What Are Full Ceramic Bearings?

Introduction

Full ceramic bearings play a key role in industries that need high-performance components, such as aerospace, medical devices, and semiconductor manufacturing. Their features make them perfect for extreme environments where traditional bearings may fail.

In this blog, we will explore the key features, material composition, types, and applications of full ceramic bearings and more.

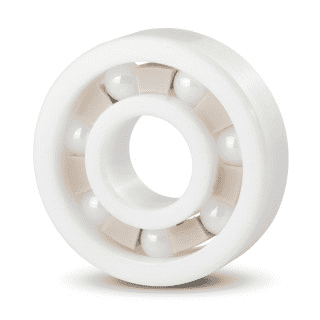

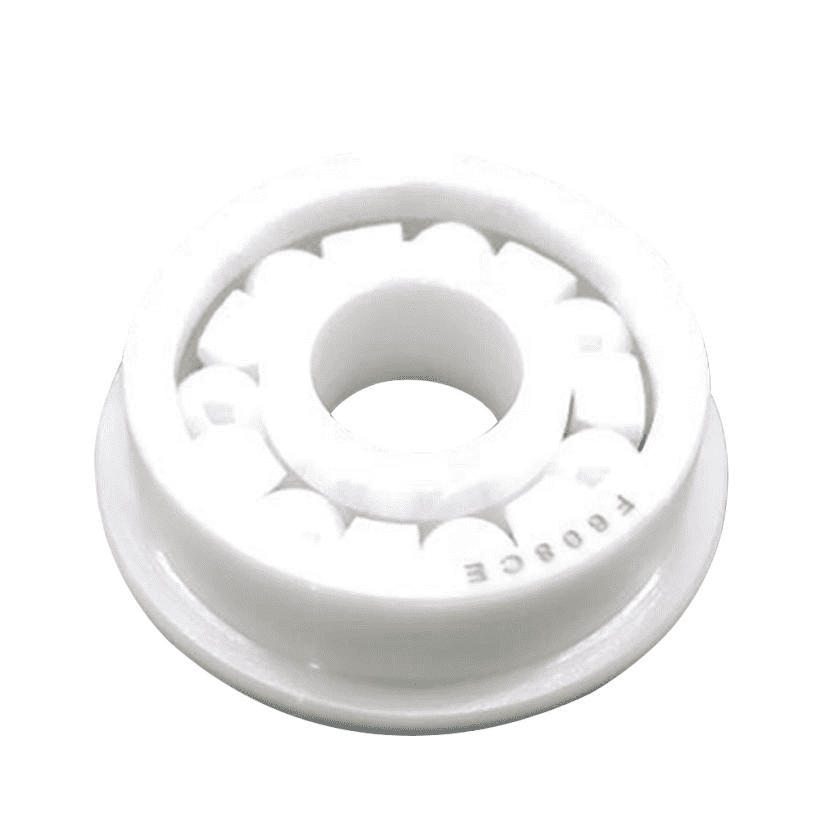

What Are Full Ceramic Bearings?

Full ceramic bearings are made entirely from ceramic materials for the inner and outer races and the rolling elements.

Construction and Material Composition

Here’s a brief introduction to each common ceramic material used for making full ceramic bearings:

- Silicon Nitride (Si₃N₄) : This material is very strong, resistant to fractures, wear, and corrosion.

- Zirconia (ZrO₂): This material is tough and resistant to wear and high temperatures.

- Alumina (Al₂O₃): This material is highly stable in thermal and chemical environments, offering great strength and hardness.

- Silicon Carbide (SiC): This material is highly resistant to wear, thermal shock, and corrosion.

Key Properties of Full Ceramic Bearings

Here are the key properties of full ceramic bearings that we’d like to highlight for you.

Corrosion Resistance

Full ceramic bearings are resistant to corrosion from water, chemicals, and salt. This makes them well-suited for harsh environments such as marine and chemical settings. They provide reliable performance in tough conditions.

High-Temperature Performance

Full ceramic bearings perform superbly well in extreme temperatures, ranging from -85°C to 800°C. This makes them ideal for industries such as medical devices, aerospace industry.

Lightweight and Low Friction

Full ceramic bearings are about two-thirds lighter than steel bearings, reducing inertia in high-speed applications. This weight reduction boosts efficiency where speed is crucial. Their low friction also minimizes wear and energy consumption, making them ideal for high-speed machinery and vacuum environments.

Electrical Insulation and Non-Magnetic Properties

Ceramic materials are non-conductive and can be used in medical devices and MRI machines. Full ceramic bearings do not interfere with magnetic fields. This makes them suitable for sensitive equipment.

Low Coefficient of Friction

Full ceramic bearings have an extremely low coefficient of friction. This feature enhances the efficiency of the machinery and prolongs the lifespan of the bearings.

Types of Full Ceramic Bearings

Full ceramic bearings come in various types, each designed for specific applications.

Deep Groove Ball Bearings

Ceramic deep groove ball bearings are ideal for high-speed applications needing precision and low friction. This makes them perfect for electric motors, robotics, and other high-speed machinery.

Angular Contact Ball Bearings

Angular contact ball bearings are perfect for high-precision tools and machine spindles. They support both axial and radial loads while handling high-speed rotations with minimal vibration.

Thrust Ball Bearings

Thrust ball bearings are ideal for applications where axial loads are primary. They are commonly used in centrifuges, turbomachinery, and pumps. These bearings handle thrust loads efficiently, ensuring reliable performance in high-stress environments.

Self-Aligning Ball Bearings

Self-aligning ball bearings compensate for misalignment between the shaft and housing. They are ideal for rotary equipment and machinery with shaft deflection.

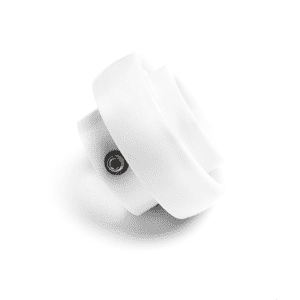

Insert Bearings

Insert bearings are easy to mount and provide excellent resistance to chemicals and moisture. This makes them ideal for environments with corrosive elements.

Tapered Roller Bearings

Tapered roller bearings are designed to handle large radial and axial loads. They are ideal for heavy-duty applications like automotive wheel hubs, mining equipment, and conveyor systems.

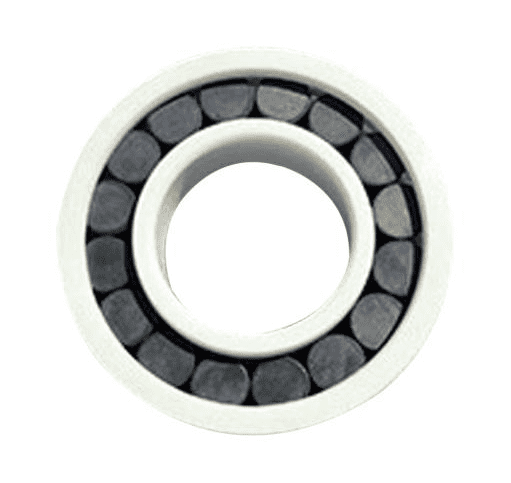

Cylindrical Roller Bearings

Cylindrical roller bearings are designed to handle high radial loads with minimal friction.

Flanged Ball Bearings

Flanged ball bearings simplify mounting in tight spaces and are ideal for compact designs.

Applications of Full Ceramic Bearings

Full ceramic bearings are used in various demanding applications, including:

Aerospace Industry

Ceramic bearings are widely used in the aerospace industry for jet engines, turbines, and high-performance systems. They withstand extreme heat and high-speed rotations.

Medical Equipment

In the medical field, ceramic bearings are essential for MRI machines, surgical tools, and diagnostic equipment.

Semiconductor Manufacturing

In semiconductor manufacturing, full ceramic bearings are used in vacuum chambers and high-precision instruments. Their low friction and non-magnetic properties help reduce impurities and ensure precision in cleanroom environments.

Marine and Offshore Applications

Ceramic bearings resist saltwater corrosion, making them ideal for marine engines, offshore oil platforms, and water-based applications. They offer long-term durability in harsh, corrosive environments. Their resistance to saltwater reduces maintenance needs.

Chemical Processing

In chemical processing, full ceramic bearings are used in pumps, valves, and other components exposed to aggressive chemicals.

Their exceptional chemical resistance ensures reliable performance in harsh environments. They help extend equipment lifespan and reduce maintenance.

High-Speed Machinery

Ceramic bearings excel in high-speed machinery such as dental drills, turbochargers, and centrifuges. They offer low friction and thermal stability, which are crucial for these applications.

Full Ceramic Bearings vs. Hybrid Bearings

Material Differences

Full ceramic bearings are made entirely of ceramic materials, including the inner and outer rings and balls. They provide excellent resistance to corrosion, high temperatures, and wear.

In contrast, hybrid ceramic bearings combine steel rings with ceramic balls. Ceramic balls in hybrid bearings reduce weight, friction, and increase speed, while steel rings provide strength and durability. Hybrid bearings are used when balancing performance and cost is important.

Performance Differences

Here’s a comparison between ceramic ball bearings and full ceramic bearings:

- Speed

Hybrid Bearings: These bearings support higher speeds than full steel bearings because ceramic materials are lighter and create less friction. This results in less heat and smoother operation.

Full ceramic bearings: These bearings can handle even higher speeds because of their lower mass and superior material properties. They often outperform hybrids in extreme speed applications.

- Flexibility

Hybrid bearings: These bearings use steel rings that offer flexibility and resilience. Steel's ductility helps absorb and distribute stresses better than some ceramics. This makes hybrid bearings suitable for applications with slight misalignments or shock loads.

Full Ceramic Bearings: Ceramic materials are generally more brittle than steel, which means full ceramic bearings are less flexible. They are less tolerant of misalignment or shock loads, which can make them more prone to damage under these conditions.

- Corrosion Resistance

Hybrid Bearings: Hybrid bearings use ceramic balls that resist corrosion but have steel rings that can rust. This limits the overall corrosion-resistant capability of the bearing.

Full ceramic bearings: These bearings offer excellent corrosion resistance. Both the balls and rings are made from ceramic materials. They are ideal for environments with high moisture or corrosive substances.

- Thermal Stability

Hybrid Bearings: Hybrid bearings can face thermal expansion issues between the steel rings and ceramic balls. Ceramic has high thermal stability and low expansion. Steel’s thermal properties can limit the bearing’s overall performance.

Full Ceramic Bearings: Full ceramic bearings excel in thermal stability. They can handle a wide range of operating temperatures without major changes in their properties.

- Load Capacity

Hybrid Bearings: Hybrid bearings generally have a higher load capacity compared to full ceramic bearings. This is because the steel rings, which are more robust and can handle higher radial and axial loads. The steel provides strength and toughness, making hybrid bearings suitable for applications where significant loads are expected.

Full ceramic bearings: These bearings generally have a lower load capacity than hybrid bearings. They excel in high-speed and high-temperature applications but are more brittle and less capable of handling heavy loads. The brittleness of ceramic materials limits their load capacity, making them more prone to cracking under high stress.

|

Feature |

Hybrid Bearings |

Full Ceramic Bearings |

| Speed |

Higher because of ceramic balls’ lower friction and density |

Higher because of ceramics’ superior properties |

| Flexibility |

Better with steel rings absorbing stress |

Less flexible as ceramics are more brittle |

| Corrosion Resistance |

Lower because steel rings can corrode |

Higher with both components made from corrosion-resistant ceramics |

|

Thermal Stability |

Lower because of steel rings affecting performance |

Higher as ceramics handle a wide temperature range well |

|

Load Capacity |

Higher because steel rings can handle significant loads |

Lower because of ceramics’ brittleness and limited load capacity |

Challenges and Limitations of Full Ceramic Bearings

Higher Cost

Full ceramic bearings are much more expensive than steel or hybrid bearings because of costly materials and complex manufacturing. The high price comes from the expensive ceramics and precise production needed, leading to a higher upfront cost.

Brittle Nature

Ceramic materials are more brittle than steel, offering excellent hardness but less toughness. This brittleness makes full ceramic bearings prone to cracking under heavy impacts or sudden shocks. Unlike steel bearings, which can absorb stress, ceramic bearings may fail if exposed to unexpected loads or impacts.

Lower Load Capacity

Full ceramic bearings have a lower load capacity than steel or hybrid bearings. Their brittleness limits their ability to handle high loads, making them less suitable for heavy-duty applications. They cannot withstand high stress without failure.

Specialized Applications

Full ceramic bearings are expensive and suited for specialized, high-tech industries like aerospace and high-speed machinery. Their high-speed capability and corrosion resistance are valuable in these fields. However, their cost and brittleness limit their use in standard applications. Compared to conventional bearings, they are less practical for everyday use.

Conclusion

Full ceramic bearings are excellent for high-speed, corrosion resistance, and thermal stability. However, their higher cost, brittleness, and lower load capacity limit their use. They are best for specialized, high-performance applications where these properties are essential.

If your industry could benefit from full ceramic bearings, Contact us today to learn more.

Keep Learning