What are Cam Follower Bearings?

A cam follower, also called a cam and followers, is a specialized type of roller bearing or needle roller bearing designed to follow cam lobe profiles. As they can handle heavy loads and ensure precise movement,

Cam followers play a crucial role in various industries, such as automation and robotics, industrial machinery, automotive industry, food processing, and so on.

In this blog post, we delve into the world of cam and cam followers, exploring their types, working principles, key features, applications, maintenance and the tips on choosing the right ones for different applications.

Types of Cam Follower Bearings

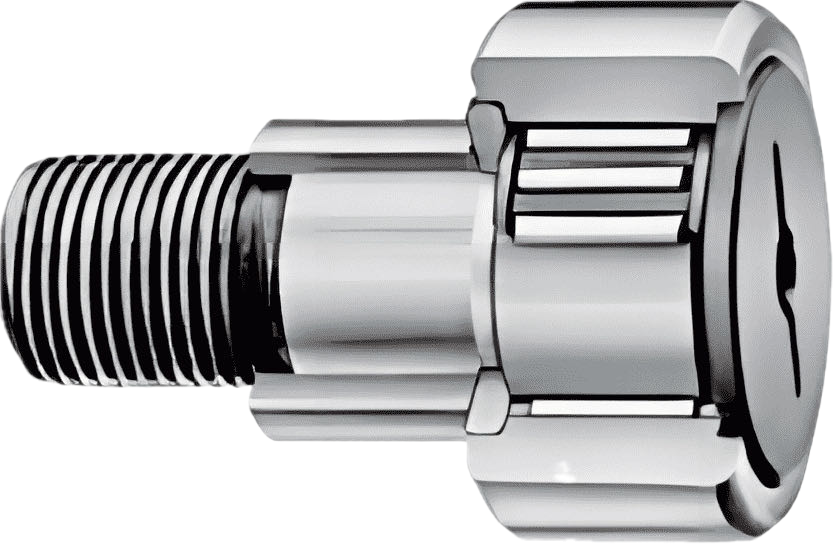

Stud Type Cam Followers

We categorize cam follower bearings into stud type cam followers and yoke type cam followers. Stud type cam followers feature a stud that serves as a mounting shaft, making them easy to install in various systems. These bearings are commonly used in applications where space is limited and a compact design is essential. The advantages of stud type cam followers include their straightforward installation and robust performance in high-speed production environments.

Yoke Type Cam Followers

Yoke type cam followers, on the other hand, have a yoke that allows them to be mounted on a shaft or bolt. This design provides greater load capacity and stability, making them ideal for heavy duty applications and applications that require complex vibrations. Yoke cam followers are often used in industrial machinery and automation systems where durability and precision are paramount.

How Do Cam Follower Bearings Work?

Cam with followers work by following the contours of a cam or track, with the cam acting as the driving force and the follower bearing responding to its motion in the bearing system.

This interaction allows cam follower bearings to convert rotary motion into linear motion efficiently. They are designed to handle static and dynamic imbalances, ensuring smooth and stable operation even under varying loads.

Key Features and Benefits

Cam followers are essential due to their many features. They offer high load capacity, precise motion control, durability, versatility, easy installation and maintenance, wear resistance, compact design, and so on.

Durability and Longevity

Cam follower bearings are crafted with premium steel, known for its strength and longevity. This choice of robust material offers exceptional wear resistance, ensuring these bearings endure a longer service life and maintain dependable operation, even in the most challenging environments.

Load Capacity

Cam follower bearings offer versatility by managing different types of loads, such as radial, axial, combined, and impact loads. They are essential in industries like heavy machinery, construction, automotive, aerospace, and plastic molding, where they support significant weight and resist high pressures. These bearings are designed for resilience, ensuring consistent performance even in the toughest conditions. Their ability to handle various load combinations makes them a reliable choice for high-load applications.

Versatility

Cam follower bearings are highly adaptable to different environments, excelling in conditions such as high-temperature environment, corrosive conditions, dust and debris, high-speed operations, vibration and shock, low-friction applications, washdown areas and space-limited applications. Their versatility makes them an essential component in a wide range of industries.

Applications of Cam Follower Bearings

Now let’s delve into various industries and applications where cam follower bearings are used.

Automation and Robotics

Cam follower bearings are essential for the seamless operation of automated systems and robotics. They offer robust support for applications that demand both high precision and the ability to handle substantial loads. These bearings contribute to the overall efficiency and durability of the machinery, ensuring a long-lasting and reliable performance.

Industrial Machinery

Cam follower bearings are key in many industries, offering both precision and strength. They handle hefty loads in metal and plastic processing, keep conveyors running smoothly, and ensure accuracy in textiles and printing. These versatile components are also ideal for fast-paced automation, tough agricultural work, and even delicate medical devices. They help keep everything running efficiently, whether in car factories, on farms, or in food and paper production.

Automotive Industry

Cam follower bearings are crucial in automotive applications, especially in engine valve trains, where they guarantee precise and timely valve operation. They also play a significant role in the smooth operation of suspension, transmission, and power steering systems. These components provide several advantages, such as accuracy, sturdiness, less friction, and increased reliability. Their low-maintenance design, along with their protective sealing, makes them perfect for the tough conditions of automotive engines. This, in turn, enhances vehicle performance and extends the service life.

Medical Equipment

Cam follower bearings play a crucial role in medical devices, providing the exact movements needed for surgical robots and diagnostic tools. They're dependable, ensuring steady performance that's vital for patient care. With low friction, these bearings help medical equipment run smoothly and last longer, which is great for both patients and healthcare providers. Their flexibility means they can be used in all sorts of medical gadgets, making healthcare technology better and more efficient.

Maintenance and Care

Maintaining cam follower bearings is essential for ensuring their longevity and optimal performance. Here are some tips and best practices for their maintenance:

l Regular Inspection: Periodically check the bearings for any signs of wear, damage, or contamination. Early detection can prevent more serious issues.

l Cleanliness: Keep the bearings and their surrounding area clean to prevent the ingress of dirt and debris, which can cause premature wear.

l Lubrication: Apply the correct type and amount of lubricant as specified by the manufacturer. Proper lubrication reduces friction and heat, prolonging the life of the bearings.

l Proper Installation: Ensure that the bearings are installed correctly, aligned, and tightened to the recommended torque. Misalignment can lead to uneven load distribution and accelerated wear.

l Avoid Overloading: Do not exceed the rated load capacity of the bearings. Overloading can cause excessive stress and damage.

l Seal Maintenance: Check the condition of the seals regularly. Damaged seals can allow contaminants to enter the bearing, leading to accelerated wear.

l Temperature Monitoring: Monitor the operating temperature of the bearings. Unusually high temperatures can indicate a problem such as insufficient lubrication or an alignment issue.

l Storage: Store bearings in a clean, dry environment to prevent rust or contamination before installation.

l Replacement: Replace bearings when they show signs of significant wear or when they fail. Continuing to use worn-out bearings can lead to system failure.

Common issues and solutions for troubleshooting cam follower bearings include:

l Noise: Excessive noise can indicate misalignment, insufficient lubrication, or a damaged bearing. Check alignment, lubrication, and inspect the bearing for damage.

l Overheating: High temperatures may be caused by inadequate lubrication or a blocked lubrication path. Ensure proper lubrication and check for any blockages.

l Fatigue: Repeated stress can cause fatigue in the bearing material. Ensure the bearing is not subjected to loads beyond its capacity and consider using bearings with higher load ratings if necessary.

l Corrosion: Corrosion can occur due to exposure to moisture or chemicals. Use corrosion-resistant materials or protective coatings, and ensure proper sealing.

l Seizure: Seizure of the bearing can be caused by insufficient lubrication or extreme temperatures. Regularly check and maintain lubrication and monitor temperatures.

l Wear: Excessive wear can be a result of misalignment, overloading, or abrasive contaminants. Correct any alignment issues, ensure proper load distribution, and keep the environment clean.

Choosing the Right Cam Follower Bearing

There are various cam follower brands to choose from, including Mcgill cam followers, LILY, SKF and so on. Choosing the right cam follower bearing is crucial for your application’s optimal functionality and longevity. Here’s a simple guide to help you make the best selection:

l Understand the Loads: Decide what types and sizes of loads the bearing will be supporting, including radial loads, axial loads, or a mix of both.

l Assess Operating Speed: Take into account the machinery’s speed. For high-speed operations, specific bearings that manage heat and friction well are needed.

l Evaluate the Environment: Consider the conditions where the machine will be running, including temperature, humidity, and potential contamination or corrosive elements.

l Consider Space Limitations: Make sure the bearing size fits within the available space in your design.

l Installation Factors: Think about how easy it is to mount and install the bearing, including the type of housing or bracket needed.

l Expected Life Span: Choose a bearing that matches your machinery’s maintenance schedule and lifecycle expectations.

l Material Compatibility: Ensure the bearing materials are suitable with the shaft materials to avoid galvanic corrosion.

l Sealing against Contamination: For dirty or wet environments, select bearings with effective seals to prevent contamination.

l Budget Considerations: While cost is important, it should be balanced with performance, reliability, and overall ownership costs.

l Manufacturer’s Guidance: Follow the manufacturer’s recommendations for bearings suitable for your application.

Application-Specific Guidance:

- High-Load Applications: Go for bearings with higher load capacity, like those with larger diameters or reinforced structures.

- High-Speed Applications: Choose bearings that reduce friction and heat, perhaps with ceramic materials or special designs.

- Corrosive Environments: Use bearings made with corrosion-resistant materials or coated for protection against chemicals.

- Limited Space: Opt for compact or miniature bearings that fit within your restricted space without reducing performance.

- Precision Applications: For robotics or medical devices, select precision bearings to ensure high accuracy.

- Maintenance-Intensive Environments: Consider bearings with a longer life or self-lubricating features if regular maintenance is challenging.

- Cost-Sensitive Applications: Strive for a balance between cost-effectiveness and the bearing’s performance to avoid early failures and increased long-term expenses.

By carefully reviewing these points and selecting a bearing that aligns with your application’s specific needs, you can ensure the bearing will deliver the necessary performance, dependability, and durability.

Conclusion

Cam follower bearings are vital for precision and load support in industries like automation and healthcare. They're available in stud and yoke types, adaptable for different spaces and loads. Regular maintenance and the right selection based on load, speed, conditions, and fit ensures efficient, reliable, and durable machinery operation.

Keep Learning