Sign in

New customer? Start here

How Does a One Way Bearing Work?

A one way bearing is an important component in many machines, designed for specific tasks. It is vital in applications where controlled movement is required. In this blog, we'll dive into "How Does a One Way Bearing Work" and explore its construction and importance in various industries.

What Is a One Way Bearing?

A one way bearing, also known as a freewheel or overrunning clutch, is a mechanical device that allows rotation in only one direction.

One way bearings come in various designs, including those that use needle rollers. When a one way bearing uses needle rollers, it's often referred to as a one way needle roller bearing or one way needle bearing. This blog specifically discusses this type of one way bearing.

Construction and Design

- Needle Rollers: The core of a one way needle roller bearing clutch is made up of needle rollers, which are thin cylindrical rollers. These rollers are arranged parallel to the axis of the bearing and provide a large contact area, distributing the load evenly.

- Inner and Outer Rings: The bearing consists of an inner ring (or shaft) and an outer ring (or housing). The needle rollers are situated between these two rings. The outer ring typically houses the needle rollers, which rotate along the inner ring.

- Cam or Ramp Design: This design is what allows the bearing to lock in one direction and freewheel in the other. When rotation is in the allowed direction, the rollers move freely along the cam surfaces. When rotation is attempted in the opposite direction, the rollers are forced against the cam, causing them to lock and prevent motion.

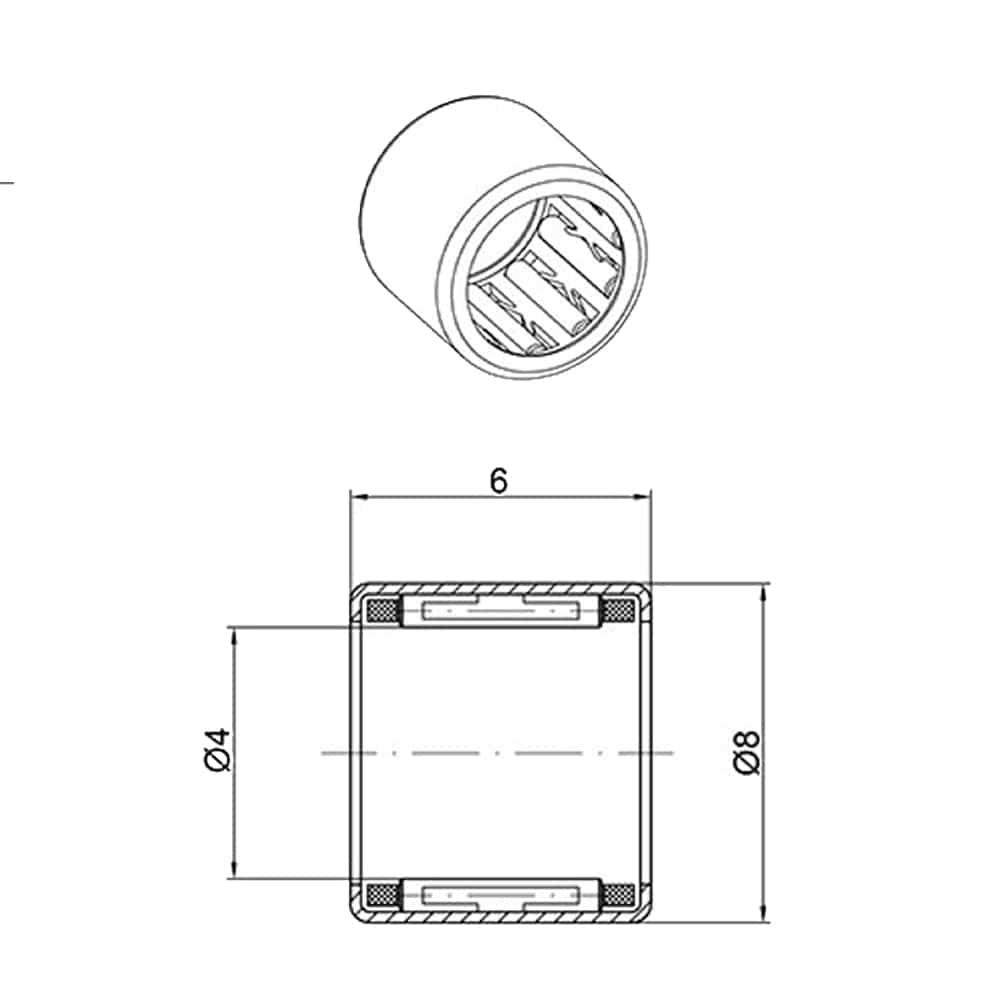

Structure of a One Way Bearing (Single Row)

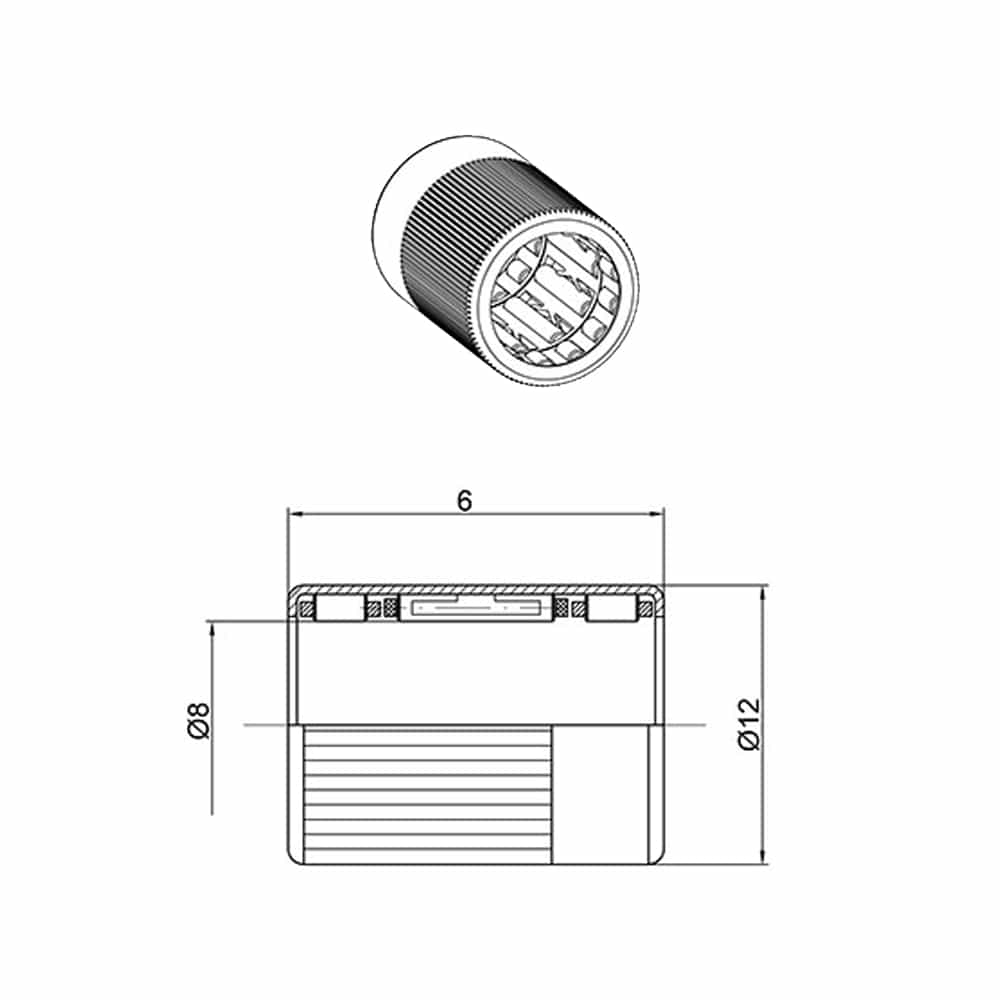

Structure of a One Way Bearing (Triple Row)

Purpose in Mechanical Systems

- Smooth Operation: One way bearings ensure smooth and controlled movement by allowing rotation in only one direction.

- Damage Prevention: They prevent reverse rotation. This helps protect the system from damage.

Explore How a One Way Bearing Works

Let's analyze from the following three aspects:

Torque Transmission

- Smooth Rotation: In the permitted direction of rotation, the needle rollers inside the bearing move smoothly along the cam surfaces. This movement is unhindered, with minimal friction, allowing the inner ring (or shaft) and outer ring (or housing) to rotate freely relative to each other.

- Torque Flow: This free movement enables the efficient transmission of torque from one component to another. In applications such as conveyor belts, this means that the belt can move forward without resistance, driven by the motor. In starter motors, it allows the engine to crank smoothly in the intended direction, facilitating a quick start.

- Control and Precision: The design allows for precise control of movement. This is important for applications that need consistent torque transmission to keep things running efficiently and safely.

Locking Mechanism:

- Opposite Direction Resistance: When rotational force is applied in the opposite direction, the situation changes dramatically. The needle rollers, which previously moved freely, are now pushed against the cam surfaces inside the bearing.

- Wedging Effect: This contact between the rollers and the cam surfaces creates a wedging effect. The rollers become tightly wedged between the inner and outer rings, effectively locking them together.

- Preventing Reverse Motion: This locking action is what stops any reverse rotation. In practical terms, this means that in applications like conveyor systems, the belt cannot slip backward, and in starter motors, the engine components do not move in the wrong direction, protecting the system from damage and ensuring smooth operation.

Engagement and Disengagement

- Automatic Engagement: The bearing engages automatically when force is applied in the locking direction. The needle rollers quickly lock the inner and outer rings together as soon as reverse motion is attempted. This provides immediate resistance and prevents unwanted movement.

- Automatic Disengagement: Conversely, when the force is removed or the direction of rotation is returned to the allowed direction, the bearing disengages. The needle rollers move away from the cam surfaces, freeing the inner and outer rings to rotate independently again.

These bearings automatically engage and disengage, which is vital for systems needing quick and reliable responses. In industrial machinery, where processes must start or stop instantly, this feature ensures the bearings respond correctly to changes in load or direction. This helps the system run smoothly and efficiently.

What Are One Way Bearings Used For?

A one way bearing is often used in conveyor systems, starter motors, and other machines that need precise control of direction.

- Conveyor Systems: In conveyor belts, these bearings prevent backward movement. This ensures that materials move smoothly in the intended direction without slipping.

- Starter Motors: In automotive applications, one way needle-roller bearing clutches are used in starter motors. They engage the engine quickly and disengage just as fast. This allows the vehicle to start smoothly without any backward movement of engine components.

- Industrial Machinery: These bearings are crucial in industrial machines that need precise control of rotational direction. They are used in printing presses, textile machines, and packaging equipment. This precision helps the machines run smoothly and accurately.

What Does a One Way Bearing Provide?

The one way bearing offers several key benefits that make them essential in many mechanical systems:

High Load Capacity

- Bearing Load Distribution: Needle rollers distribute the load over a larger area. This reduces stress and allows the bearing to handle heavier loads effectively.

- Consistent Torque: These bearings ensure smooth torque transmission, even with heavy loads. This makes them reliable for critical uses like conveyors and starter motors.

Compact Design

- Space Eficiency: Their compact size makes them ideal for use in tight spaces, such as automotive transmissions and industrial machines.

- High Performance: Although they are compact, these bearings offer strong performance and handle high loads effectively. They maintain durability despite their small size.

Reliability and Durability

- Consistent Operation: The locking mechanism is highly reliable and it ensures precise engagement and disengagement.

- Long Lifespan: Made from durable materials like hardened steel, these bearings resist wear and offer long service life, reducing the need for frequent replacements.

Low Maintenance

- Reduced Lubrication Needs: They require less lubrication compared to other bearings, which reduces maintenance needs.

- Easy Maintenance: When service is needed, their simple design makes maintenance quick and straightforward, leading to less downtime.

Quick Response

- Instant Engagement: These bearings engage and disengage rapidly, which is crucial in applications where quick directional changes are common.

- Safety: Their fast response helps prevent mechanical failures and enhances system safety.

Maintenance and Care

- Bearing Lubrication: Regular lubrication is crucial for the smooth operation of one way needle roller bearing clutches. It helps reduce friction, prevents wear, and extends the lifespan of the bearings.

- Routine Checks and Replacement: Routine inspection is necessary to detect signs of wear or damage. Replacing worn-out bearings promptly can prevent failures and ensure the continued reliability of the system.

- Cleaning: Keeping the bearings clean and free from contaminants is crucial, especially in environments where dust or debris may be present. Regular cleaning prevents buildup that could interfere with the bearing’s operation.

Conclusion

one way bearings are essential for smooth, controlled movement in mechanical systems. Knowing how they work helps you select the right bearing for optimal performance and reliability.

For expert guidance and top-quality one way bearings, contact us today. We’re here to help you find the best solution for your needs.

Keep Learning