What is the Torque of a Slewing Bearing?

Slewing bearings play a key role in many industries. They allow things to rotate while also handling different types of loads. One important part of these bearings is the torque, which is what makes them function efficiently. This article will explain what torque means, what can change it, how to calculate it, and where it's used in slewing bearings.

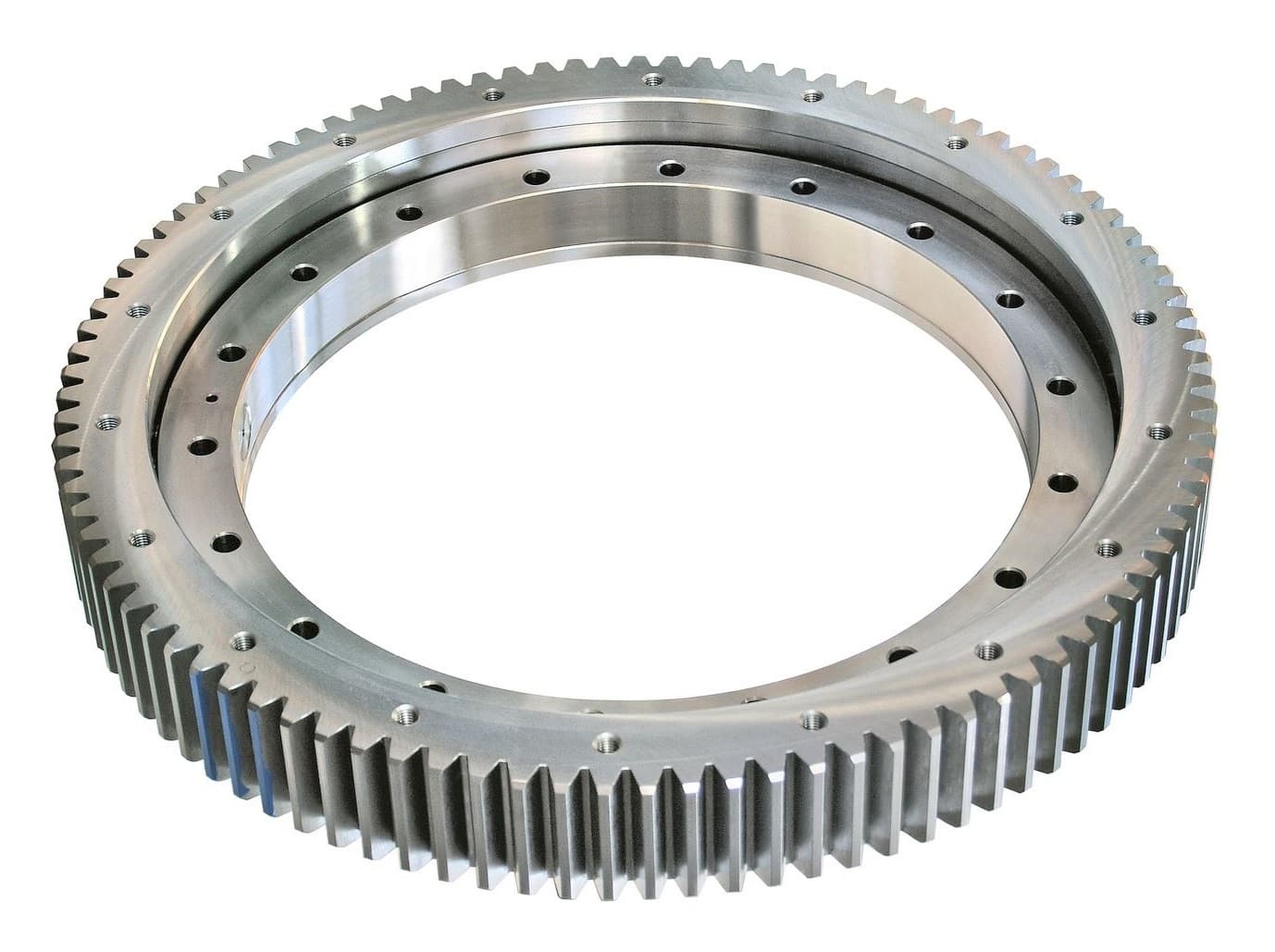

Understanding Slewing Bearings

Slewing bearings, also called turntable bearings or slewing rings, are large-sized bearings designed to handle high loads. They help things spin around and often play a role in cranes, wind turbines, and all kinds of big machines. These bearings are great at supporting heavy loads and allowing smooth rotational motion.

Components of Slewing Bearings

Key components of slewing bearings have different roles in torque management.

Table 1 Key components of slewing bearings and their roles in torque management

|

Component |

Function |

Role in Torque Management |

|

Inner Ring |

Provides a raceway for the rolling elements and is attached to the rotating part. |

Transfers the twisting force to the rest of the bearing when torque is applied. |

|

Outer Ring |

Provides a raceway and is fixed to the stationary part. |

Supports the inner ring and ensures smooth rotation. |

|

Rolling Elements |

Balls or rollers that facilitate smooth rotation and handle load distribution. |

Reduce friction and spread out the torque, helping the bearing handle the load more effectively. |

|

Cages/Spacers |

Maintain the proper spacing and alignment of the rolling elements. |

Ensure the rolling elements are evenly spaced and aligned, contributing to the bearing's efficiency and longevity. |

What is Torque?

Torque is the rotational equivalent of linear force. It is a measure of the force that can cause an object to rotate about an axis.

In simple terms, torque (τ) is calculated by multiplying the rotational force (F) by the distance (r) from the point where the force is applied to the axis of rotation. The formula for this is τ = F × r.

Importance of Torque in Slewing Bearings

Torque is critical for slewing bearings. It directly affects their performance and efficiency. Proper torque ensures smooth rotational motion, reduces wear and tear, and enhances the bearing's lifespan. If there's not enough torque or too much torque, it can cause problems and might even break the bearing.

Factors Affecting Torque in Slewing Bearings

Load Types and Distribution

The types of loads that impact the torque on a slewing bearing include:

- Axial Loads: Forces applied parallel to the axis of rotation.

- Radial Loads: Forces that are directed straight out from the axis.

- Moment Loads: Twisting forces that create torque around the axis.

The distribution of loads and their weight significantly affect the amount of torque a bearing needs to work at its best. Axial loads, which are pushing or pulling straight in, make the bearing's friction torque change. Radial loads, which are sideways pressures, change the stress inside the bearing. Tilting moments, like when something is leaning, can affect how long the bearing lasts because they change where the pressure is.

Friction and Lubrication

Friction plays a crucial role in torque generation. Proper lubrication reduces friction, thereby optimizing torque and ensuring smooth operation. But if there's not enough lubrication, slewing bearing get harder to move and can even suffer damage.

Table 2 Key benefits of proper lubrication for slewing bearings

|

Importance Aspect |

Description |

|

Reduces Friction |

Lubrication creates a smooth layer, reducing resistance between moving parts. |

|

Optimizes Torque |

Less friction means the bearing can use available torque more efficiently. |

|

Protects Components |

Lubrication shields metal parts from rubbing against each other, reducing wear. |

|

Extends Lifespan |

By reducing wear, lubrication helps the bearing last longer. |

|

Improves Performance |

A well-lubricated bearing handles loads and torque more effectively, enhancing overall machine efficiency. |

Bearing Design and Materials

A slewing bearing's design and the materials used significantly affect how efficiently it handles torque. Good quality materials and exact engineering make for a bearing that gives you a smoother torque performance. Checking out various materials can help you choose the right one for different jobs.

Table 3 Comparison of different slewing bearing materials

|

Material |

Characteristics |

Advantages |

Disadvantages |

|

Bearing Steel |

High hardness, wear resistance, fatigue strength |

Long service life under high load and speed |

Poor in corrosive environments |

|

Ceramic Materials |

High hardness, lightweight, high-temperature resistance |

Low friction at high speeds, excellent in high-temperature environments |

Brittle, high cost |

|

Stainless Steel |

Corrosion and heat resistance |

Suitable for humid or corrosive environments |

Not as hard or wear-resistant as bearing steel |

|

Plastic/Polymer |

Lightweight, self-lubricating, corrosion-resistant |

Good for low-load, low-speed applications |

Not suitable for high-load, high-speed applications |

|

Bronze |

Good wear resistance, suitable for moderate loads |

Can withstand vibrations and impacts |

Requires regular lubrication |

Installation and Alignment

Correct installation and alignment are vital for optimal torque performance. Misalignment or improper installation can lead to uneven load distribution, increasing torque requirements and causing premature wear.

Table 4 The impact of common installation issues on torque of slewing bearings

|

Installation Issue |

Impact on Torque Efficiency |

|

Surface Flatness |

Misalignment, increased friction and wear |

|

Preload Setting |

Uneven load distribution, increased friction |

|

Bolt Torquing |

Binding or looseness, affecting torque transmission |

|

Lubrication |

Overheating and premature wear, reduced efficiency |

|

Storage and Handling |

Damage or dirt, performance issues |

|

Seal Integrity |

Contaminant ingress, increased friction |

|

Post-Installation Inspection |

Potential issues with functioning if not thorough |

|

Hardness Matching |

Ensures effective torque transmission and reduced wear |

|

Cleaning |

Prevents performance decline from residue |

|

Installation Direction |

Proper orientation for even load distribution |

Calculating Torque for Slewing Bearings

Basic Torque Calculation Formula

Calculating slewing bearing torque isn't straightforward because of various influencing factors like design, loads, and materials. However, general formulas based on physical principles can provide estimates. These include formulas based on power, moment of inertia, and force multiplied by distance.

1. Torque equals power divided by angular velocity: M=P/ω

Where:

- M is the torque (usually in newton meters).

- P represents the power (in watts).

- ω is the angular velocity (in radians per second).

2. Torque equals moment of inertia multiplied by the speed at which a slewing bearing rotation speed changes: M=Jα

Where:

- J is the moment of inertia (in kilogram meters squared).

- α is the speed at which the bearing rotation speed changes. (in radians per second squared).

3. Torque equals force multiplied by the lever arm: M=F×L

Where:

- F is the applied force (in newtons).

- Apply the force at a distance from the pivot point, which is represented by L in meter

For slewing bearings, the following factors may also need to be considered:

- The geometric parameters and material properties of the bearing.

- The friction coefficient within the bearing.

- The combined loads borne by the bearing, including axial, radial, and overturning moments.

- The preload of the bearing and installation errors.

Example Calculation

Suppose we have a crane that needs to rotate its jib 360 degrees. Here are the steps to calculate the torque required for the slewing bearing to perform this task.

Step 1: Define the Parameters

First, we need to define the parameters for our calculation. Let's assume the following:

- The crane's jib has a mass of 5000 kg.

- The center of mass of the jib is at a radius of 10 meters from the bearing.

- The crane operates at a rotational speed of 0.2 radians per second (which is a slow, controlled speed).

- The bearing has an efficiency (η) of 0.9 (indicating 90% of the input power goes into rotation, with the rest lost to friction).

- The power (P) required to rotate the jib is provided by the crane's motor and is 10 kW.

Step 2: Calculate the Moment of Inertia

The moment of inertia (J) for a point mass is given by J=m×r2, where mm is the mass and r is the radius.

For the jib, we have: J=5000kg×(10m)2=500,000kg⋅m2

Step 3: Calculate the Rate at which the Angle Changes over Time.

Since the crane is rotating at a constant speed, the rate at which the angle changes over time, or angular acceleration (α), is zero (because the speed is not changing).

However, if we were starting from rest and speeding up, we would calculate α with the formula α=Δt/Δω, where Δω is the change in angular velocity and Δt is the time over which the change occurs.

Step 4: Calculate the Torque Using Power and Angular Velocity

We can use the formula M= P/ω to calculate the torque. First, we need to express the power in watts and the angular velocity in radians per second:

P=10 kW=10,000 W

ω=0.2 rad/s

M = 10,000 (W)/ 0.2 (rad/s) = =50,000 Nm

Step 5: Adjust for Efficiency

Since not all of the input power goes into rotation (due to losses), we adjust the torque for the bearing's efficiency:

Mactual=M×η=50,000Nm×0.9=45,000Nm

Step 6: Consider Additional Loads

In real-life situations, we may have to think about extra loads like wind or moving things on a crane. These add to the twisting force needed and can be determined using similar mathematical principles. This involves considering the force applied and the distance from the bearing.

Advanced Considerations

For complex applications, we may need to take into account extra factors like dynamic loads, temperature changes, and the operating speed of the slewing bearings. Software tools can assist in accurate torque calculations by:

- Modeling dynamic load effects.

- Simulating temperature impacts.

- Analyzing various running speeds.

- Verifying proper mounting and alignment.

- Addressing the requirements for lubrication.

- Considering environmental factors.

- Forecasting material fatigue.

- Tailoring bearing design.

- Analyzing load distribution.

- Accounting for manufacturing tolerances.

Applications of Slewing Bearings and Torque

Industrial Machinery

Slewing bearings are critical in industrial machines for their ability to support complex loads and enable smooth rotation. Torque is a crucial factor as it affects how smoothly slewing bearings work and how long the machines last. Proper calculation and management of torque is what makes machines with slewing bearings work well and dependably.

Construction Equipment

In construction equipment like cranes and excavators, slewing bearings play a vital role. In cranes, slewing bearings allow the entire crane body or jib to rotate a full 360 degrees. For excavators, these bearings enable the upper structure, which includes the excavating arm, to rotate relative to the base.

Torque enables the machines to handle heavy loads and perform complex maneuvers. As a result, torque is critical for the precise and safe operation of them.

Renewable Energy

Slewing bearings are super important in wind turbines and solar trackers. They make sure that these machines can twist and turn just right, which helps them work better and last longer.

In wind turbines, you need a good amount of torque to spin the large blades and generate electricity. The gears in wind turbines must be precisely calibrated so that they can change the speed from the slow turning of the blades to the faster spinning of the generator. This is where torque plays a pivotal role – it can be compared to the force that initiates motion.

For solar trackers, they use torque to follow the sun across the sky. The more precisely they can move, the more sunlight they can catch, and the more electricity they can make. That's why the amount of torque they need is so important.

Ensuring Optimal Torque Performance

Regular Maintenance and Inspection

Regular maintenance is essential to ensure proper torque performance.

Maintenance Tips for Slewing Bearings:

1. Visual Inspection: Look for any signs of wear, cracks, or damage. Check for proper alignment and make sure the bearing is clean.

2. Lubrication Check: Ensure that the bearing is adequately lubricated to maintain optimal performance. Over or under-lubrication can affect torque and lead to premature bearing failure.

3. Listen for Noise: Unusual sounds can signal the presence of problems. A well-maintained bearing should run smoothly and quietly.

4. Inspect for Movement: Ensure the bearing has no excessive movement or instability. This could indicate a problem with the mounting or the bearing itself.

5. Temperature Monitoring: Bearings that are working too hard can get hot. Keep an eye on temperature to catch issues early.

6. Vibration Analysis: For better maintenance, using vibration analysis can help find and fix problems before they get worse.

The frequency of maintenance can depend on the specific application and the manufacturer's recommendations. It's always a good idea to follow the guidelines provided with the bearing and to tailor your maintenance schedule based on how heavily the equipment is used and the operating conditions.

Upgrading and Replacing Components

Slewing bearings may need upgrades or replacements because of the following reasons:

1. Wear and Tear: Over time, parts can wear down, reducing torque efficiency.

2. Exceeding Loads: Consistently bearing too much weight can cause early failure.

3. Lubrication Issues: Poor lubrication increases friction and heat, leading to potential replacement.

4. Environmental Factors: Harsh conditions like extreme temperatures or corrosives can damage the bearing.

5. Fatigue and Cracking: Repeated stress can cause cracks and the need for replacement.

6. Technological Advances: Newer designs may offer better performance.

7. Maintenance Findings: Regular checks might uncover issues requiring repair or replacement.

8. Performance Drop: Increased vibration or noise can signal bearing problems.

9. Age: Bearings have a limited lifespan and may need replacement over time.

10. Changing Requirements: If the demands on the equipment evolve, bearings may need upgrading.

Signs of lubrication failure indicating a need for bearing upgrade include:

1. Excessive Heat: Suggests inadequate friction reduction.

2. Unusual Noises: Indicates metal-on-metal contact because of poor lubrication.

3. Increased Vibration: Can result from poor rotational smoothness.

4. Rust or Corrosion: Lack of lubrication makes bearings vulnerable.

5. Visible Wear: Flaking or pitting can indicate insufficient lubrication.

6. Leakage: Grease or oil leaks suggest the bearing isn't retaining lubricant.

7. Inconsistent Performance: Erratic operation or reduced efficiency can signal lubrication problems.

8. Frequent Servicing: Increased maintenance could be a sign of problems with lubrication.

Regular maintenance and timely component replacement are essential for optimal torque performance and reliable machinery operation.

Conclusion

To keep slewing bearings running their best, it's important to know how to handle torque. For smooth and dependable operation, consider the types of loads, friction levels, bearing design, and making sure it's installed right. Keeping up with maintenance and upgrading parts when needed will also ensure torque performance in various applications.

Keep Learning