Exploring the Advantages of High-Quality Dental Bearings

CONTENTS

Dental bearings, though small, are vital in dental handpieces, crucial for effective and efficient procedures. These bearings offer significant impact in dental practice, whether they are ceramic bearings or hybrid. High-quality dental bearings deliver optimal performance at high speeds, require no maintenance, and ensure successful dental treatments. In this article, we explore the advantages of dental bearings.

The Role of Dental Bearings

Dental handpieces, often referred to as dental drills, are precision instruments that operate at high speeds. They are used in a variety of procedures, from removing decay and polishing fillings to cutting through bone. The bearings inside these handpieces make the turbine rotate smoothly. This ensures reliable and precise motion for delicate dental work.

Why Bearing Quality Matters

Precision is crucial in dental procedures. The use of high-quality dental bearings is essential for maintaining the accuracy and effectiveness of a dental handpiece. Low-quality bearings can cause more vibration, noise, and less precise operation, negatively impacting patient comfort and procedure results.

Advantages of Ceramic and Steel Bearings

Dental bearings can be made from a variety of materials, including stainless steel, ceramic, and combinations of both. We will examine the advantages of each type.

Ceramic Bearings: Precision at High Speeds

Ceramic bearings, typically made from silicon nitride, are renowned for their ability to handle high speeds with ease. They are lighter than steel, reducing centrifugal forces and allowing faster rotation without extra stress on the handpiece's motor. Additionally, ceramic bearings produce less heat because of their low friction, keeping the handpiece cool during long use.

Hybrid Bearings: The Best of Both Worlds

Hybrid ceramic bearings combine ceramic balls with stainless steel inner and outer rings. This combination harnesses the strength of steel with the low friction and lightweight properties of ceramic. The result is a bearing that can sustain high speeds while offering a robust and durable solution.

Stainless Steel Bearings: Affordable and Reliable

Stainless steel bearings are a more traditional option in dental handpieces. They are less expensive than their ceramic counterparts and can offer a reliable performance for dental professionals. However, they may not match the speed and reduced friction benefits of ceramic or hybrid bearings.

Types of Dental Bearings

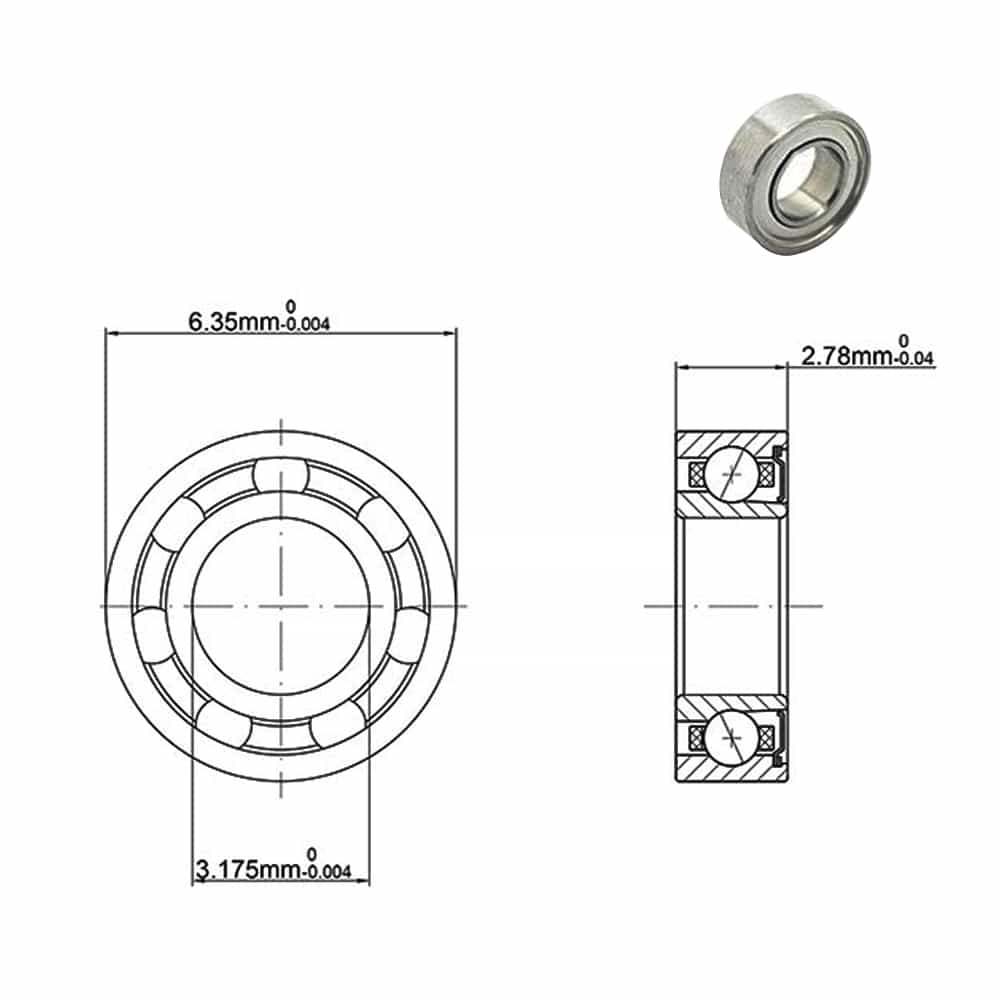

Dental bearings are crucial for ensuring smooth, precise, and reliable operation of dental handpieces. Below are the various types of dental bearings available:

- Provide low friction and quiet operation.

- Versatile with a range of bore diameters, outer diameters, and widths.

- Available in angular contact and radial ball bearing types.

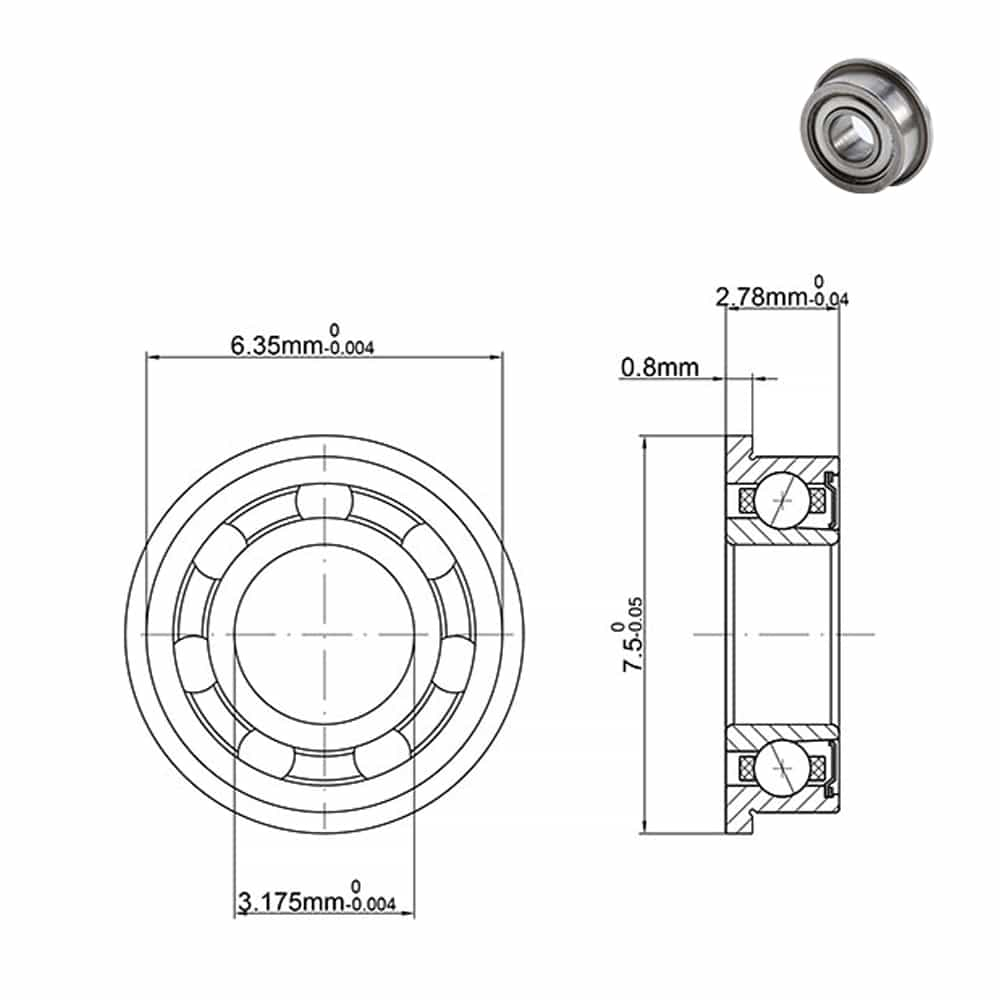

- Feature a flange for secure positioning and reliable support.

- Ideal for handling radial and axial loads during high-speed operations.

- Made from high-quality materials like Silicon Nitride (Si3N4) and stainless steel.

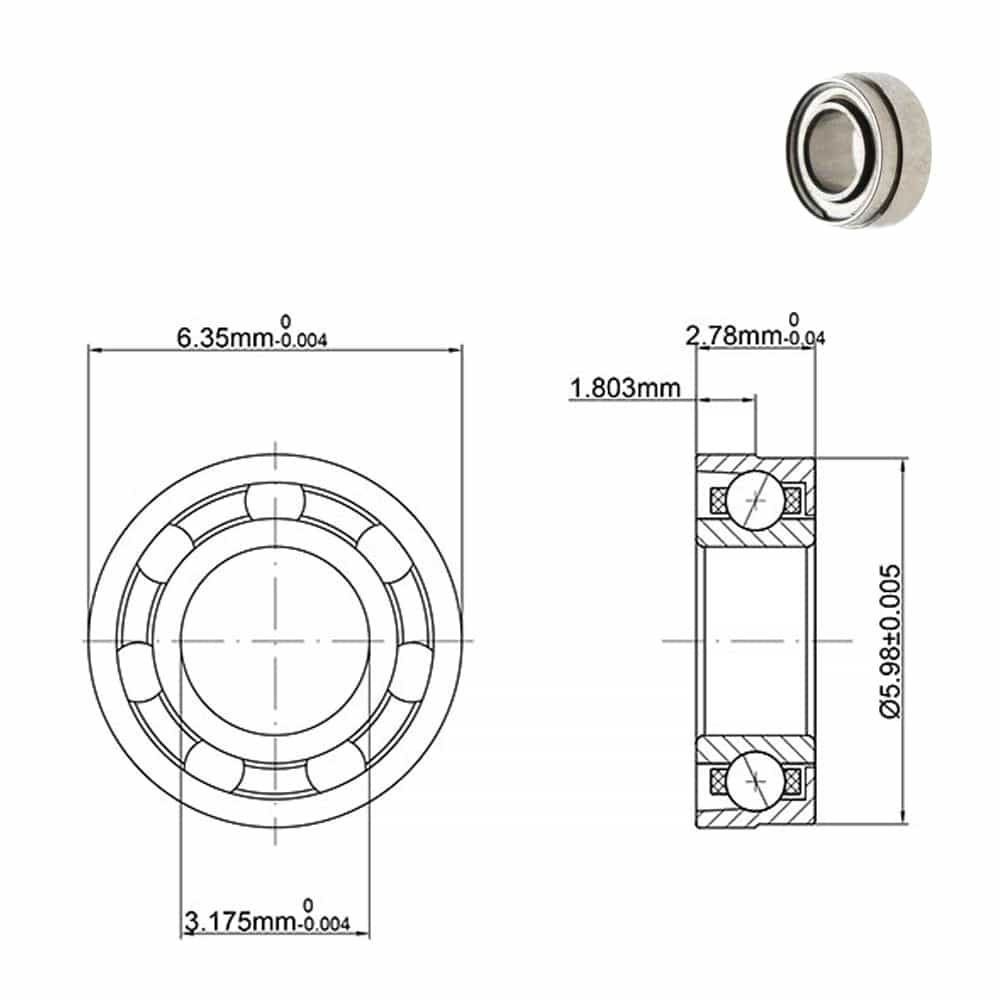

- Designed with multiple diameter sections for precise alignment and support.

- Ensure secure fitting within the handpiece, reducing misalignment risks.

- Available in angular contact and radial types, made from durable materials.

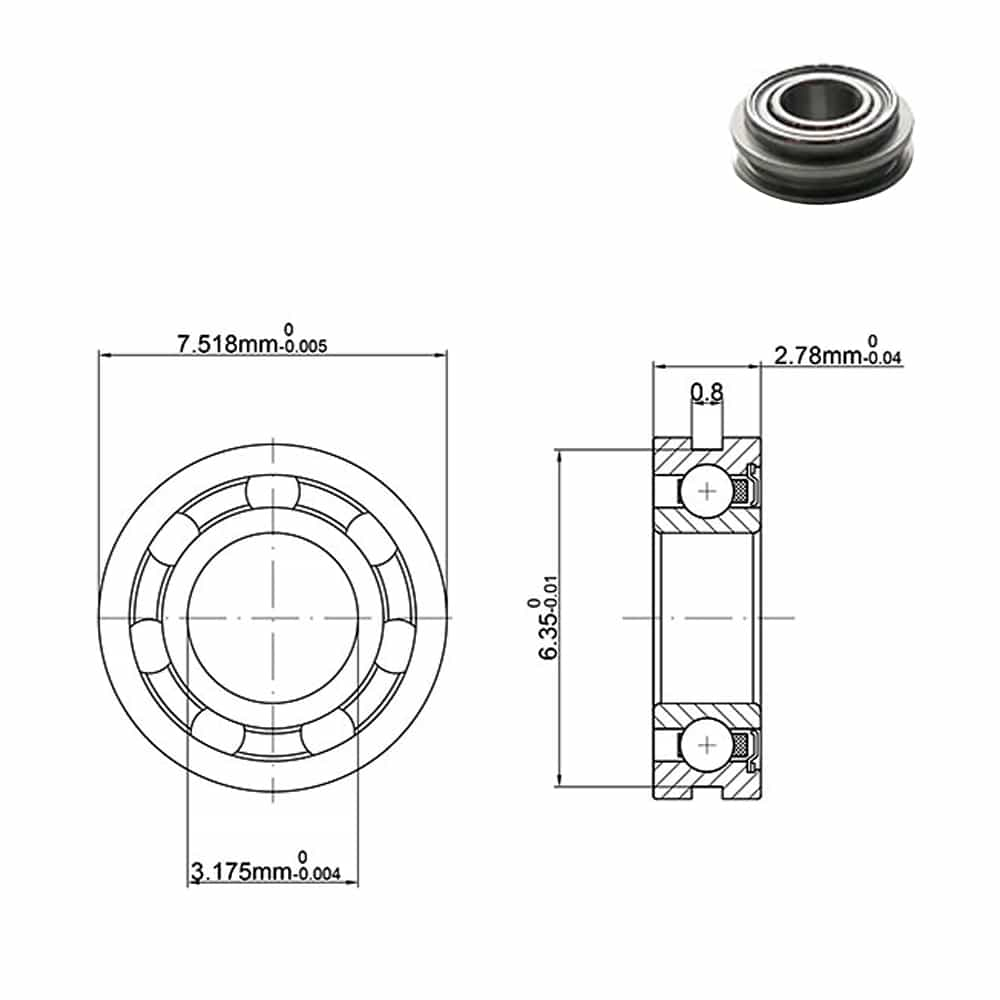

- Offer specialized designs and tailored solutions for specific dental applications.

- Enhance performance in demanding situations where standard bearings may not suffice.

- Crafted to meet unique size requirements and specialized sealing needs.

The Impact of Ceramic and Steel Balls in Dental Bearings

The choice between ceramic balls and steel balls within the bearing can significantly impact the handpiece's performance.

Ceramic Balls: Reduced Vibration and Noise

Ceramic balls are much smoother and harder than steel balls, which leads to reduced vibration and lower operating noise. This increased smoothness also reduces the risk of bearing failure, as there is less wear on the balls and the bearing races.

Steel Ball Bearings: A Cost-Effective Option

Steel ball bearings are a cost-effective choice and can perform adequately for many dental procedures. They are easy to find and are a good choice for dental practices that need to balance performance and budget.

Maintenance and Durability of Dental Bearings

Maintenance-Free Operation

High-quality dental bearings have a major advantage. They are often maintenance-free, especially ceramic and hybrid types. This is because of their resistance to corrosion and the ability to operate without lubrication. The result is less downtime for maintenance and longer intervals between bearing replacements.

Longevity and Resistance to Debris

Dental procedures often produce debris that can infiltrate the components of a dental handpiece. High-quality dental bearings resist debris. This prolongs their lifespan and keeps the handpiece in good condition.

Bearing Failure: Understanding the Risks

Bearing failure can result from several factors, including poor maintenance, excessive loads, and dirt. Use high-quality bearings to reduce these risks. Follow the manufacturer's maintenance guidelines. This ensures a long term service life for the dental handpiece.

The Importance of Choosing the Right Dental Bearings

Ensuring Optimal Performance

Choosing the right type of bearing is crucial for dental professionals who rely on their handpieces to perform at their best. Understanding the advantages of ceramic, hybrid, and stainless steel bearings is essential. This helps dental professionals make informed decisions for optimal performance during procedures.

Factors to Consider

When selecting dental bearings, consider operating speeds, load capacities, resistance to corrosion and debris, and overall quality. Dental professionals should also weigh the costs against the expected lifespan and performance benefits of the bearings they choose.

Types of Bearings for Different Dental Procedures

Different dental procedures may require varying levels of precision and speed. Choose the type of bearing in a dental handpiece based on the specific needs of the procedure.

High-Speed Applications

Ceramic or hybrid bearings are best for high-speed procedures like cavity preparation. They perform well at elevated speeds.

Low-Speed Applications

For low-speed applications, such as polishing or endodontic work, stainless steel bearings may suffice. These procedures don't need high speed or precision. This allows for a more economical bearing choice.

Conclusion: The Benefits of Investing in Quality Dental Bearings

In conclusion, the advantages of dental bearings—particularly ceramic and hybrid varieties—are clear. They reduce vibration, require no maintenance, and handle high speeds, enhancing dental procedure precision and effectiveness. For dental professionals, investing in high-quality bearings is crucial. With the right bearings, dental handpieces can perform at their peak, ensuring patient comfort and optimal outcomes.

In the end, the choice of dental bearings comes down to a balance of cost, performance, and the specific needs of the dental practice. Whether ceramic, hybrid, or stainless steel, each type of bearing has its place in the dental industry. By knowing the benefits of each type, dental professionals can choose handpieces that offer the best patient care.

Keep Learning