Slewing Bearing: Kaydon VS LILY Bearing

Slewing bearings, also known as slewing rings or turntables bearings, facilitate rotational movement while supporting heavy loads. They are essential in various applications like cranes, wind turbines, and excavators.

Kaydon and LILY are renowned manufacturers of slewing bearings. In this article, a comparison has been made between Kaydon and LILY regarding single row four-point-contact slewing bearings MTE-210T, with dimensions of ∅8.268 x ∅14.686 x1.575 inches.

The comparative analysis reveals differences in MTE-210T’s raw material, heat treatment, grease, size, rotation accuracy and static load. Understanding these differences can help users select the most suitable slew bearings for their specific needs.

Raw Material Comparison

l Inner & Outer Ring

Table 1 Inner & Outer Ring Raw Material Comparison

|

Attribute/Brand |

KAYDON |

LILY |

|

Original Material |

50Mn |

42CrMoA |

|

Recommended Material |

C45 E tempered steel, or 42C2 steel/46Cr2 |

42CrMo (equivalent to 42CrMo4 (1.7225)) |

|

Chemical Composition |

C: 0.52-0.54% Si: 0.20-0.21% Mn: 1.51-1.61% Ni: 0.024-0.031% P: 0.0132-0.0135% S: 0.0077-0.0087% Cr: 0.24-0.25% Cu: 0.042% |

C: 0.38-0.45% Si: 0.17-0.37% Mn: 0.50-0.80% P: ≤0.030% S: ≤0.030% Cr: 0.90-1.20% Mo: 0.15-0.25% |

|

Mechanical Properties |

Tensile Strength: 975 MPa Elongation: 17.5%

|

Yield strength: ≥930 MPa Tensile Strength: ≥1080 MPa Elongation: ≥12% Hardness: ≤217 HB |

|

Material Substitution |

No local substitution materials |

42CrMo-GB/T 3077instead of 50Mn |

l Balls

Table 2 Balls Raw Material Comparison

|

Attribute/Brand |

KAYDON |

LILY |

|

Material Specification |

100Cr6 EN ISO 683-17:2000 |

GCr15-GB/T 18254 |

|

Chemical Composition |

C:0.99%, Si:0.28%, Mn:0.30%, P:0.0093%, S:0.0055%, Cr:1.49%, Ni:0.017 Mo:0.006, Ti: ≤0.0007%; Al:0.0073%; Cu: 0.018%

|

C:0.95-1.05%, Cu:≤0.25%, Si:0.15-0.35%, O:≤0.0012%, Mn:0.25-0.45%, Ti:≤0.005%, P:≤0.025%, Al:≤0.05%, S:≤0.02%, As:≤0.04%, Cr:≤1.40-1.65%, As+Sn+Sb:≤0.075%, Ni:≤0.25%, Pb:≤0.002%, Mo:≤0.10% |

|

Mechanical Properties |

Yield strength: ≥590 MPa, Tensile Strength: ≥830-1130 MPa, Elongation: ≥10%, Diameter: 30 mm, Annealed to achieve spheroidized carbides: ≤207HBW, Annealed and cold worked: ≤241HBW |

Yield strength: ≥518.42 MPa, Tensile Strength: ≥861.3 MPa, Elongation: ≥27.95%, Spheroidizing annealing hardness: 179-207 HBW, Softening annealing hardness: ≤245 HBW |

Since the GCr15 material of the LILY brand is considered an equivalent material to the 100Cr6 of the KAYDON brand in the market, there will be similarities in mechanical properties and chemical composition. However, the specific heat treatment processes and hardness requirements may differ, which could affect the performance and overall durability of the balls and the bearing.

Heat Treatment Comparison

l Inner & Outer Ring

Table 3 Inner & Outer Ring Heat Treatment Comparison

|

Heat Treatment Attribute/Part/Brand |

KAYDON |

LILY |

|

Inner & Outer Ring Heat Treatment |

Outer ring substrate(HRC):32.2-33.5 Inner ring substrate(HRC):34-34.5 |

Heat treated to HRC 30-35 for Lily bearing's inner & outer rings body before final machining. |

|

Inner & Outer Raceway Heat Treatment |

Standard hardened layer depth of 3.5 mm. Outer ring raceway(HRC):61-62.5

|

Selective hardening, inner raceway surface hardness of HRC57-62, with a case depth of ≥2.5 mm. |

|

Heat Treatment Markings |

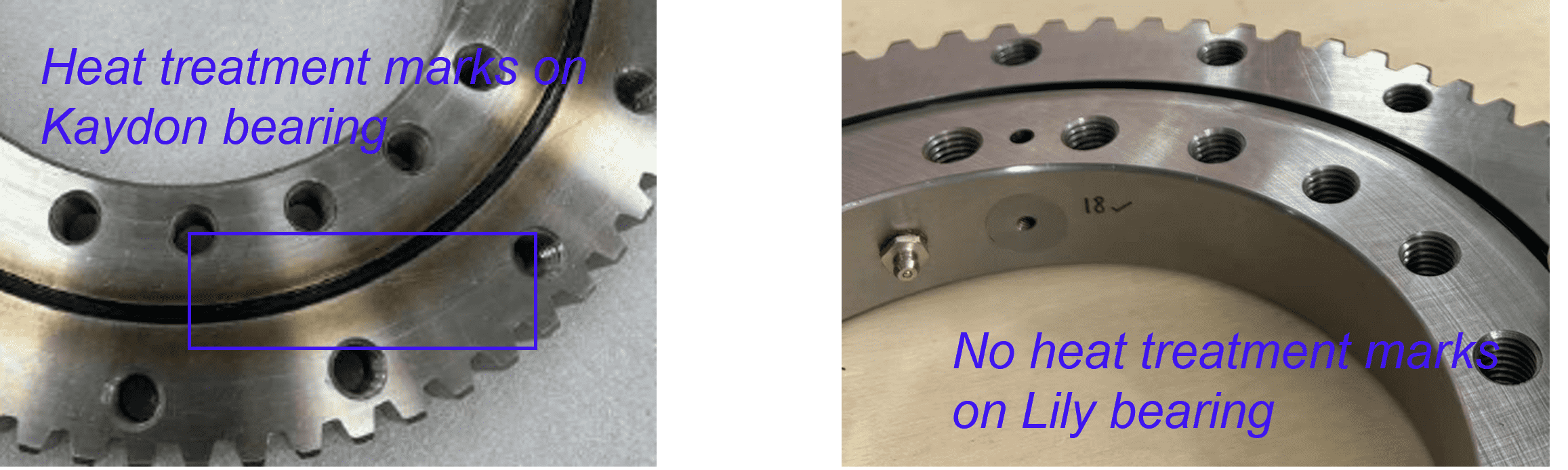

Kaydon bearings have post heat treatment markings. |

Heat treatment marks are removed after final surface grinding for Lily bearing's raceways. |

|

Hardness Requirement |

Outer ring substrate(HRC): ≤23.1 Outer ring raceway(HRC):55-60 Inner ring substrate(HRC):21-27.8 Depth of standard hardened layer ≥2 mm |

HRC 18-21 for both inner and outer rings. |

|

Impact of Heat Treatment |

No specific impact of heat treatment on bearing performance specified. |

Little deformation observed after over a year of operation, indicating that the current hardness has minimal impact on the bearing's function. |

Table 4 Kaydon vs Lily Bearing in Surface Hardness

| LILY HRC | Kaydon HRC | |||||||

| Bearing Structure | Location | HRC | Bearing Structure | Location | M140 | M134 | M138 | |

| Inner Ring | Edge | 32 | Inner Ring | Edge | 30 | 33 | 32 | |

| 34 | 31 | 32 | 32 | |||||

| 34 | 31 | 31 | 31 | |||||

| Center | 32 | Center | 31 | 34 | 32 | |||

| 32 | 31 | 32 | 34 | |||||

| 33 | 31 | 33 | 33 | |||||

| Outer Ring | Edge | 31 | Outer Ring | Edge | 34 | 35 | 35 | |

| 32 | 34 | 35 | 35 | |||||

| 31 | 33 | 35 | 36 | |||||

| Center | 32 | Center | 32 | 34 | 33 | |||

| 31 | 33 | 33 | 33 | |||||

| 33 | 32 | 34 | 34 | |||||

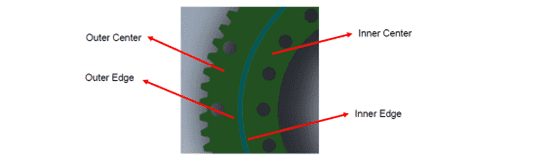

Picture 1 Slewing Bearing Surface Hardness Illustration

Table 5 Lily Bearing in Surface Flatness

| Inspected item from a failure Lily bearing | Results |

| Outer ring matching surface flatness | 0.030 mm |

| Inner ring matching surface flatness | 0.020 mm |

l Balls

Table 6 Balls Heat Treatment Comparison

|

Balls Heat Treatment Attribute/Brand |

KAYDON |

LILY |

|

Heat Treatment Specification |

"Through-hardening" process for Kaydon bearing's balls as per "SKF Slewing-bearing_tcm", pg57, but no specific hardness requirement provided. |

Ball hardness for Lily bearing is HRC 61-66, which matches with Kaydon's balls. |

|

Hardness Requirement |

HRC 64-65 |

HRC 61-66 |

|

Impact of Heat Treatment |

No specific impact of heat treatment on ball performance provided. |

No specific impact of heat treatment on ball performance provided, but the hardness values are comparable to Kaydon, indicating potentially similar performance. |

Grease Comparison

l Kaydon

Table 7 Appropriate Grease Lubricants for Kaydon Slewing Ring Bearings

|

Manufacturer |

Internal Bearing Grease |

|

BP |

Energrease LS-EP 1

|

|

Castrol |

HD Lithium 1 |

|

Chevron |

Dura-Lith Ep 1 |

|

ExxonMobil

|

Mobilux Ep 1 |

|

Klüber |

Klüberplex BEM 41-141 |

|

Lubricants USA (FINA) |

Marson EPL 1 |

|

Shell |

Alvania EP 1 |

|

Texaco |

Multifak EP 1 |

Table 8 Typical Characteristics of BP Energrease LS-EP 1 (Subject to usual manufacturing tolerances.)

|

Name |

Method |

Units |

LS-EP1 |

|

Appearance |

Visual |

|

Brown |

|

Texture |

|

|

Smooth |

|

NL GI Consistency |

|

|

1 |

|

Drop Point |

ASTM D2265 |

ºC |

185 |

|

Penetration@25 ºC |

ASTM D217 |

|

|

|

60 Strokes |

|

dmm |

325 |

|

100 000 Strokes |

|

dmm |

345 |

|

Water Content |

ASTM D128 |

% mass |

<0.1 |

|

EMCOR Rust Prevention |

IP 220

|

Rating |

0 |

|

Timken oK Load |

ASTM D2509 |

kg |

20 |

|

|

|

lb |

45 |

|

Oxidation stability(100 hrs) |

ASTM D942

|

bar |

0.30 |

|

Timken Corrosion |

IP112 |

Rating |

Pass |

|

(149 ºC,8hrs, Copper/Steel) |

|

|

|

|

Base Oil Viscosity @40 ºC |

|

|

155 |

l LILY

No. 2 lithium ester (Great Wall) is used as the grease lubricant of LILY bearing. LILY can customize grease as requested by the clients.

Table 9 Typical Characteristics No. 2 lithium ester (Great Wall)

|

Item |

No. 2 lithium ester (Great Wall) |

|

Appearance

|

light yellow to brown smooth ointment |

|

Application scope

|

Suitable for lubrication of rolling bearings, sliding bearings and other friction parts of general mechanical equipment |

|

Tech Spec |

GB7324 |

|

Working cone penetration 0.1mm |

280 |

|

Operating temperature

|

-20℃~120℃ |

|

Dropping point |

200°C |

|

Extended working cone penetration (100000 times 0.1mm) |

289 |

|

Water leaching loss (38℃, 1h) % |

1.60% |

|

Corrosion resistance (52℃, 48h) |

level 1 |

Visual Inspection

l Heat Treatment Marks

Picture 2 LILY VS Kaydon in Heat Treatment Marks

The difference lies in the result of different machining processes for raceway:

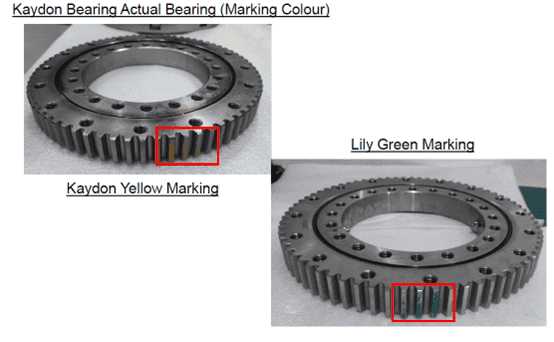

Picture 3 Actual Marking Color of LILY's and Kaydon's Real Bearings

1. The marks on teeth are indicated for teeth with minimum gear backlash. The color is defined by bearing supplier.

2. This is special for gear assembly.

l Position of Filler Plug and Grease Fitting

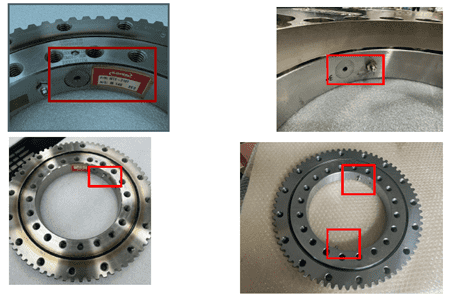

Kaydon LILY

Picture 4 Position of Filler Plug and Grease Fitting of LILY's and Kaydon's Real Bearings

1. Filler is used for balls installation and plugged in after that.

2. The position between filler and grease fitting is depend on bearing supplier and there is no relation to each other and not affect for utilization.

l Gear

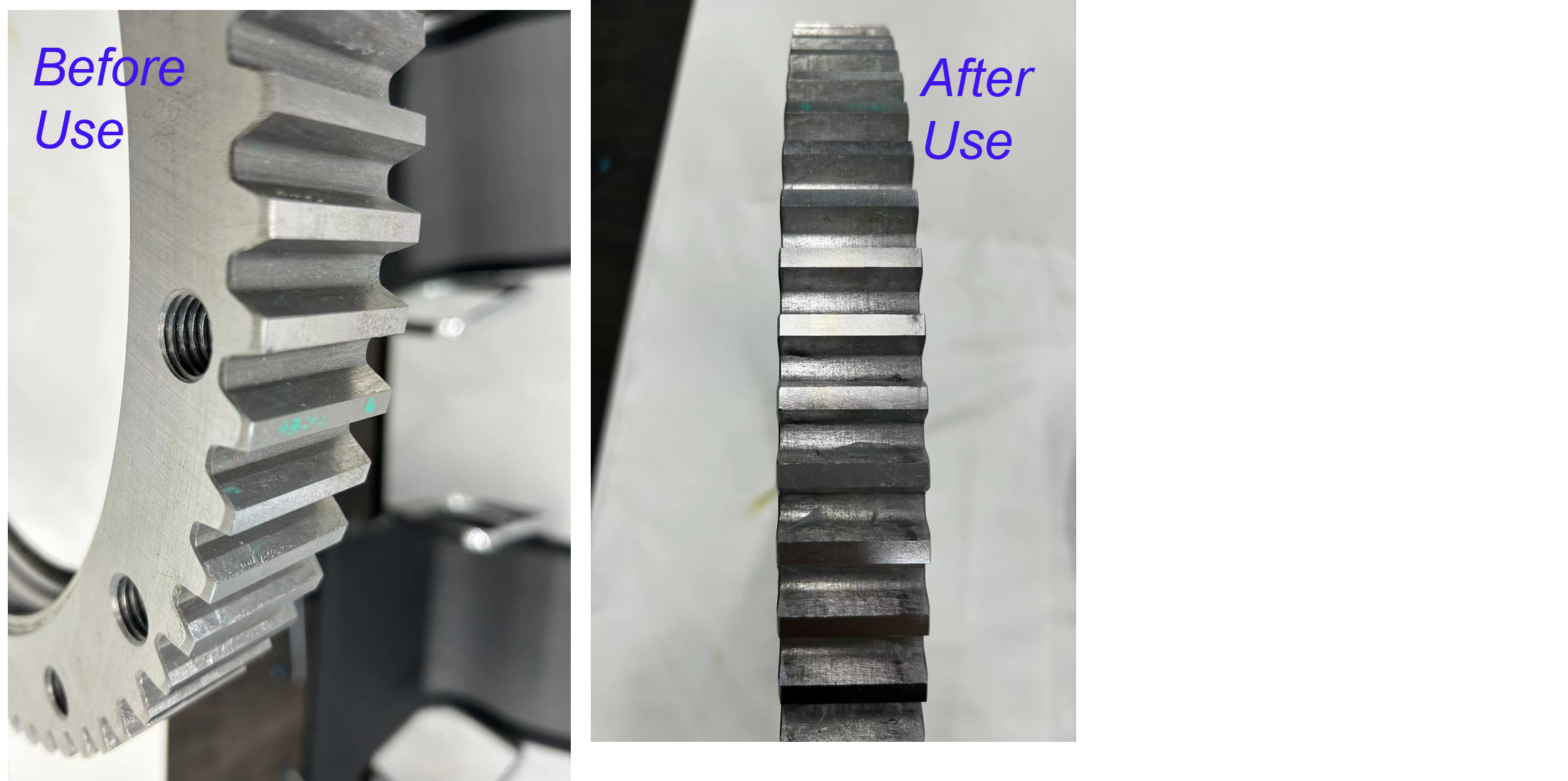

Picture 5 Before and After Use of LILY's Bearing

l Raceway of Inner Ring

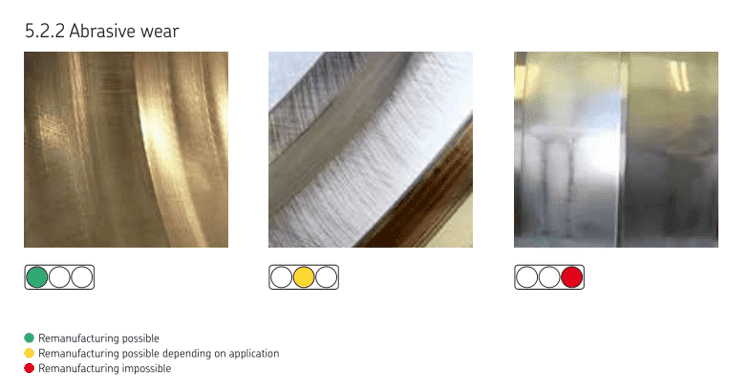

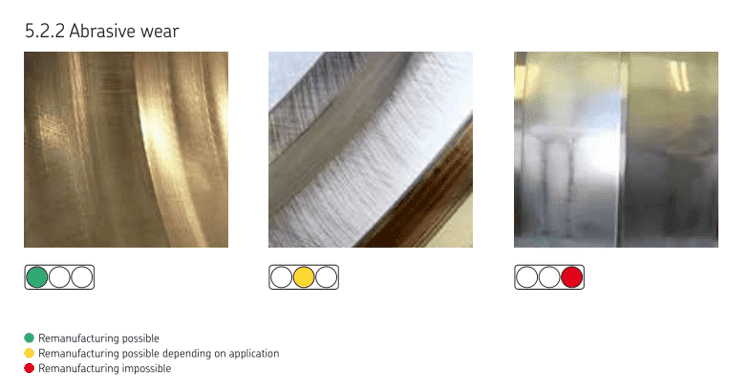

Picture 6 Various Raceway Failure Mode of Kaydon (Source: SKF Bearing damage evaluation guide.pdf)

No wear is observed inside the inner ring raceway of a failure Lily bearing.

Picture 7 Inner Ring Raceway of a Failure Lily Bearing

l Raceway of Inner Ring

Picture 6 Various Raceway Failure Mode of Kaydon (Source: SKF Bearing damage evaluation guide.pdf)

No wear is observed inside the outer ring raceway of a failure Lily bearing.

Picture 8 Outer Ring Raceway of a Failure Lily Bearing

l Balls

No wear, corrosion, cracks, etc. were found on the steel balls of a failure Lily bearing.

Picture 9 Balls of a failure Lily bearing

Size

Both Kaydon and LILY manufacture slewing ring bearings ranging for outside diameters of just 4 inches up to 282 inches (10 cm to 7.2 m). See Testing Report of PN MTE-210T.

Table 10 Testing Report of PN MTE-210T

|

Item |

Drawing |

Results (mm) |

|

|

LILY |

KAYDON |

||

|

Outer Diameter |

Φ373.02(0~-0.3)(14.686’’-0.015) |

-0.2 |

-0.25 |

|

Inside Diameter for the outer ring |

Φ293.19(0-0.12)(11.543’’-0.005~0) |

+0.02 |

+0.01 |

|

Inner Diameter |

Φ210(0~-0.3)(8.268’’-0.012) |

-0.25 |

-0.2 |

|

Outside Diameter for the inner ring |

Φ283.29(-0.12~0)(11.153’’-0.005~0) |

-0.08 |

-0.07 |

|

Height of outer ring |

38±0.3(1.496’’±0.012) |

0 |

+0.1 |

|

Height of inner ring |

38±0.3(1.496’’±0.012) |

-0.055 |

-0.1 |

|

Assemble height |

40±0.7(1.575’’±0.030) |

-0.04 |

-0.1 |

|

Jump of outside |

0.1 |

0.01 |

0.1 |

|

Jump of inside |

0.1 |

0.01 |

0.1 |

|

Axial clearance |

0~0.017 |

0 |

0 |

|

Mounting hole quantity of outer ring |

16 |

16 |

16 |

|

Mounting hole data of outer ring |

5/8-11UNC 2B |

5/8-11UNC 2B |

5/8-11UNC 2B |

|

Outer ring mounting hole centre diameter |

Φ335±0.25(13.19’’-0.015) |

±0.1 |

±0.1 |

|

Mounting hole quantity of inner ring |

20 |

20 |

20 |

|

Mounting hole data of inner ring |

5/8-11UNC 2B |

5/8-11UNC 2B |

5/8-11UNC 2B |

|

Inner ring mounting hole centre diameter |

Φ240±0.25(9.449’’-0.015) |

+0.1 |

+0.1 |

|

Inner ring oil hole |

2-1/8-27NPT |

2-1/8-27NPT |

2-1/8-27NPT |

|

Tooth quantity |

72 |

72 |

72 |

|

Inner ring hole spacing |

65.3±0.3 |

-0.04 |

-0.1 |

|

Outer ring hole spacing |

37.5±0.3 |

-0.06 |

-0.1 |

|

Round beat |

0.15 |

0.04 |

0.05 |

|

Common normal length (Number of teeth across: 9) |

132.596(-0.07~-0.14) |

-0.08 |

-0.1 |

|

Tooth Form |

Fellows stub pressure |

√ |

|

|

Angle |

20° |

√ |

|

|

Pitch Diameter |

365.75(14.4’’) |

√ |

|

|

Diameter Pitch |

5/7 |

√ |

|

|

Addendum |

3.05(0.1429’’) |

√ |

|

|

Whole Depth |

8.17(0.3215’’) |

√ |

|

|

Tooth thickness on pitch circle diameter |

-0.3142/0.3067 |

√ |

|

|

Allowance for backlash |

-0-0.0075 |

√ |

|

Rotation Accuracy

l Axial Clearance

Table 11 Test Result of Axial Clearance

|

No. |

Sample Brand |

Test duration

|

Test item |

Test result |

|

|

Standards (μm) |

Test data (μm) |

||||

|

1

|

Kaydon

|

Before axial static load test |

Axial internal clearance |

0~18

|

15

|

|

After axial static load test |

Axial internal clearance |

/ |

18 |

||

|

2

|

LILY

|

Before axial static load test |

Axial internal clearance |

0~18

|

4 |

|

After axial static load test |

Axial internal clearance |

/ |

6 |

||

l Test Results of Rotation Accuracy (Axial Run-out)

Table 12 Test Result of Rotation Accuracy

|

No. |

Sample Brand |

Test duration

|

Test item |

Test result |

|

|

Standards (μm) |

Test data (μm) |

||||

|

1 |

Kaydon |

Before axial static load test |

Kia |

150 |

26 |

|

Sia |

100 |

30 |

|||

|

Sea |

100 |

17 |

|||

|

After axial static load test |

Kia |

/ |

40 |

||

|

Sia |

/ |

45 |

|||

|

Sea |

/ |

30 |

|||

|

2 |

LILY |

Before axial static load test |

Kia |

150 |

25 |

|

Sia |

100 |

19 |

|||

|

Sea |

100 |

20 |

|||

|

After axial static load test |

Kia |

/ |

20 |

||

|

Sia |

/ |

20 |

|||

|

Sia |

/ |

12 |

|||

Field Testing of Axial Static Load Capacities

1. Static axial load test of LILY’s MTE-210T Slewing bearing was performed on May 10 in Shanghai Bearing Technology Research Institute (a leading 3rd party institute of bearing industry in China);

2. An axial loading of 3 Ton was applied on both sample of LILY's and Kaydon's bearings.

Test Methods

1. Initial Inspection: Conduct an initial inspection of the sample for the following items: internal diameter size, rotational accuracy (end runout of inner ring, diameter runout of inner ring, end runout of outer ring), and axial play.

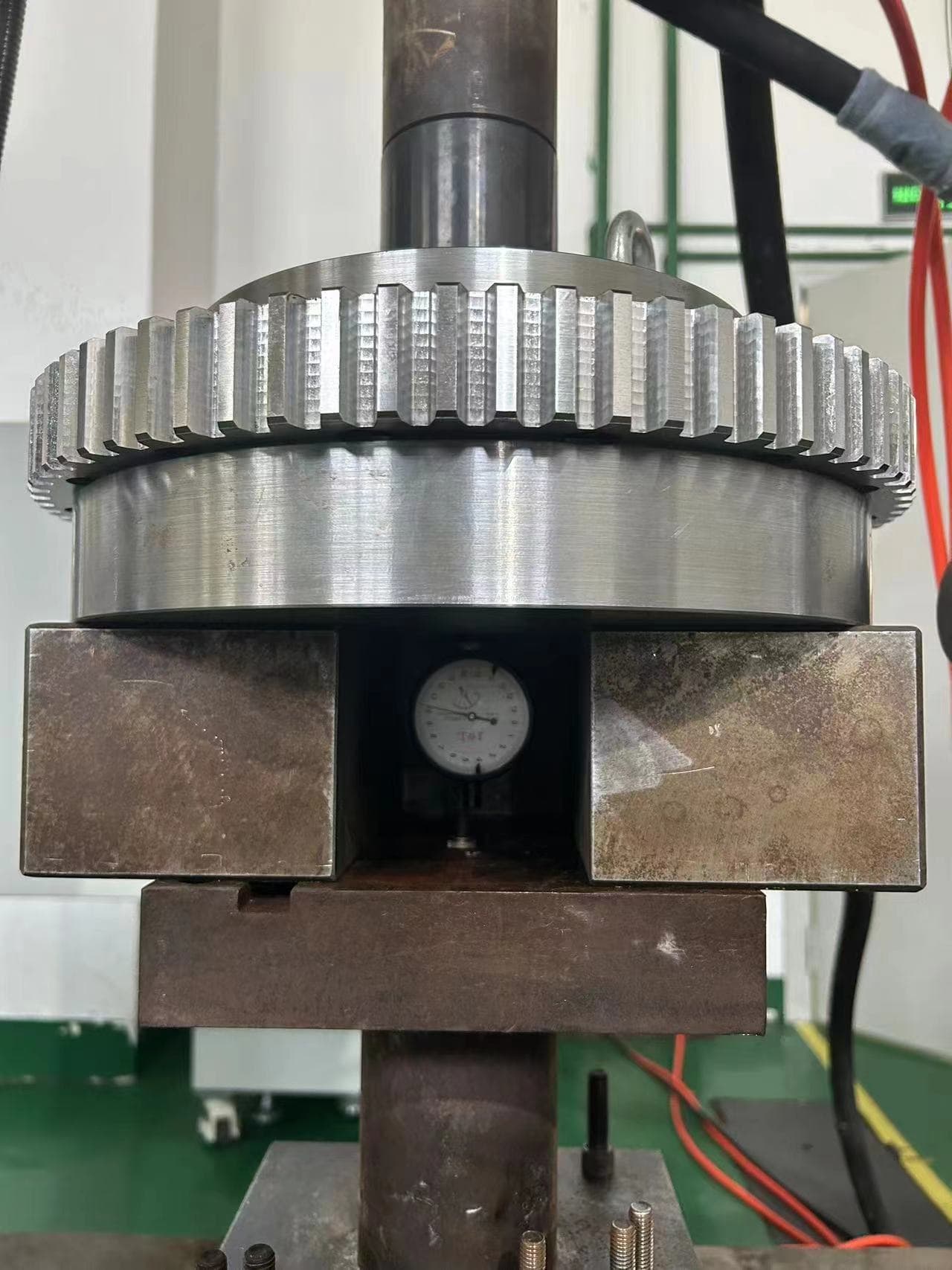

Picture 10 Initial Inspection

2. Axial Static Load Test:

Picture 11 Performing static load test

Attach the sample to the test rig, initially load with 1kN for 3 minutes, zero the indicator, then increase to 20kN at 0.2kN/second, hold for 3 minutes, note total deformation, and finally, decrease at the same rate to 1kN to measure permanent deformation.

Picture 12 Recording the value of the numerical rebound

3. Re-inspection of Sample: After the axial static load test is completed, re-inspect the sample for internal diameter size, rotational accuracy (end runout of inner ring, diameter runout of inner ring, end runout of outer ring), and axial play.

Picture 13 Re-inspecting the ample

4. Axial Static Load Test Result Comparison

Table 13 Axial Static Load Test Result

|

Sample Brand |

Pre-load(kN) |

Rating load (kN)

|

Total deformation (mm) |

Permanent deformation (mm)

|

|

Kaydon |

1.5 |

30 |

0.103 |

0.008 |

|

LILY |

1.5 |

30 |

0.076 |

0.006 |

5. Disassembled Checking

(1) Kaydon’s sample is not disassembled in accordance with the client requirement;

(2) LILY’s sample is disassembled, there are some curve tracks been found along circumferential direction on the groove in visual checking.

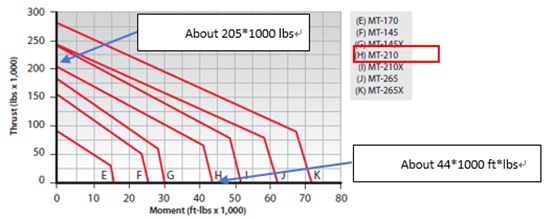

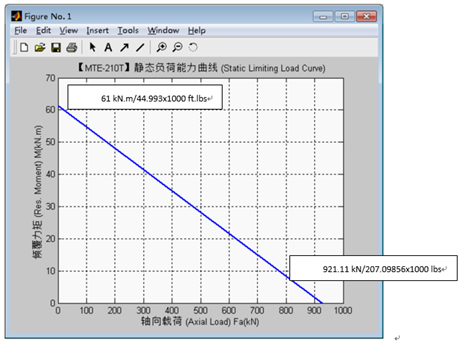

Thrust & moment curve comparison between Kaydon and LILY

The curves presented by both of LILY’s and Kaydon’s bearing almost matched ( invert coordinate system is needed for LILY).

Fig 1 Kaydon's Thrust & Moment Curve

Fig 2 LILY's Thrust & Moment Curve

Remarks: 1. The curve for LILY bearing was established from software called “SlewBrg V3.0”;

2. The curve for Kaydon bearing can be found from Kaydon catalogue of pg.70 “Kaydon _Catlog_390.pdf”;

3. More information about how LILY buildup the thrust & moment curve can be found from “Establishment of MTE-210T LILY slew bearing loading curve.pdf”.

Conclusion

The comparative analysis between LILY and Kaydon slewing rings focuses on several key aspects, including raw material, heat treatment, mechanical properties, and performance under load.

LILY's material has a higher carbon content, which generally leads to better hardness and wear resistance, contributing to better load-bearing capacity. LILY’s grease use can be tailored to customers’ requirement. Both Kaydon and LILY slewing ring bearings have shown similar performance under load.

The choice between them should be based on the specific requirements of the application, including the need for strength, wear resistance, and temperature tolerance. Regular maintenance and adherence to best practices will help ensure the longevity and reliability of the bearings.

Keep Learning