What is the Tilting Moment of a Slewing Bearing?

In the world of mechanical engineering, the tilting moment of slewing bearings are key to how machinery runs and how long it lasts. It happens when there are forces acting on the bearings in systems that turn. If we don't pay attention to these moments, it can lead to machines not working well, safety problems, and bearings wearing out faster. This article talks about why it's so important to figure out the tilting moments in slewing bearings of construction equipment, wind turbines, and robots.

Understanding Slewing Bearings

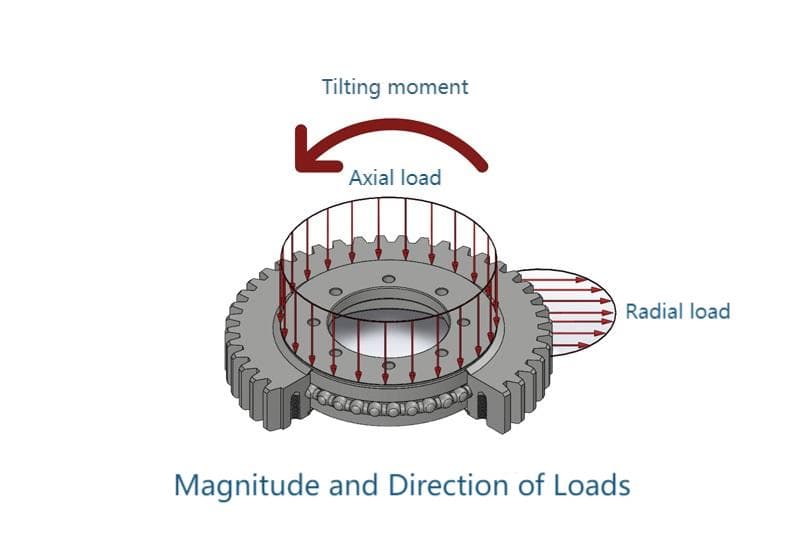

Slewing bearings, sometimes called turntable bearings or slewing ring turntable bearings, are made to deal with different kinds of forces: axial, radial, and moment loads. These bearings are what let machinery spin all the way around, such as in cranes, excavators, and wind turbines.

Key Parameters of Slewing Bearings

- Load Capacity: Slewing bearings are crafted to manage particular axial, radial, and moment loads. These load specifications are vital in deciding the appropriate size and setup for the bearings.

- Rotation Speed: The rotational speed of a bearing is a key factor in determining its choice and how well it performs. Generally, for applications requiring faster speeds we need more refined engineering techniques.

- Other Critical Factors: Proper sealing, effective lubrication, and consistent maintenance are crucial. These elements ensure the bearing runs smoothly and remains durable over time.

What is the Tilting Moment?

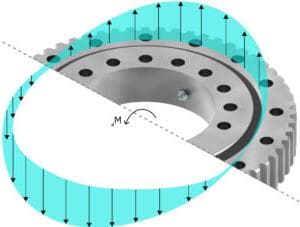

In slewing bearings, a tilting moment is the twist that happens when the load isn't exactly on top of the bearing's middle. This moment can cause the bearing to tilt, leading to uneven load distribution and potential damage.

Axial and radial moments are forces that either run along the bearing's axis or push against it straight on. On the other hand, a tilting moment is a force that comes in at a slant, kind of like a sideways push. If you don't handle this force just right, it can make the bearing go out of whack.

Factors Influencing Tilting Moment

- Load Distribution: When loads are not spread evenly, they create tilting moments. This happens because forces are hitting the slewing bearing in a way that's not straight down the middle. This creates a lever arm, inducing a rotational effect. Handling this effect well is super important. It keeps the bearing working just as it should and extend the life of both the bearing and the related machinery.

- Structural Rigidity: The rigidity of the slewing bearing and the parts around it plays a big role in how well they can handle tilting moments without bending or breaking. Designs like crossed roller bearings, have multiple contact points. This provide high rigidity to effectively counteract tilting moments.

- Bearing Design: Cross roller slewing bearings really shine in tough spots because they're super sturdy and can handle high load, so they do a great job of fighting against tilting moments. Four-point contact bearings, on the other hand, are good at keeping things steady by spreading out the load and making tiny adjustments if things aren't perfectly lined up.

Calculating the Tilting Moment

Theoretical Calculation

The tilting moment (Mt) can be calculated using the formula: Mt=F×d

where F is the force applied at a right angle to the axis of rotation, and d is the distance from the center of the bearing to the point of force application.

Practical Example

Let's walk through a real-world example of calculating the tilting moment for a slewing bearing in a crane. We'll also discuss potential challenges and considerations in the calculation process.

Example: Calculating Tilting Moment for a Crane's Slewing Bearing

Step 1: Identify the Parameters

- F (Force): Determine the weight of the load (W) being lifted by the crane.

- d (Distance): Measure the distance from the center of the slewing bearing to the point where the load is applied.

Step 2: Crane Movement and Load Variation

- Consider the dynamic nature of the crane operation. Loads can shift, and the crane's movement (hoisting, swinging) can alter the force's direction and magnitude.

- If the crane is mobile, additional forces due to its movement on uneven terrain or during wind gusts must be considered.

Step 3: Environmental Factors

- Wind Load: Calculate the additional force exerted by wind on the load and crane structure.

- Temperature: Changes in temperature can affect the material properties of the crane and the load.

Step 4: Calculate the Tilting Moment

- Use the formula for tilting moment, T=F×d, where τ is the tilting moment, F is the force (including weight and any additional forces like wind), and d is the perpendicular distance from the bearing's center to the force application point.

Step 5: Safety and Design Considerations

- Factor of Safety: Include a safety factor to account for uncertainties and potential overloads.

- Material Fatigue: Consider the material's fatigue life under repeated loading and unloading.

Calculating tilting moments for cranes faces challenges like:

- Handling loads that move when lifting or due to wind.

- Measuring force and distance very accurately.

- Considering how weather, especially wind and temperature, affects forces.

- Thinking about how the crane's structure might not be totally stiff.

- Planning for parts wearing out over time.

- Following safety rules, which can make things more complicated.

Impact of Tilting Moment on Bearing Performance

Effects on Bearing Life

If a slewing bearing has to deal with too many tilting moments, it can cause a lot of stress, wear out faster, and not last as long. To avoid this, pick the right bearing, make sure the structure is well-designed, and do regular maintenance. By spreading the load out evenly and keeping tilting moments to a minimum, you can make the machinery more dependable and efficient.

Effects on Operational Efficiency

Tilting moments reduce machine efficiency by increasing energy use due to the extra force needed to counteract them. They also cause vibrations that decrease accuracy and speed up part wear. Additionally, they can lead to imbalances, putting more stress on bearings and gears, which further increases energy consumption and wear.

Tilting moments can be dangerous because they might cause machines to break down, lead to accidents, or make the equipment wear out faster. To keep things safe and running smoothly, it's important to:

- Keep an eye on the machinery with real-time monitoring.

- Regularly inspect and maintain the equipment.

- Design the equipment to manage these forces effectively.

How to Mitigate Tilting Moments

Proper Bearing Selection

When choosing slewing bearings for high tilting moments, consider factors like load capacity, rigidity, and material strength. For heavy-duty applications, opt for cross roller bearings excel because they are better in rigidity and load distribution. In contrast, four-point contact bearings good at staying steady even when things aren't perfectly lined up and under varying loads. Choose the right bearings for your needs so your machinery works well and lasts longer.

Structural Considerations

Making the structure around the machinery really matters for reducing those tilting moments. It helps keep the parts in good shape and extend equipment life. Good design means balanced load distribution, precise alignment to ensure forces act centrally, and the incorporation of self-aligning mechanisms that can fix themselves if things get a little off-kilter. Making the structure strong and adding extra support also helps counteract tilting forces, enhancing overall stability and efficiency.

Maintenance and Monitoring

To keep slewing bearings from getting too much tilting stress, follow these steps and use the monitoring methods listed:

Maintenance Practices:

- Regular Inspections: Inspect for any visible damage, rust, or if things are not aligned properly.

- Vibration Analysis: Look out for unusual vibrations which might signal problems.

- Lubrication: Maintain proper lubrication to reduce friction and heat.

- Load Assessment: Make sure loads are within specified limits to prevent overloading.

- Alignment Checks: Check that everything is aligned properly to spread the load out evenly.

- Cleaning: Maintain the cleanliness of the bearing by ensuring it is free from debris.

- Seal Replacement: Ensure the timely replacement of seals that are worn or damaged.

- Record Keeping: Keep a record of all maintenance work for future reference.

Monitoring Techniques:

- Sensors: Use devices like accelerometers and strain gauges to monitor the condition in real time.

- Condition Monitoring Systems: Analyze sensor data and get a heads-up on what might happen next.

- Torque Sensors: Measure actual loads to compare against design limits.

- Thermal Imaging: overheating areas due to friction or misalignment.

- Data Logging: Keep track of how things work over time to analyze the trend.

- Predictive Maintenance Software: Employ machine learning to forecast maintenance needs.

Case Studies

Case Study 1: Construction Equipment

Cranes and excavators can have tilting moments because of dynamic and uneven loads. This might lead to potential misalignment and structural stress. To handle these issues, try these solutions:

- Use High-Capacity Bearings: Opt for robust designs like crossed roller or four-point contact ball bearings to handle higher loads.

- Regular Maintenance: Schedule frequent inspections and lubrication to maintain bearing performance and reduce wear.

- Load Management: Use systems that monitor and adjust load distribution to minimize tilting effects.

- Structural Reinforcement: Strengthen the boom or arm to increase rigidity against tilting moments.

- Advanced Materials: Use materials that can handle more wear and tear, and that can carry heavier loads.

- Real-time Monitoring: Install sensors to track loads and bearing health to make it easy to take immediate corrective actions.

- Operator Training: Teach operators how to manage loads correctly and use the equipment properly, so they can avoid too much tilting.

- Design Optimization: To reduce tilting moments, make sure the equipment is designed just for the jobs and situations it will be used in.

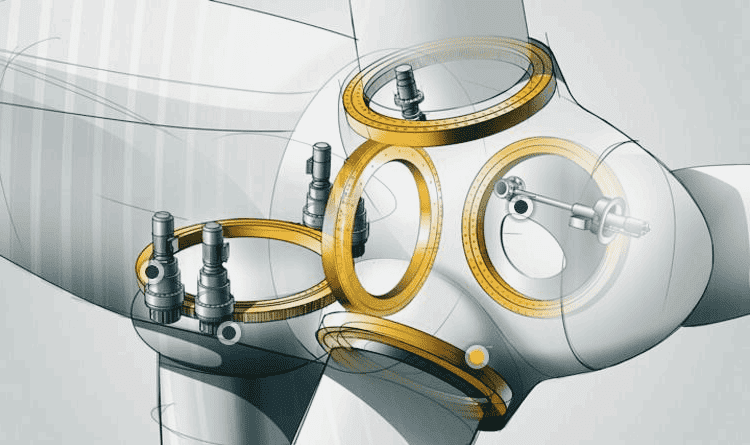

Case Study 2: Wind Turbines

In wind turbines, tilting moments in slewing bearings are caused by uneven wind-related and gravitational forces. These moments can reduce bearing life and turbine efficiency. The wind energy sector addresses this issue with strategies such as:

- Advanced Bearing Design: Choose special bearings that can handle higher load.

- Load Balancing: Implement active pitch control to equalize forces on blades.

- Structural Design: Make sure the turbine's structure is strong enough to resist tilting moments.

- Real-time Monitoring: Use sensors to automatically adjust for changing loads.

- Regular Maintenance: Perform frequent inspections to identify and address issues before they get worse.

- Dampers: Employ damping systems to soak up the energy from tilting moments.

- Operator Training: Train operators to run the turbine correctly to reduce tilting moments.

- Ongoing R&D: Invest in research for improved materials and designs to better handle these forces.

Conclusion

Understanding how to handle tilting moments in slewing bearings is of great importance. It helps to improve functionality, safety, and longevity. At LILY Bearing, we encourage our customers to consider tilting moments during the planning and maintenance phases of their equipment. For specialized solutions or expert advice, reach out to LILY Bearing — your go-to for top-notch bearings.

Keep Learning