Sign in

New customer? Start here

How to Properly Install McGill Cam Followers

McGill cam followers are important parts that help machines move precisely and reliably. They convert rotational motion into linear motion. Their proper installation is key to making sure they last and work well.

Tools and Materials Needed

Required Tools

To ensure the successful completion of the task, the following tools and materials are recommended:

- A variety of wrenches are necessary, including open-end, ring, or torque wrenches, to facilitate the work process.

- Appropriate lubrication tailored to your specific requirements should be utilized.

- A bearing press may be required for certain installations; it is advisable to have one on hand.

- While not mandatory, a soft-faced hammer can be a useful addition to your toolkit.

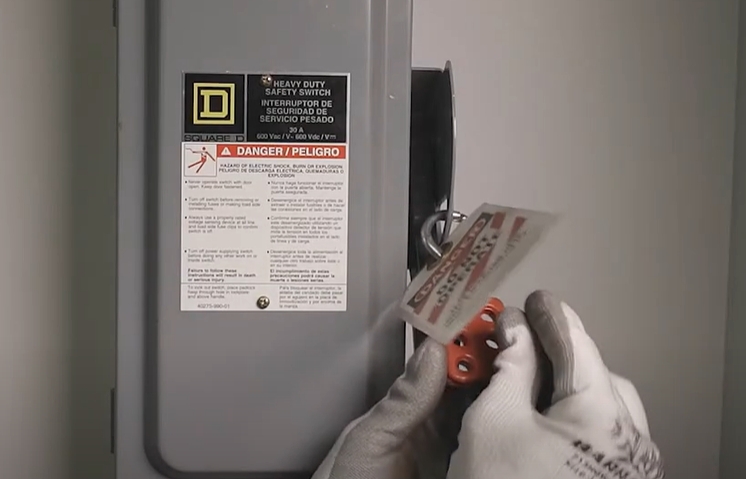

Safety Equipment

Staying safe is always the priority when you're working. Make sure you have these things to keep you protected:

- Gloves to protect your hands.

- Ensure the use of safety glasses for eyes protection.

- Employ hearing protection when operating loud machinery.

- Wear work attire that covers the arms and legs.

Step-by-Step Installation Guide

Step 1: Preparation

Before installation, inspect the housing and bearing first

- Clean the Housing: Thoroughly clean the area to remove any dirt, burrs, or sharp edges that could harm the bearing.

- Check the Fit: Make sure the bore diameter of the housing matches the bearing specifications, so that there will be a secure, snug fit between the bearing stud and housing.

Step 2: Align the Cam Follower

Proper Positioning

Position the cam follower accurately over the mounting hole to ensure proper fit and function.

- For Stud Cam Followers: Use a bearing press to insert the stud into the housing. Apply force directly to the stud, not the roller, to prevent damage.

- For Yoke Cam Followers: Make sure the shaft fits properly to maintain alignment and avoid any misalignment issues while the machine is running.

Blind Hole and Eccentric Bushing Mounting

- For Blind Hole Mountings: Ensure that your cam follower is securely seated in the hole to prevent it from slipping or becoming misaligned.

- For Eccentric Bushings: Follow the maker's instructions carefully when you put them in. This way, you can be sure they'll sit right and function as intended.

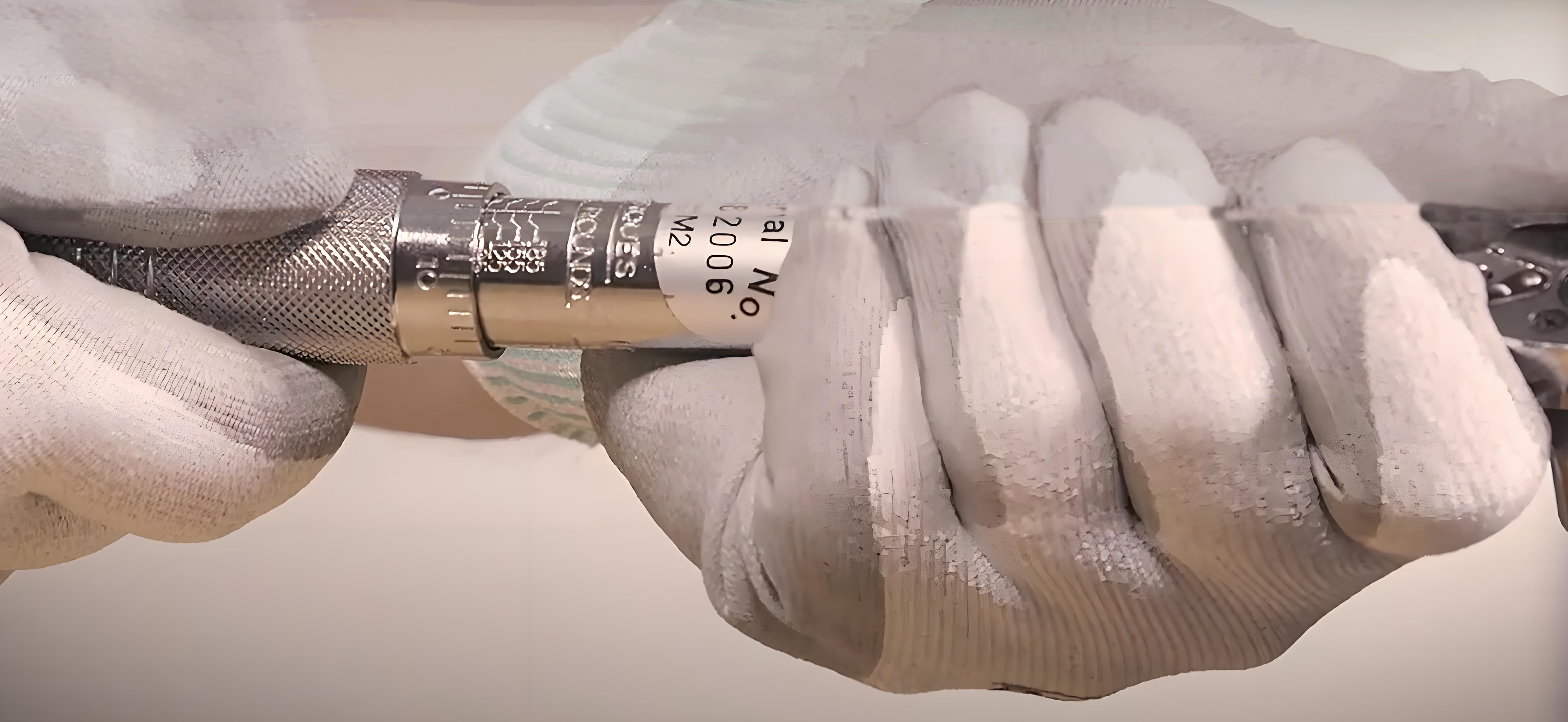

Step 3: Fastening the Cam Follower

Use Recommended Torque Values

When securing a cam follower, always follow the recommended torque values listed in torque tables. These values change depending on the cam follower model and size, like CF, CFH, or MCF. In this way you can tighten the cam follower properly to secure it correctly and to prevent any damage. Use a locknut or jam nut according to manufacturers’ recommendations to prevent the stud from loosening because of overstress.

Use of Locking Mechanisms

Some studs feature a screwdriver slot or hexagonal hole, which serves as a locking mechanism. When using these, be cautious not to apply excessive force that could strip the threads or bend the stud. Always follow the maker’s guidelines for secure and reliable fastening.

Step 4: Verify Installation

After installing the cam followers, perform a test to ensure they glide freely and smoothly without any obstruction. After installing the cam followers, conduct a trial operation to verify that they move freely and smoothly without any obstruction. This is crucial for smooth movement.

Next, perform a load test by applying a small load to confirm the follower operates smoothly under normal conditions. This check makes sure your cam follower is good to go for real work and stops any problems from happening later.

Common Installation Mistakes and Solutions

Over-Tightening or Under-Tightening

Over-tightening or under-tightening cam followers can have detrimental effects. Over-tightening can stretch the stud, causing it to loosen over time and break. This can lead to reduced performance and even machinery downtime. On the other hand, under-tightening may may result in its detachment or improper functioning.

To prevent such problems, consistently check and apply the torque values as the manufacturer recommend. You can find these values in the torque charts designed for the particular cam follower model and dimensions. This ensures optimal fastening and extend the service life of the cam follower.

Incorrect Alignment

Cam followers that are misaligned can cause uneven operation, which increases stress and may lead to the bearings failing sooner than expected.

Best Practices for Prevention:

- Use special tools like laser alignment systems or dial indicators to make sure the correct alignment is maintained.

- Routinely inspect your McGill cam followers so that they remain in excellent working state. This way, you can spot and fix any misalignment before it causes serious problems.

Proper Alignment:

Make sure that cam followers, like Flange Yoke types, are set up correctly to handle the right amounts of axial and radial loads as per the manufacturer's guidelines.

Maintenance Tips

Lubrication

Keep your McGill cam followers running smoothly and lasting longer with the right lubrication.

Lubricant Selection:

Listen to what the maker says about which lubricant to use and how often to use it. Consider the machine's usage and its location.

Lubrication Application:

Apply lubricant to the right spots, like the radial lubrication hole, positioned where it's most effective in the raceway.

Maintenance for Yoke Cam Followers:

Keep up with your regular maintenance plan. Yoke Cam Followers may require frequent lubrication, so remember to keep an eye on them.

Preventive Measures:

Regular lubrication reduces friction, prevents wear, and keeps your cam followers going strong for longer.

Periodic Inspection

General Inspection:

- Regularly look for signs of wear that could affect the McGill Cam follower's performance.

- Make sure that all locking mechanisms are secure to prevent any loosening during operation.

V-Groove and Flange Stud Specifics:

- For V-Groove and Flange Stud Cam Followers, ensure they are correctly engaged with their tracks.

- Proper engagement is crucial for smooth operation and to prevent premature wear or failure.

Conclusion

Following each installation step precisely is crucial for the longevity and performance of your McGill cam followers. Adhering to torque values and maintenance schedules will extend the life of your cam followers. Remember, LILY Bearing provides high-quality equivalents to McGill cam followers, offering reliable alternatives for your industrial needs.

Keep Learning