What Does the Cam Follower Do?

Cam followers, also known as cam and followers, are crucial parts in many mechanical systems. They convert rotational motion into linear motion, making them vital for the smooth operation of machinery. You can find them in everything from industrial equipment to precision instruments. Knowing how cam followers work helps you understand their importance in mechanical systems.

Understanding Cam Followers

What is a Cam Follower and its Basic Function

A cam follower, or a cam with follower is an engineering device that transforms rotational movement into linear movement. This device has two main parts: the cam, a rotating element with a special shape, and the follower, which moves by sliding or rolling.

As the cam rotates, it propels the follower, effectively transforming motion from rotational to linear. This type of mechanism is utilized in a range of applications such as automotive engines, pumps, and automated machinery.

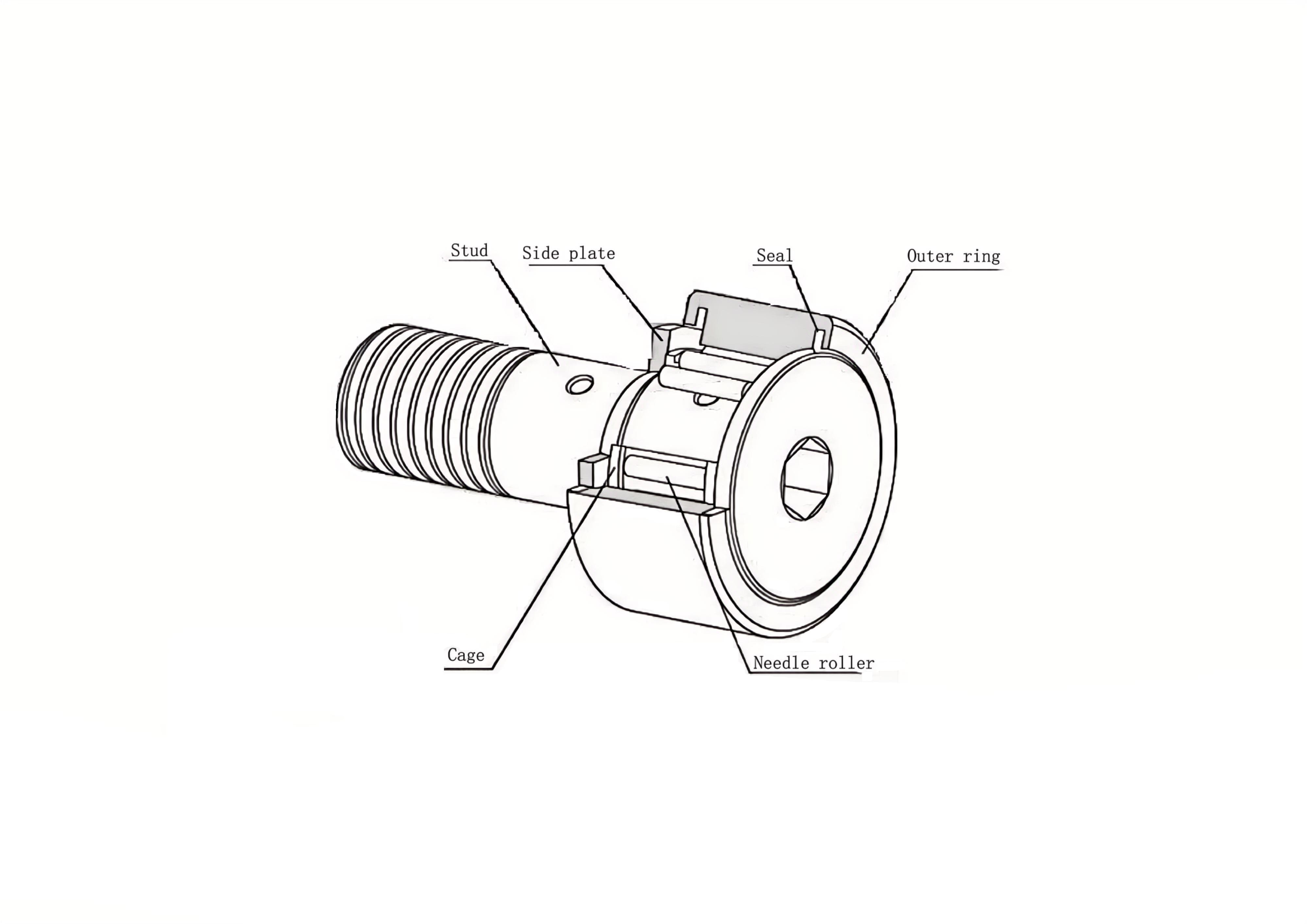

Components of a Cam Follower Bearing

Cam followers, or cam and cam followers, consist of several key components:

Outer Ring: The outer ring rolls along the cam profile, reducing friction.

Stud or Yoke: This is the mounting component that attaches the cam follower to the machinery.

Rolling Elements: These can be balls, rollers, or needle bearings that facilitate smooth rotation.

Seals: Seals prevent contaminants from entering the bearing and retain lubrication.

Side plate : End plates in cam followers secure the rolling elements in place and distribute loads evenly to prevent undue stress. The also ensure proper alignment for smooth operation. Additionally, end plates offer easy access for lubrication, helping to reduce friction and wear over time.

Stud: Stud on a cam follower provides mounting, supports load, and ensures precise alignment for reliable operation.

Cage: Cage in a cam follower guides rollers, reduces friction, and maintains even load distribution for stable performance.

Types of Cam Followers

There are two primary types of cam follower bearings: the stud type rollers and the yoke type rollers. Each of these features a stem or shaft that projects from the inner race.

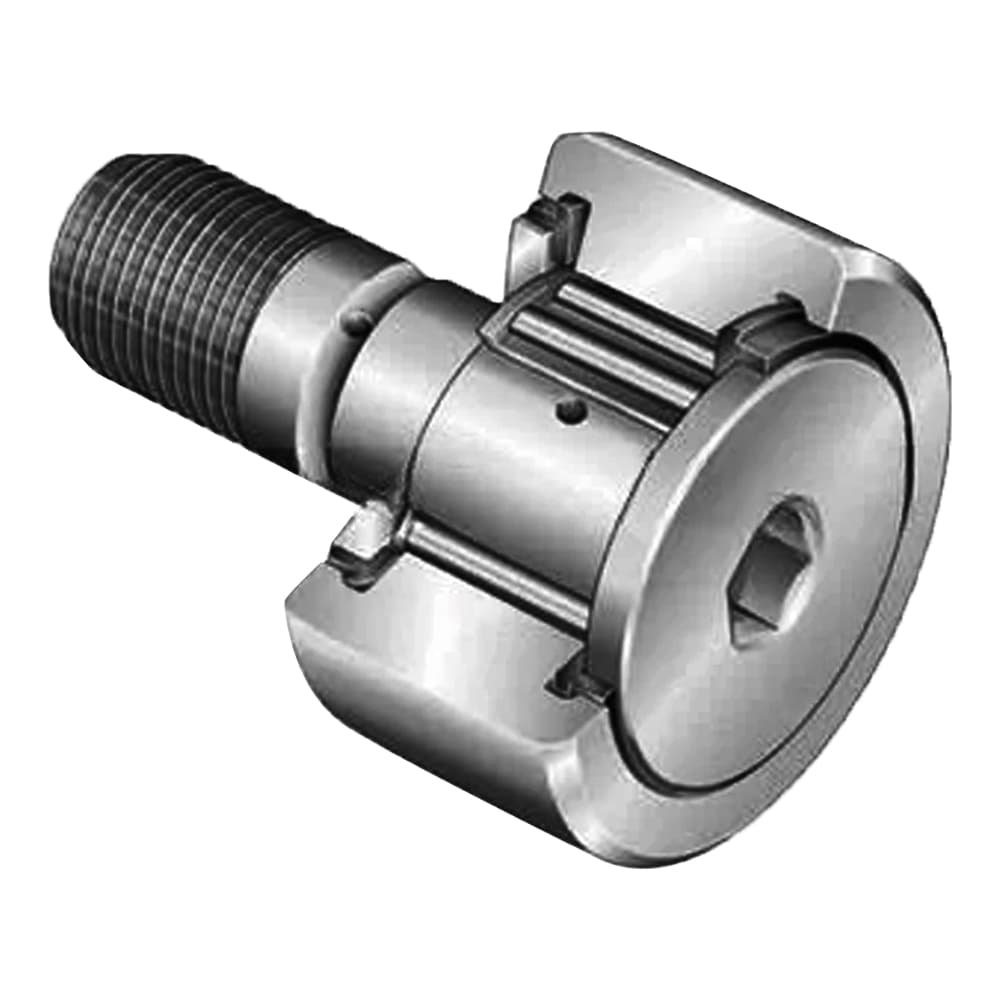

Stud Type Rollers

Stud type rollers have a threaded stud that allows them to be easily mounted onto machinery. They are equipped with a threaded stem that is specifically tailored for attachment into a corresponding threaded hole. This configuration is perfect for tasks that need a compact and robust assembly.

These items are usually offered in standard sizes. For those seeking enhanced durability, there are heavier-duty alternatives designed to handle higher levels of static loads. They are commonly used in applications where space is limited and a compact solution is needed.

Fig 2 Stud Type Roller

Yoke Type Rollers

For the yoke type, or yoke rollers, the stem is typically hollow and designed to fit over a stub shaft. This design allows for smooth linear motion and is ideal for applications requiring stabilization across a wide support area.

Yoke type cam followers are ideal for applications requiring higher load capacities and greater rigidity. They are engineered to handle heavy loads and provide smooth rotational movement in many industrial applications.

Fig 3 Yoke Type Roller

What Does a Cam Follower Do?

Rolling Motion

Cam followers incorporate rolling elements such as balls, rollers, or needle bearings between the inner and outer rings. These rolling elements significantly reduce friction through rolling motion rather than sliding. This rolling action reduces contact stress and surface wear, allowing for smoother movement and extended service life. The even distribution of load across multiple rollers also enhances bearing efficiency and performance.

Interaction with Cams

Cam followers interact with cams to precisely convert rotational motion into linear movement. As the cam rotates, its unique shape interacts with the follower, guiding it along a controlled path.

This connection is crucial for managing different mechanical tasks, such as running engine valves or powering machinery in automation. A well-designed cam is key to ensuring smooth functioning and long life of the system, highlighting the importance of how they work together.

Load Distribution

Cam followers are engineered to handle both radial and axial loads effectively. The rolling elements distribute these loads evenly within the bearing, ensuring stability and preventing premature wear. The ability to distribute weight makes cam followers ideal for heavy-duty tasks.

High-speed Operation

In high-speed applications, cam followers play a vital role in maintaining performance and reliability. Their design allows them to operate smoothly at high speeds, reducing the risk of overheating and ensuring consistent operation.

Applications of Cam Followers

Industrial Machinery

Cam followers play a key role in industrial machines like conveyor belts, automation systems, and heavy machinery. They turn spinning motion into straight-line movement. These components are crucial for things like operating valves in engines, keeping assembly lines moving smoothly, controlling packaging machines, and aiding in the precise movements of robots. This motion conversion is vital for coordinating mechanical actions, making sure everything runs efficiently, reliably, and smoothly in different industrial tasks.

Automotive Engines

Cam followers are key components in car engines, where they activate the valve train. They turn the camshaft's spin into the straight-line action necessary to open and shut the engine valves. This regulated action is essential for letting in air and fuel and managing exhaust, leading to effective combustion and engine power. The accuracy of cam followers directly affects engine efficiency, dependability, and the smooth operation of the vehicle.

Advantages of Using Cam Follower Bearings

Durability

Cam followers are remarkably durable, even under tough conditions. They shine in their ability to handle heavy loads and thrive in harsh environments, ensuring a long service life that stands the test of time and demanding operations.

Efficiency

Cam followers boost mechanical efficiency by minimizing friction and energy loss, leading to cost savings and better performance. Designed for low friction, they consume less power and ensure smooth operation with precision rolling elements.

Enhanced materials and specialized heat treatments allow for improved load handling, high efficiency, and reliable performance. These bearings are key in systems that need fast, precise movements with optimal energy efficiency.

Versatility

Cam followers are flexible parts found in many industries. They work in a variety of settings, from car engines and heavy industrial machines to precise instruments and automated systems.

They help with different motion control tasks, effectively changing spinning motion into straight motion. With a range of designs, like various roller types and setups, they fulfill the unique needs of different industries, making them essential in many mechanical systems.

Choosing the Right Cam Follower

Factors to Consider

There are various cam follower brands to choose from, including mcgill cam followers, LILY, SKF and so on. When choosing the right cam follower, take into account the specific requirements of your application:

- Load Capacity: Ensure the cam follower can handle the expected loads.

- Motion Precision: Select a cam follower that offers the necessary precision for your motion requirements.

- Speed: Ensure the cam follower is capable of performing dependably at your required operational speed.

- Environmental Conditions: Consider how well the cam follower will work in its environment. Take into account factors like temperature, mosture, and any contaminants.

Moreover, consider these factors:

Cam Profile Suitability: Ensure the cam follower matches the cam profile for smooth operation.

- Material Fit and Longevity: Pick materials that match your needs and last a long time.

- Design for Maintenance: Look for a cam follower design that allows for easy maintenance and lubrication.

- Space Constraints and Mounting Options: Ensure the cam follower fits within the available space and can be easily mounted.

- Choose Quality and Dependability: Select cam followers made by trusted brands to guarantee they are high-quality and reliable.

Ultimately, select a cam follower that meets your mechanical system's needs for optimal performance and long service life.

Material and Design

Selecting the right cam follower involves careful consideration of both material and design. Here are some key points to keep in mind:

- Material Selection: Choose robust materials such as stainless steel for corrosion resistance and high-carbon steel for strength.

- Design Features: Pay attention to the cam follower's design, including the type of roller, cage construction, and sealing options.

- Compatibility: Ensure the cam follower is compatible with the cam profile and meets lubrication requirements.

- Performance Factors: Consider thermal stability, wear resistance, and load-bearing capacity.

- Ease of Use: The design should allow for easy installation and maintenance. This ensures longevity and meets the specifc demands of the application.

Maintenance of Cam Followers

Regular Inspection

Regular inspection is essential for maintaining cam followers. Here are the key steps:

- Check for wear, damage, or dirt.

- Ensure proper alignment and lubrication.

- Monitor the condition of rollers and raceways.

- Confirm that the follower moves smoothly without binding.

- Inspect seals for integrity and replace them if necessary.

- Early detection of issues can prevent failures, extend service life, and maintain optimal performance. Scheduled maintenance reduces downtime and ensures reliability.

Lubrication

Lubrication is crucial for cam follower maintenance as it reduces friction and wear. Follow these guidelines:

- Use the correct type and amount of grease or oil for the operating conditions.

- Regularly check and replenish the lubricant to prevent dry operation.

- Ensure lubrication points are free from contamination.

- Proper lubrication extends bearing life, enhances efficiency, and reduces the risk of premature failure. Make bearing lubrication a part of your maintenance routine for reliable performance.

Conclusion

Cam followers are essential for machines, enabling smooth movement and managing heavy loads. They're durable, efficient, and fit for many uses, from big industry machines to detailed instruments. The right cam follower, well-maintained, keeps your equipment running at its best for longer. For top-notch cam followers that suit your needs, count on LILY Bearing for dependable and effective solutions.

Keep Learning