Sign in

New customer? Start here

What are the Advantages of a One Way Bearing?

A one way bearing, also known as a "clutch bearing" or an " overrunning clutch". This one-way feature is important for the automotive industry that needs precise control of movement. This blog will explore the advantages of a one way bearing, including improved efficiency, high load capacity, and enhanced durability.

What Is a One Way Bearing

A one way bearing is a mechanical device designed to allow rotation in just one direction. What sets a one way bearing apart is its bevel or cam mechanism. This mechanism allows the bearing to rotate freely in one direction but stops reverse rotation. This design feature ensures that the bearing can only move in one direction.

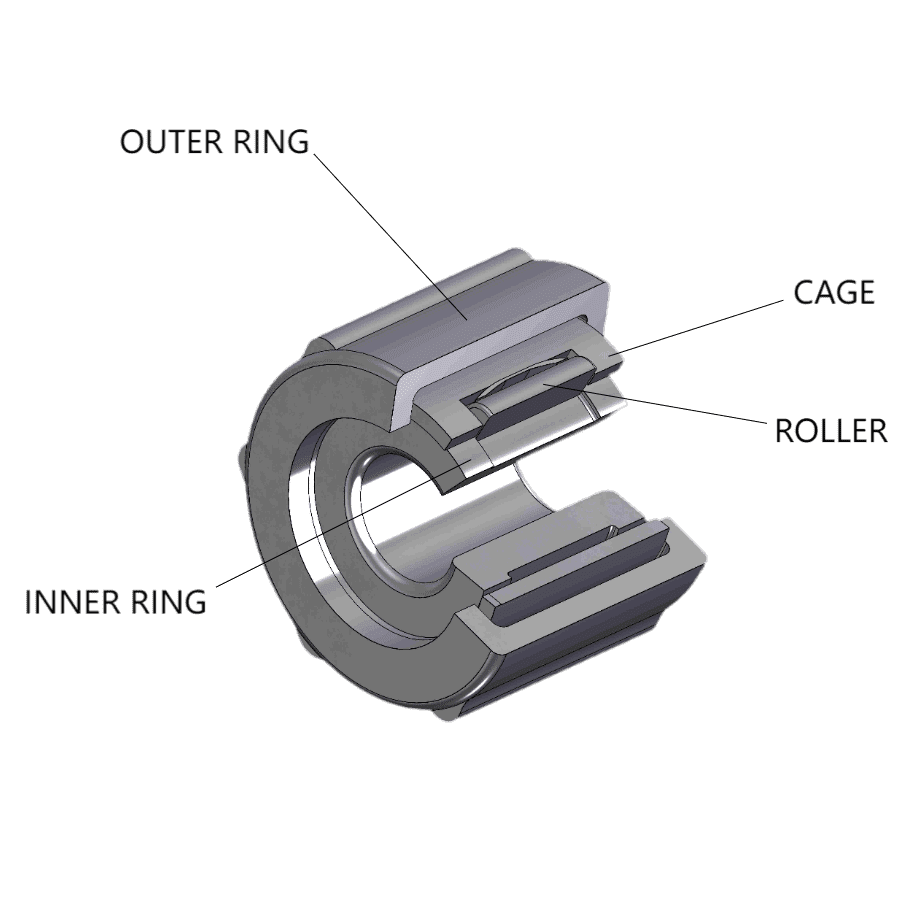

Key Design Elements of One Way Bearings

Needle Rollers

- Material: They are usually made from high-strength, heat-treated steel to withstand high loads and stresses.

- Dimensions: Needle roller clutches come in various sizes. They typically range from 2 mm to 30 mm in diameter and 5 mm to 100 mm in length. The exact sizes can change depending on the application and manufacturer.

- Arrangement: Needle rollers are usually placed parallel to each other in a bearing. They are evenly spaced and kept in position by a cage, which helps reduce friction and spread out the load during rotation.

Inner and Outer Races

- Material: They are usually made from hardened steel for strength and durability. This makes them able to handle high loads and resist wear.

- Surface Finish: The inner and outer races have a smooth, polished finish to reduce friction and help everything run smoothly.

- Design: These races are designed to fit together precisely. The inner race rotates inside the stationary outer ring.

Engagement Mechanism

- Sprags, Rollers, or Cams: These are mechanical components that engage with the races to lock the clutch in one direction. When turned in the opposite direction, the cam or ramp locks will prevent movement and ensure rotation only in the intended direction.

- These elements tilt, roll, or wedge into place to enable or disable motion based on the rotational direction. When turned the other way, the cam or ramp locks in place, preventing any movement. This makes sure the bearing only rotates in the intended direction.

Cage or Retainer

- Function: The bearing cage or retainer keeps the rollers evenly spaced and in position. This helps everything run smoothly and reduces friction.

- Material: They are usually made from materials like steel, brass, or plastic. These materials are chosen for their strength, durability, and low friction.

Mechanical Advantages of a One Way Bearing

These mechanical advantages make a one way bearing essential components in various applications, as follows:

Prevention of Backward Movement

- A one way bearing stops backward movement using a special locking mechanism. It allows rotation in one direction while locking to prevent movement when turned in the opposite direction. This keeps machines running safely and as intended.

- For example, in conveyor systems, a one way bearing stops the equipment from moving backward. This ensures it runs properly. Another example is in machines that need to rotate in only one direction, a one way bearing helps support and control the movement.

Increased Efficiency

- A one way bearing improves mechanical systems by stopping backward movement and reducing friction. It also enhances safety and requires less maintenance.

- A one way bearing helps machinery use less energy and last longer by reducing friction and stopping backward movement. This makes the machines run more efficiently and reduces the need for repairs.

Design and Performance Advantages

The streamlined design of the a one way bearing greatly improves manufacturing efficiency. With fewer components and less assembly time, it enhances performance, reduces costs, and boosts functional efficiency.

Simplified Design

A one way bearing contributes to simpler mechanical designs by:

- Reducing the Need for Complex Controls: It automatically allows rotation in one direction, so no extra parts are needed to control it.

- Simplifying Maintenance: With fewer moving parts and less wear and tear, it is easier to maintain and repair.

- Compact and Efficient: Its compact design fits into smaller spaces while still providing reliable performance.

Enhanced Durability

The strong construction of a one way bearing uses high-quality materials and precise engineering. It features advanced design and effective lubrication. This combination ensures a longer lifespan. This durability means reliable performance, less maintenance, and cost savings over time.

These examples highlight how various industries benefit from the durability of a one way bearing:

- Renewable Energy: Reliable operation, longer equipment life, and reduced maintenance.

- Agriculture Industry: The one way bearing has robust performance in harsh conditions and fewer breakdowns.

- Mining Industry: High durability in demanding environments and reduced downtime.

Versatility and Application Advantages

The one way needle roller bearing is a versatile component that can offer significant advantages across a wide range of applications.

Automotive Industry

- Vehicle Suspension Systems: A one way bearing helps manage force direction and reduces wear on suspension parts. It also improves ride comfort and handling stability.

- Transmissions: It ensures efficient power transfer and extends the lifespan of transmission parts by reducing friction and wear.

- Starter Motors: This prevents starter motor damage and ensures it disengages once the engine starts.

Industrial Machinery

- Conveyor Systems: A one way bearing prevents backsliding, ensuring smooth material flow.

- Indexing Mechanisms: The bearing allows precise, incremental movements for accurate positioning.

- Over-Running Clutches: It protects components by allowing freewheeling, preventing damage during overrun conditions.

Recreational Equipment

- Bicycles: The bearing provides smooth and efficient pedaling, improves rider control, and enhances overall cycling experience.

- Fitness Equipment: A one way bearing ensures smooth operation and reduces wear and tear. It also enhances the durability of fitness equipment.

- Scooters: The one way bearing is used in the drive systems of scooters. It allows for smooth acceleration and freewheeling when coasting.

Aerospace Industry

- Aircraft Landing Gear: A one way bearing ensures smooth operation of the landing gear. It securely locks in place when extended or retracted. This prevents unintended movements and enhances safety.

- Engine Systems: The bearing ensures the engine starts smoothly by engaging the starter motor. It then disengages once the engine is running, preventing starter damage.

Medical Equipment

- Surgical Instruments: The one way bearing ensures accurate and reliable performance during delicate procedures. It enhances surgical outcomes and patient safety.

- Imaging Equipment: The bearing ensures accurate positioning of imaging parts. It results in high-quality images and better diagnostics.

Maintenance and Care of One Way Bearings

Proper maintenance and care are essential to ensure the optimal performance and longevity of a one way bearing. Here are key guidelines to follow:

Regular Inspection

- Preventive Maintenance: Schedule regular check-ups and follow the manufacturer's maintenance instructions.

- Ensuring Reliability: Inspect for any signs of irregular motion or noise, which can indicate potential issues.

- Extending Lifespan: You should lubricate the bearing regularly and replace any worn-out parts immediately.

Proper Lubrication

- Regular Lubrication: Apply lubricant regularly based on usage and manufacturer's advice.

- Use the Right Lubricant: You must use the correct type and grade of lubricant specified for the bearing.

- Keep Lubricants Clean: Bearing lubricants must be free from dirt and debris to maintain optimal performance. This cleanliness is essential to extend the lifespan of the machinery.

- Check Lubrication Levels: Regularly check and maintain the proper lubrication levels.

Cleaning and Storage

- Remove the Bearing: Carefully remove the bearing from its housing to avoid any damage.

- Dry Completely: You should allow the bearing to air dry completely. And use compressed air to speed up the process. However, avoid spinning the bearing with compressed air to prevent any potential damage.

Expert Recommendations

We offer custom solutions to fit your specific needs. A one way bearing can be tailored to ensure optimal performance in your unique conditions.

Selection and Compatibility

- Choose the Right Size: Ensure the one way bearing fits the required dimensions for your application. Verify that it can handle the necessary load capacities.

- Material Suitability: You can select bearings made from materials compatible with your operating environment to avoid corrosion and premature wear.

Installation Best Practices:

- Proper Alignment: Ensure the one way bearing is correctly aligned during installation. Proper alignment prevents uneven wear and potential failure.

- Avoid Overloading: Do not exceed the bearing's specified load capacity to maintain performance and longevity.

Operating Conditions

- Monitor Operating Temperature: Keep the one way bearing within its recommended temperature range to prevent overheating and degradation.

- Check for Contaminants: Regularly inspect the bearing environment for contaminants that could lead to premature failure.

Case Studies and Real-World Examples

- The one way bearing in Toyota's automatic transmissions made gear shifts smoother, improved fuel efficiency, and reduced breakdowns. This extended the vehicle's life and made driving more enjoyable.

- Shimano, a top bicycle component maker, wanted to improve their freewheel mechanisms. They added one-way bearings to the freewheel assembly. This resulted in smoother pedaling and less resistance when coasting. Cyclists experienced better performance and increased product reliability.

- John Deere aimed to make their farm equipment more efficient and durable by adding a one way bearing to key parts like harvesters and tractors. This reduced downtime and repairs, while increasing productivity and lowering maintenance costs. These improvements helped John Deere maintain its reputation for reliability and efficiency.

Conclusion

This article provides a deeper understanding of the one way bearing, its advantages, and the reliability in transmitting high torque. A one way bearing offers many benefits that can greatly improve the performance and reliability of your systems. For further inquiries or purchases, contact LILY Bearing to get professional guidance on bearing selection.

Keep Learning