Where Are One Way Bearings Used?

One way bearings, also known as overrunning clutches, are essential in many modern industries. They provide reliable one way operation and preventing unwanted reverse motion. In this blog, we will explore “where are one way bearings used” and discuss how these bearings enhance efficiency, reliability, and performance across different sectors.

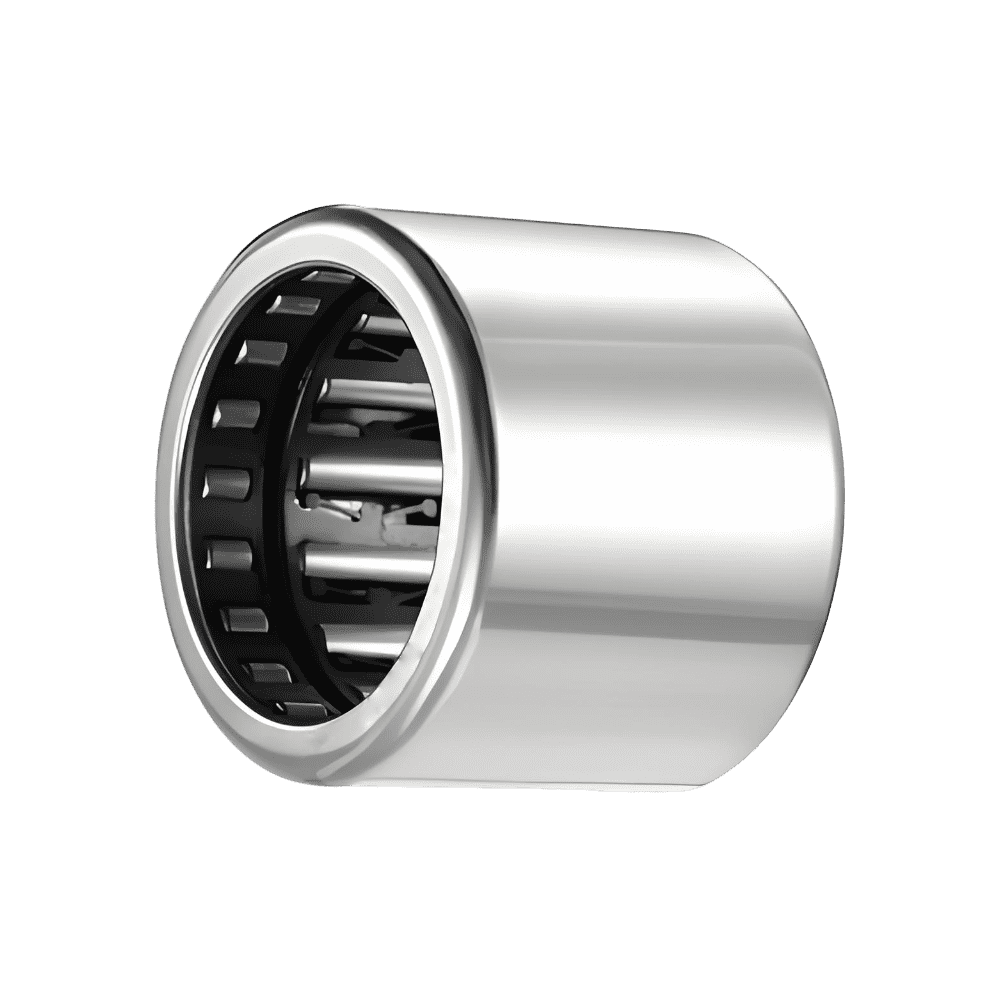

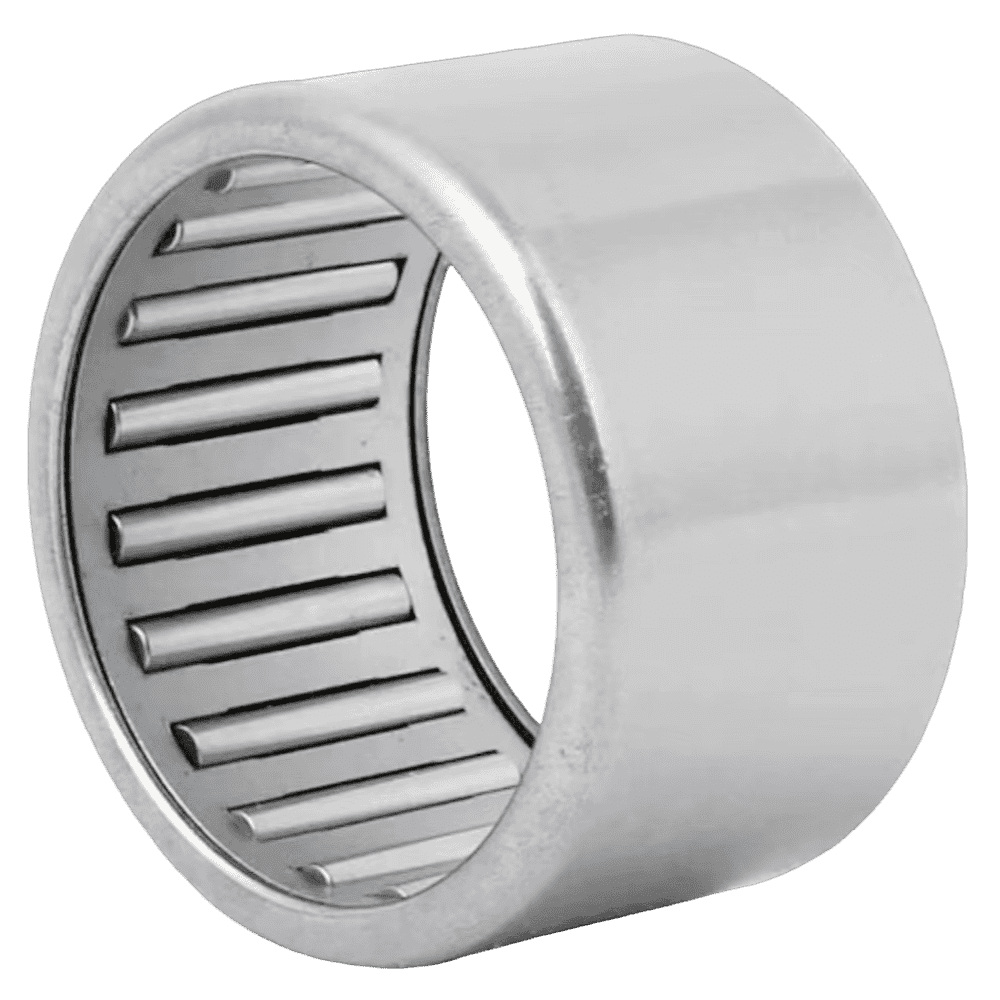

Understanding One Way Bearings

One way bearings, are special mechanical parts. They allow rotation in one direction while preventing it in the opposite direction. These sprag clutch bearings have an inner ring, an outer ring, and rolling elements. They also include a mechanism that allows rotation in one direction while stopping it in the other.

Working Principle of One Way Bearings

The working principle of one way bearings is quite unique. They can allow rotation in one direction while preventing motion in the opposite direction. Typically, the metal shell of a one way bearing contains either needle rollers or sprags.

The shape of its rolling seat (hole) allows it to roll in only one direction. It produces great resistance in the other direction, following the so-called "one-way" principle. Here’s a detailed explanation of their working principle:

- Engagement Mechanism: One way bearings have a cam or wedge mechanism inside them. When the bearing rotates in the allowed direction, the rolling elements move freely. This allows the bearing to operate like a normal bearing with minimal resistance. This smooth movement ensures efficient performance. It also reduces wear and tear on the bearing.

- Locking Mechanism: When the bearings try to rotate in the opposite direction, the rolling elements are forced against the cam. This creates a wedge mechanism, and creates a wedging effect, causing the rolling elements to lock against the inner and outer rings.

Key Features of One Way Bearings

One way bearings allow components to engage or disengage automatically based on the direction of rotation. Here are the key features and functions:

- Unidirectional Operation: These one way needle roller bearings allow free rotation in one direction and locks in the opposite direction.

- Increased Load Capacity: One way bearings transmit torque in the desired direction and handle high loads effectively. They are used in applications such as gearboxes and electric starters.

- Durability: These one way needle bearings are designed for long-lasting operation with minimal maintenance.

- Compact Design: The compact size of these clutch bearings makes them particularly well-suited for applications where space is limited, allowing for efficient integration into tightly constrained environments without compromising performance.

Benefits of One Way Bearings

- Reliability: Their robust design requires minimal maintenance, reducing downtime and operating costs.

- Improved Efficiency: One way bearings reduce energy consumption, especially in systems like conveyor belts and bicycles.

- High Torque Transmission: Sprag clutch bearings transmit torque in the desired direction, making them suitable for high-load applications.

- Safety Enhancement: These bearings contribute to the safety of mechanical systems by preventing unintended reverse movements. This is particularly important in applications like elevators, winches, and automotive systems.

- Low Maintenance: Simplify the mechanical design of the equipment, reducing the number of components that can fail.

- Extended Lifespan: One way bearings allow freewheeling and prevent reverse motion, reducing wear and tear on components. This helps to extend their lifespan and maintain efficient operation.

Common Applications of One Way Bearings

One way bearings are used in many different industries. For example, in conveyor systems, one way bearings can prevent equipment from rotating in the opposite direction. In some mechanical structures that require one way rotation, one way bearings play an important supporting role. In addition, one way bearings are often used in wheel hubs of cars and other vehicles to ensure the normal operation of tires.

The bearings significantly improve performance and reliability across various sectors by ensuring one way motion, preventing reverse rotation, and reducing mechanical stress.

Automotive Industry

- Automatic Transmissions: One way bearings enhance the overall driving experience by facilitating smooth gear shifts. They also allow components to freewheel.

- Starter Motors: One way clutch bearings are very useful in starter motors, because they allow the motor to disengage smoothly once the engine has started. This prevents the motor from carrying any unnecessary load, which helps it run more efficiently and last longer.

Industrial Machinery

- Conveyor Systems: Clutch one way bearings prevent reverse motion that could cause jams or damage. This helps to reduce downtime and lower maintenance requirements.

- Pumps and Compressors: One way sprag clutches play a crucial role in the performance and reliability of pumps and compressors. They allow shafts to rotate in a single direction.

Printing Equipment

- Paper Feed Mechanisms: Control the movement of paper to ensure it only moves in the correct direction.

Exercise Equipment

- Treadmills and Ellipticals: One way bearings are useful components in treadmills and ellipticals, ensuring safe and smooth operation.

Bicycles

- Freewheel Mechanisms: One way roller clutches enable the rear wheel to spin freely when the rider is not pedaling. This provides a smooth and effortless coasting experience.

Specialized Applications of One Way Bearings

One way bearings contribute to advancements in technology, ensuring the smooth operation of complex systems in specialized applications.

- Aerospace Industry: These bearings are crucial for the operation of satellite systems. They ensure a continuous power supply and functionality in space.

- Medical Devices: One way bearings are used in dialysis machines to ensure blood flows in the correct direction.

- Renewable Energy Systems: One way bearings protect turbines from damage caused by sudden wind shifts, which helps to reduce repair costs and minimize downtime.

Conclusion

One way bearings are important in various industries. Their contribution to the performance and durability of mechanical systems makes them Key in modern engineering and technology.

For top-quality one way bearings and expert guidance, trust LILY Bearing to provide the best solutions for your needs. Explore our extensive range of bearings to improve the performance and extend the lifespan of your machinery.

Keep Learning