Sign in

New customer? Start here

How Ceramic Bearings Improve Skateboard Performance

CONTENTS

- What Are Ceramic Bearings?

- Advantages of Ceramic Bearings for Skateboarding

- How Ceramic Bearings Improve Skateboard Performance in Various Scenarios

- Ceramic Bearings vs. Steel Bearings: A Detailed Comparison

- Real-World Feedback: Are Ceramic Bearings Worth It for All Skaters?

- How to Care for Ceramic Bearings for Optimal Performance

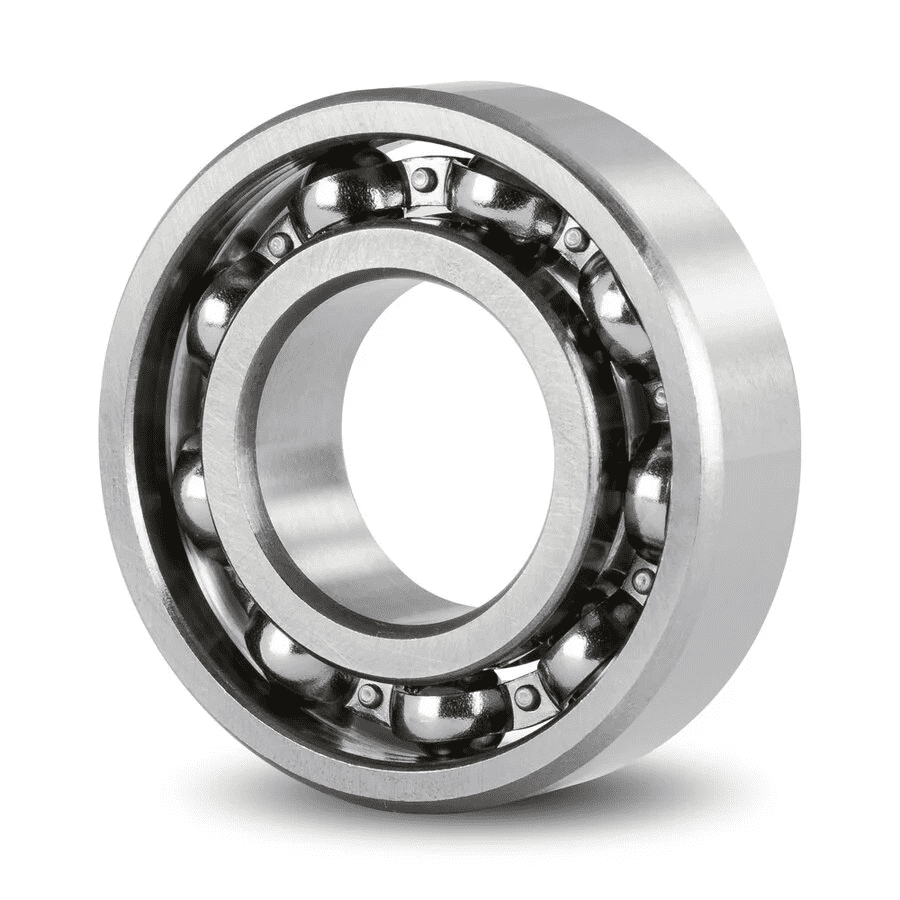

What Are Skateboard Bearings?

Skateboard bearings are specially designed parts that help the wheels of a skateboard spin smoothly around the axle. Bearings allow skateboard wheels to spin effortlessly. They reduce friction between the wheel and the axle. This makes it easier to maintain speed with less effort. Skateboard bearings can impact the skateboard's performance, speed, and durability.

Why Bearings Matter in Skateboarding?

Bearings play a crucial role in skateboarding for several reasons:

- Speed: High-quality skate bearings cut down friction between the skateboard wheels and axle, helping skateboarders go faster with less effort.

- Smoothness: Smooth-rolling bearings contribute to a fluid ride. Well-maintained bearings make skateboarding smoother, helping you ride over different surfaces and perform tricks more easily.

- Overall Riding Experience: Good bearings help skateboarders have better control and feel more in tune with their board. They make it easier to respond to movements, improving the overall ride.

What Are Ceramic Bearings?

Ceramic Bearings vs. Steel Bearings:

- Ceramic Bearings: Ceramic ball bearings are made from lightweight materials like silicon nitride or zirconium dioxide. They possess high strength and are resistant to rusting.

- Steel Bearings: Steel bearings are usually made from strong and durable high-carbon steel. Some may have a coating to help prevent rust, but they can still rust more easily than ceramic bearings.

Types of ceramic bearings:

- Full Ceramic Bearings:

These bearings are made entirely from ceramic materials, including both the balls and the races.

Benefits: Full ceramic bearings are light, resist rust, and can handle high temperatures.

These bearings feature ceramic balls but have steel races (the outer and inner rings).

Benefits: The ceramic balls help reduce friction and weight, while the steel races add strength and durability. They usually cost less than full ceramic bearings but still perform well.

How Ceramic Bearings Work

Ceramic bearings use smooth ceramic balls to reduce friction, making movement faster and smoother. They are lightweight, resist rust, handle heat well, and need less maintenance than steel bearings.

Advantages of Ceramic Bearings for Skateboarding

Enhanced Durability and Longer Lifespan

ceramic skate bearings are better at resisting rust and corrosion than steel bearings. They are also less likely to deform, which helps them last longer, especially in tough conditions like rain or street skating.

Reduced Friction and Faster Rolling

Ceramic balls produce less friction because they have a smoother surface and a lower coefficient of friction. This leads to higher RPM (rotations per minute) and improved performance at high speeds.

Heat Resistance and Stability

Ceramic bearings can handle high temperatures without changing shape. This allows them to maintain steady performance, even when carrying heavy loads or riding down long hills.

Lighter Weight for Faster Acceleration

Ceramic balls possess a lower weight compared to steel balls. This reduces the weight that needs to be moved, allowing for quicker acceleration and better responsiveness.

How Ceramic Bearings Improve Skateboard Performance in Various Scenarios

Speed and Smoother Rides

For downhill riders and speed lovers, ceramic bearings roll faster and keep speed over long distances.

Durability in Harsh Conditions

Street skaters benefit from ceramic bearings because they resist corrosion and dirt. This makes them a better choice for skating in wet or dusty environments.

Competitive Edge for Park and Pool Skaters

Park and pool skaters enjoy smoother transitions and grinding with ceramic bearings. This is because they have less drag and provide better rotational consistency.

Ceramic Bearings vs. Steel Bearings: A Detailed Comparison

Speed and Friction

- Rolling Resistance:

Steel Bearings: They have more rolling resistance because of their rougher surfaces. This increases the friction between the steel balls and the races.

Ceramic Bearings: They have less rolling resistance because their surfaces are smoother and made from better materials.

- Friction:

Steel Bearings: They create more friction when they operate, which can cause more wear and tear over time.

Ceramic Bearings: They create much less friction because of their smooth surfaces and lower friction levels.

Differences in speed and RPM between steel and ceramic bearings during performance:

- Speed:

Steel Bearings: The rougher surface of steel and the extra contact between parts lead to more energy loss. This reduces the overall speed.

Ceramic Bearings: With less resistance, Ceramic bearings can keep higher speeds more easily, especially in high-performance situations.

- RPM (Rotations Per Minute):

Steel Bearings: Steel bearings tend to have lower RPM limits because of the heat and friction they generate during use.

Ceramic Bearings: Ceramic bearings can achieve higher RPMs because of their lower coefficient of friction and better heat resistance.

Maintenance and Longevity

- Ceramic bearings are more durable and need less maintenance because they resist rust and wear. Regular cleaning is important to keep them performing well. They also need less lubrication because they create less friction.

- Steel bearings require more regular maintenance to prevent rust and corrosion, especially when exposed to moisture. Steel bearings require more frequent lubrication, reducing friction and wear during use.

Cost and Value

Ceramic bearings typically cost more than steel bearings because they are made with special materials and advanced methods. Although they are more expensive upfront, many skaters believe they are worth the investment. Their longer lifespan means they last longer than steel bearings. Additionally, lower maintenance requirements can save skaters money over time.

For most skateboarders, especially those who skate often or challengingly, ceramic bearings are a good investment. They last longer, require less maintenance, and offer better performance.

Real-World Feedback: Are Ceramic Bearings Worth It for All Skaters?

Pros and Cons from Skater Perspectives

|

Perspective |

Pros |

Cons |

|

Skater Perspectives |

- Help skaters go faster with less effort, ideal for downhill skating and racing. |

- Higher cost compared to steel bearings, which can be an issue for casual skaters. |

Situations Where Ceramic Bearings Shine

Ceramic bearings are great for high-speed activities like downhill skating and longboarding, especially in wet conditions.

Casual skaters usually don't experience the same benefits from ceramic bearings as competitive skaters. This is because they skate at lower speeds and in easier conditions. For casual skaters, the higher price of ceramic bearings might not be worth it, so steel bearings are often a better choice.

How to Care for Ceramic Bearings for Optimal Performance

Cleaning and Lubrication Tips

Maintenance Tips:

- Keep Bearings Clean

- Lubricate Regularly

- Inspect for Wear

- Handle with Care

- Avoid Overloading

- Monitor Heat

Myth-Busting:

- Myth: Ceramic Bearings Don’t Need Lubrication:

Fact: They still need lubrication to prevent wear.

- Myth: You Can Clean Them with Water:

Fact: Water can cause corrosion or leave deposits. Use an appropriate cleaning agent.

- Myth: Ceramic Bearings Don’t Need Maintenance:

Fact: All bearings, even ceramic, need regular care to last longer.

- Myth: Ceramic Bearings Can’t Get Dirty:

Fact: They are still vulnerable to dirt and debris, so keep them clean.

Increasing Lifespan Through Proper Use

To make ceramic bearings last longer, always lubricate them to reduce wear. Ensure they are cleaned thoroughly and avoid exceeding their weight capacity. Also, install them correctly and keep an eye on temperatures to avoid damage.

To keep ceramic bearings working well, clean them with the right solvents to remove dirt. Handle them carefully during installation to avoid damage. This helps them stay strong, reduce friction, and last longer.

Conclusion

Ceramic bearings offer lower friction, resist rust, handle high heat, and need less maintenance, which helps them last longer. Industries like aerospace, automotive, and high-speed machinery benefit the most from these features. Upgrading to ceramic bearings can improve skateboard performance, especially for those who prioritize speed and durability.

FAQs About Ceramic Bearings for Skateboarding

Are ceramic bearings faster than steel bearings?

Yes, ceramic bearings are usually faster than steel bearings because they have lower friction and smoother surfaces.

Do ceramic bearings require special maintenance?

Ceramic bearings don’t require special maintenance, but they do benefit from regular care.

What’s the lifespan of ceramic bearings compared to regular bearings?

Ceramic bearings have a longer lifespan than regular steel bearings.

Can beginner skateboarders benefit from ceramic bearings?

For beginners learning basic skills, standard bearings are often a better choice. As they improve and focus on performance, ceramic bearings can be a good upgrade.

Keep Learning