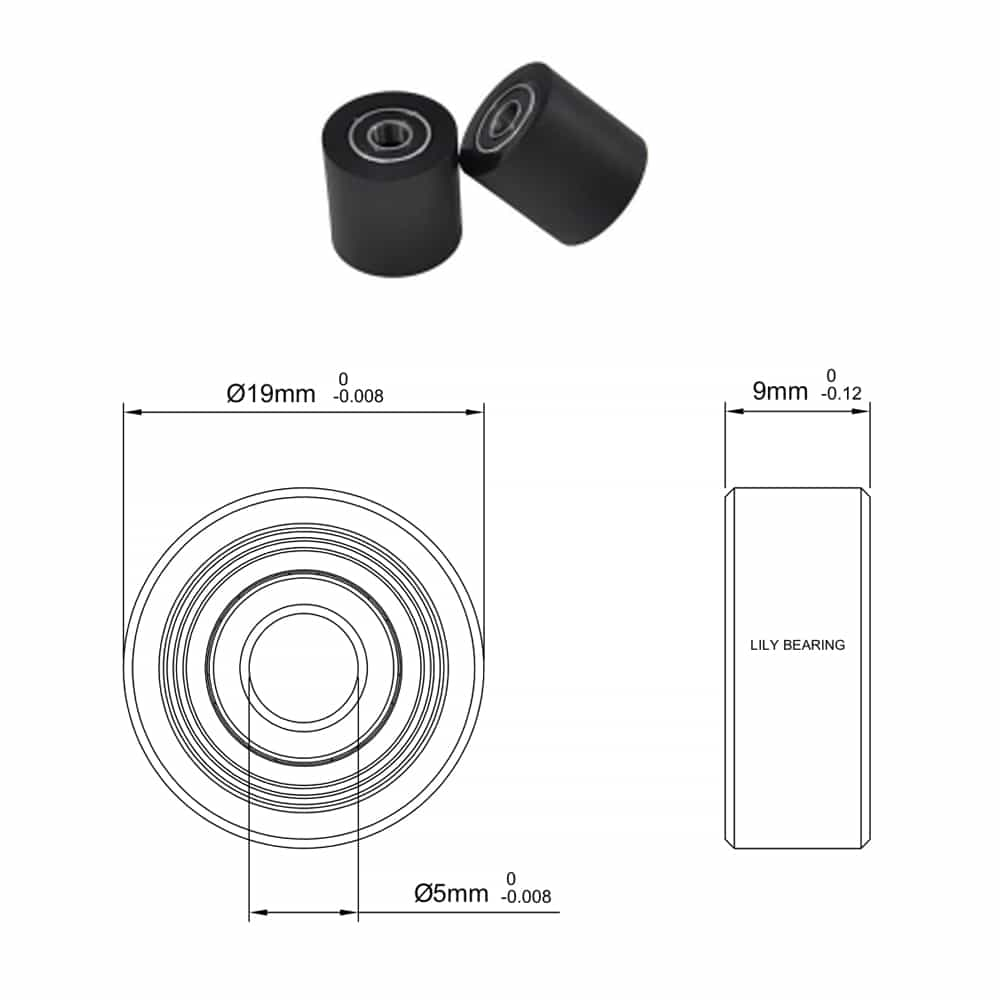

Polyurethane Coated Bearings

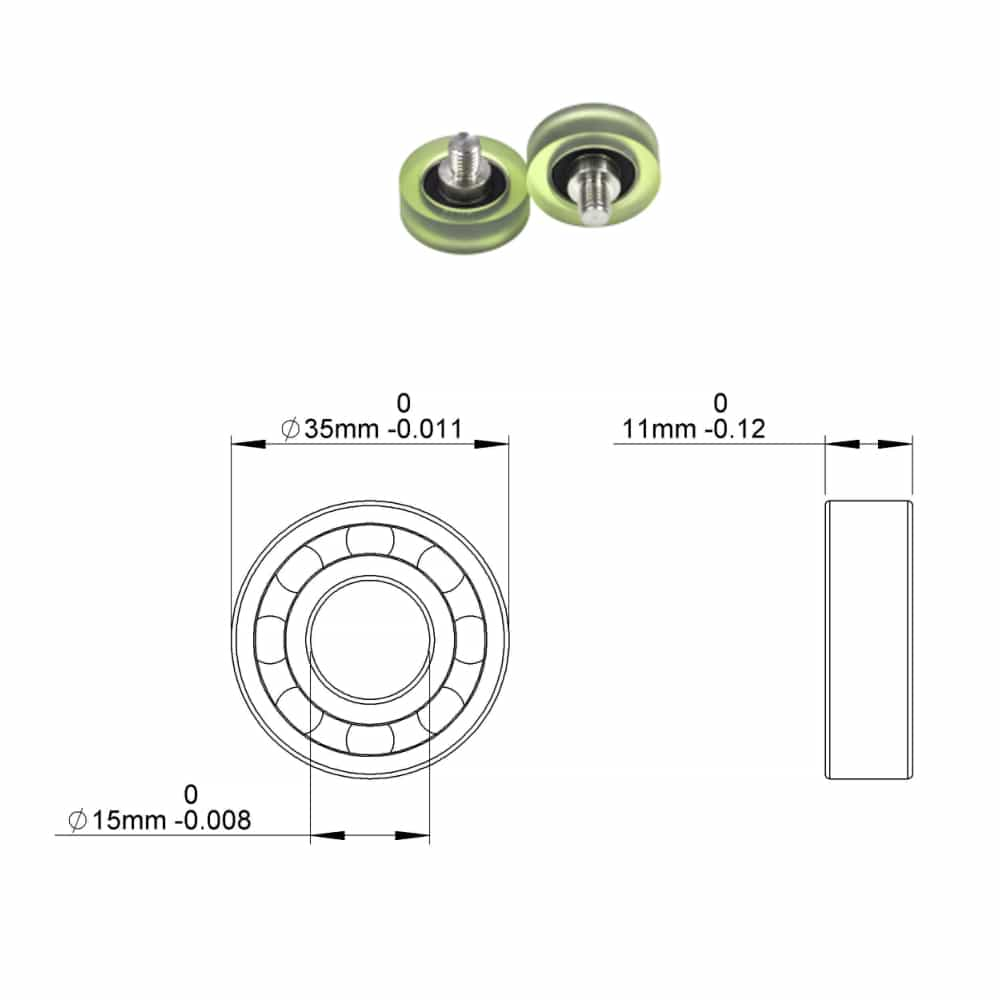

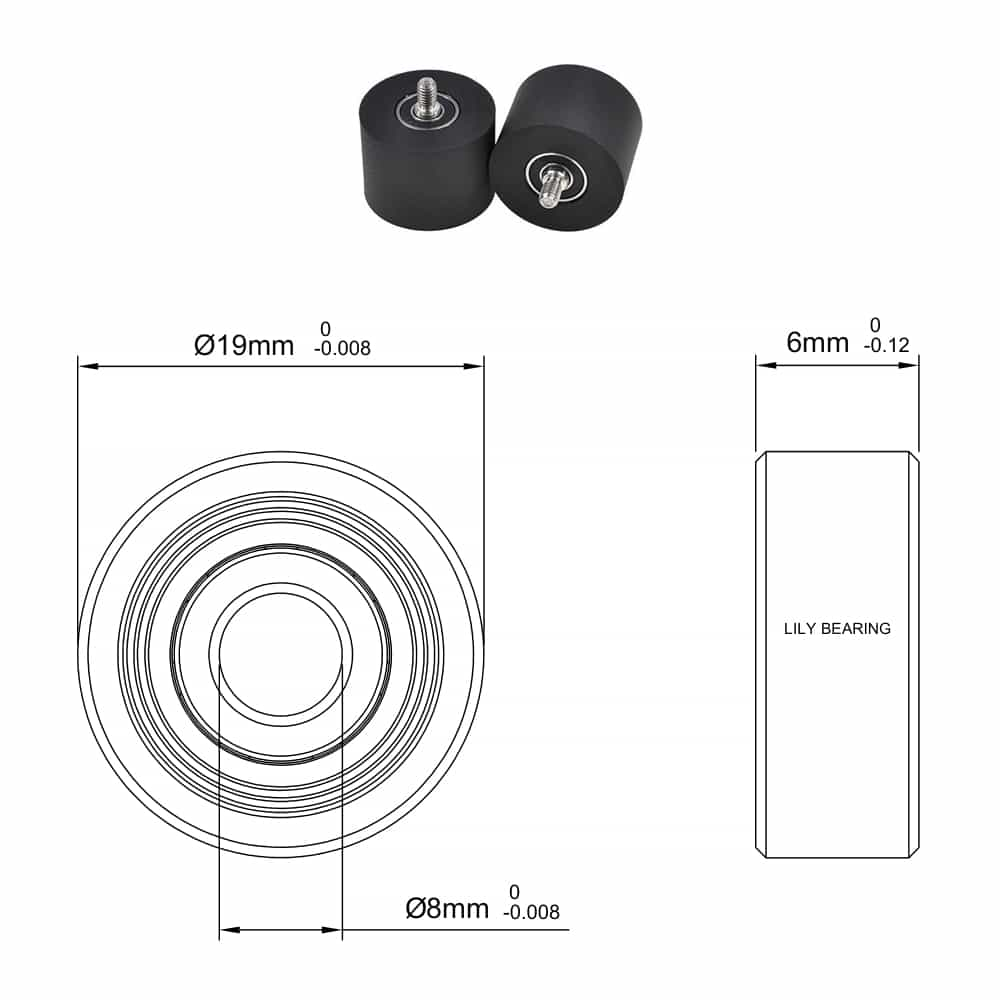

Polyurethane Coated Bearing With Screw

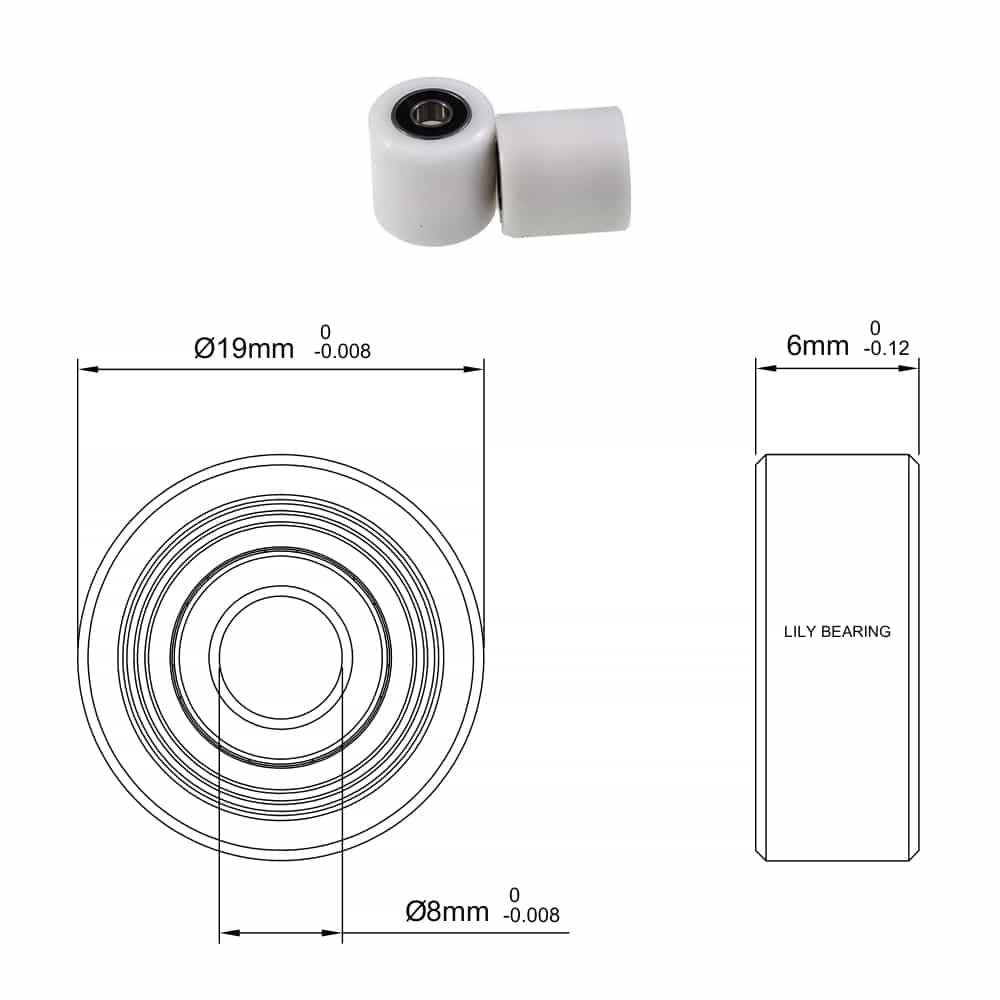

Polyurethane Coated Cam Followers/Track Rollers

We also provide outsourcing options, such as:

Outsourcing Polyurethane bearings

Outsourcing Polyurethane Coated Bearing With Screw

Importance of Food-Grade Materials

In the food industry, materials must meet strict safety standards to prevent dirt and ensure food safety. A material is deemed food-grade if it is non-toxic, non-reactive, and safe for food contact under all processing conditions. Regulatory bodies like the FDA in the U.S. and the EU set these standards to protect consumers.

Advantages of Polyurethane Rollers in the Food Industry

Polyurethane rollers have several key advantages, making them a top choice for food processing. Below, we explain how these benefits improve performance, safety, and efficiency in the food industry.

Safety and Hygiene

Food-grade polyurethane rollers are specifically designed to meet the highest food safety standards. They are non-toxic and non-reactive, ensuring that no harmful substances are transferred to food products during processing. Additionally, their smooth surface reduces the risk of bacterial growth, making them an ideal choice for maintaining hygiene in food production environments.

Durability and Longevity

Polyurethane rollers are known for their long-lasting durability. They can endure the tough conditions often found in food processing, such as high temperatures and strong cleaning chemicals. This durability means fewer replacements, lower maintenance costs, and less downtime.

Resistance to Chemicals and Moisture

Chemical Resistance: In food processing, rollers often deal with chemicals like cleaning agents and food-grade lubricants. Polyurethane rollers are highly resistant to these chemicals, so they stay durable and effective. Their moisture resistance also helps them last longer in wet or humid conditions.

Non-Stick and Easy to Clean

Reducing Friction and Wear: Polyurethane's non-stick surface is a key advantage. In the food industry, this helps prevent product buildup on equipment. Polyurethane rollers are also easy to clean and sanitize, which reduces the risk of contamination and makes them ideal for food-related applications.

Applications of Polyurethane Rollers in the Food Industry

Conveyor Systems

Conveyor Rollers: Polyurethane rollers are essential in conveyor systems within food processing plants. They ensure the smooth and efficient movement of food products along the conveyor belt.

- These rollers help transport items from one processing stage to the next without causing damage.

- They maintain product integrity by preventing contamination throughout the process.

Packaging Machines

In food packaging, polyurethane rollers are essential for keeping products safe and intact. They facilitate the smooth and precise handling of food items during the packaging process, ensuring that each product is securely and hygienically enclosed.

- These rollers help prevent damage to the food, such as crushing or deforming, which can occur with less resilient materials.

- By maintaining consistent pressure and alignment, polyurethane rollers contribute to the efficient sealing of packages. This is crucial for preserving the freshness and safety of the food. This meticulous packaging process can ensure that the food reaches consumers in optimal condition, free from contamination and spoilage.

Processing Equipment

Urethane rollers are crucial parts of many food processing machines, like dough mixers, meat grinders, and vegetable peelers.

- They are designed to handle the heavy-duty tasks these machines perform every day, keeping operations smooth and reliable.

- Their durability helps them withstand constant use, making them perfect for the tough conditions in food processing.

- These rollers keep machines running efficiently, ensuring that food products are processed without any disruptions.

Compliance and Standards for Food-Grade Polyurethane Rollers

FDA Compliance

The FDA sets strict standards for materials that come into contact with food. Food-grade polyurethane rollers comply with these standards, ensuring that they are safe for use in all food processing applications. This compliance guarantees that the rollers do not release any harmful substances into food products, protecting consumer health.

EU Regulations

- The European Union has set regulations for food-grade materials to ensure safety in the food industry.

- Polyurethane rollers that meet EU standards are certified as safe for use in food processing, packaging, and handling.

- This makes them a dependable choice for manufacturers across Europe.

Case Studies

Bakery Industry

In a bakery, polyurethane rollers are essential in dough processing machines. These rollers are highly durable, which reduces the frequency of replacements.

The bakery saw less downtime and fewer maintenance issues after switching to polyurethane rollers. This change led to better product quality and more efficient operations overall.

Meat Processing Plant

Polyurethane rollers are widely used in meat processing plants for handling products like sausages and patties.

One plant saw significant benefits after switching to these rollers, including better safety and hygiene standards. The use of polyurethane rollers also reduced contamination risks and increased processing speed and efficiency.

Choosing the Right Polyurethane Rollers for Your Food Industry Needs

Factors to Consider

When selecting polyurethane rollers for food processing, consider these key factors:

- Load Capacity: Ensure the rollers can support the weight of the products and equipment to prevent wear and maintain consistent performance.

- Temperature Resistance: Choose rollers that can withstand extreme temperatures in your processing environment without degrading.

- Chemical Resistance: Opt for rollers that can resist exposure to cleaning agents and chemicals to maintain safety and durability.

- Surface Properties: Select rollers with non-stick surfaces that are easy to clean, reducing contamination risks and simplifying maintenance.

- Food-Grade Compliance: Ensure the rollers meet FDA or EU standards to guarantee they are safe for food processing.

Customization Options

Polyurethane rollers can be customized to meet the unique needs of your production line. By working with a reliable supplier, you can get rollers designed to match your exact requirements, such as the right hardness, size, and design. This ensures the rollers perform optimally in your application.

Maintenance and Care for Polyurethane Rollers

Proper maintenance is key to keeping polyurethane rollers in top condition. Regular care helps spot issues early. This extends the life of the rollers and ensures smooth operation with less downtime.

Regular Inspection

To maintain optimal performance, it’s crucial to regularly inspect polyurethane rollers for signs of wear and tear. Look for issues such as surface degradation, cracks, or changes in roller shape that might indicate the need for replacement or maintenance.

Cleaning and Sanitization

To keep polyurethane rollers in good condition, proper cleaning and sanitization are essential. Use recommended cleaning agents and methods to ensure they remain free from contaminants. This will keep them safe for food processing.

Conclusion

Food-grade polyurethane rollers are vital in the food industry. They can offer unmatched safety, durability, and efficiency compared to other materials. Choosing the right rollers can boost your production line's performance, lower maintenance costs, and ensure top food safety standards. For expert advice and high-quality rollers, contact us today to find the best solution for your food processing needs.

Keep Learning