How to Choose the Right Cam Follower for Your Application

Selecting the right cam follower is crucial for the optimal performance and longevity of your mechanical systems. This blog will help you easily understand the important factors to consider, choices of materials and design, and a straightforward way to select the best options for top performance. We’ll also provide case studies and examples, and introduce some well-known brands in the industry.

Understanding Cam Followers

A cam follower, also known as a roller bearing, is a special kind of bearing. It follows the shape of a cam to change spinning movement into straight-line movement. They play a critical role in reducing friction and ensuring smooth operation in wide ranges of mechanical systems.

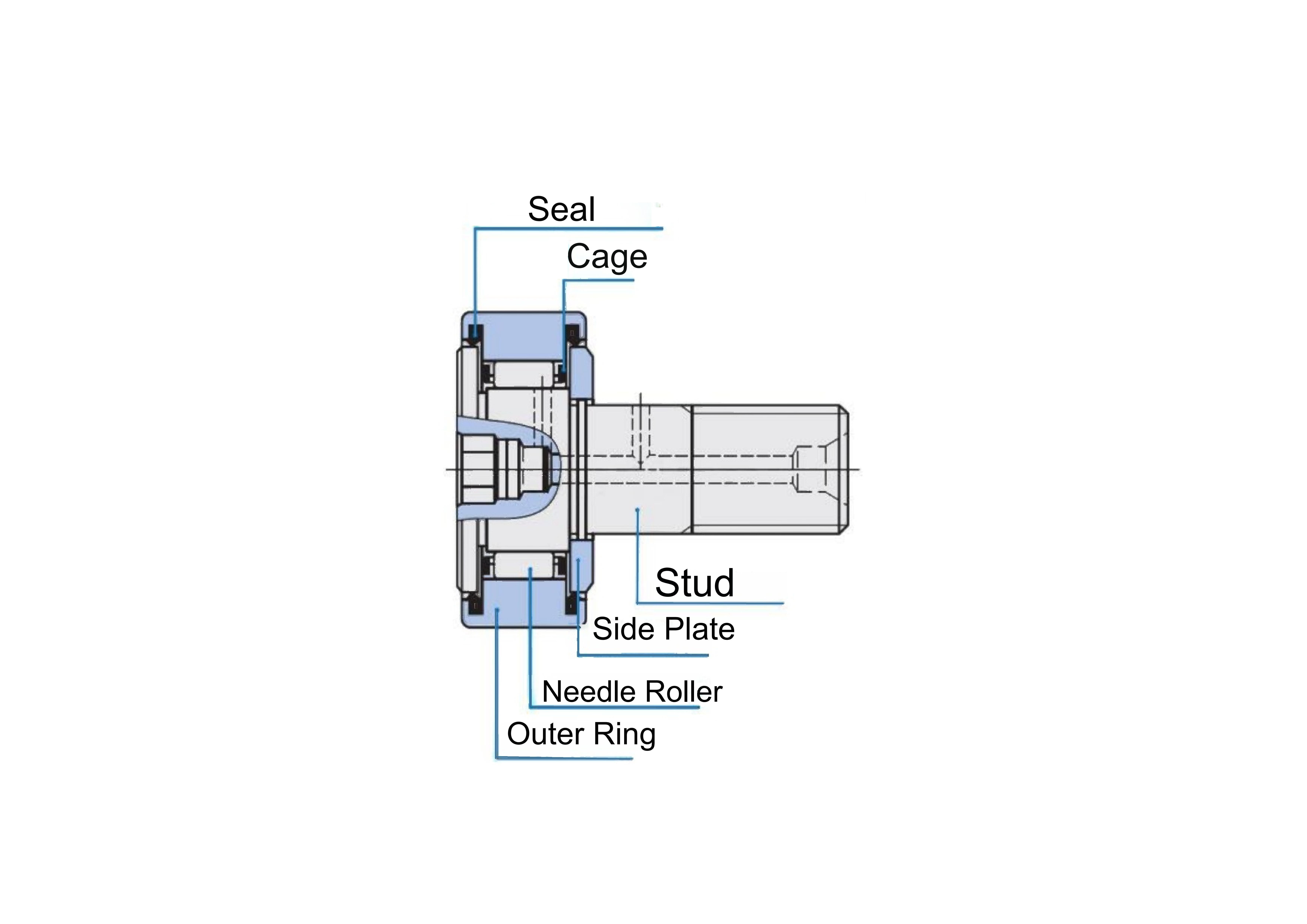

Structure of Cam Follower Bearings

Cam followers include several key components:

- Outer Ring: The rolls along the cam's side, reducing friction efficiently with its possibly crowned outer rings for the best performance.

- Stud/Yoke: The mounting component that attaches the cam follower to the machinery.

- Rolling Elements: Balls, rollers, or needle bearings that facilitate smooth rotation. Ball bearing options provide precision and durability.

- Seals: Protect internal components from contaminants and retain lubrication.

- Side Plate: Holds rolling elements in place, ensuring even load distribution.

- Cage: Directs rollers, reduces friction, and supports even load carrying.

Types of Cam Followers

- Stud Type: A stud type cam follower features a threaded stud for secure fastening. Ideal for applications requiring straightforward installation.

- Yoke Type: A yoke type cam follower comes with a central hole for versatile mounting, making it suitable for various motion systems.

Key Factors to Consider When Choosing a Cam Follower

Load Capacity

Picking a cam follower that can handle the right amount of weight is key to avoid breakdowns and make your equipment last longer.

Speed and Performance

The operating speed of your motion systems significantly impacts the selection of cam followers. Ball bearing options might be best for high-speed applications.

Environmental Conditions

Select cam followers designed to withstand your operating environment, considering factors like temperature and exposure to dirt.

Material and Design

Material Choices

The table below will make it easy for you to compare the various material options for cam followers, showing their strengths, weaknesses, and when they're best used:

|

Material |

Strengths |

Weaknesses |

Best For |

|

Carbon Steel |

High strength and durability, cost-effective |

Susceptible to corrosion if not properly treated or lubricated |

General-purpose applications where cost is significant, and environmental conditions are mild |

|

Stainless Steel |

Excellent corrosion resistance, good strength, and durability |

More expensive than carbon steel |

Corrosive environments, such as food processing or outdoor equipment |

|

Tool Steel |

High hardness, excellent wear resistance, withstands high temperatures |

More expensive, may require special handling or treatment |

High-load and high-wear applications, such as manufacturing machinery |

|

Ceramic |

Extremely high hardness, excellent wear resistance, high-temperature operation, non-magnetic, corrosion-resistant |

Brittle, more expensive |

High-speed applications, medical devices, environments where magnetic properties are a concern |

|

Composite Materials |

Lightweight, corrosion-resistant, can be tailored for specific properties |

Generally less durable than metal options, can be more expensive |

Applications requiring a balance of weight and performance, such as aerospace or specialized machinery |

|

Plastic |

Lightweight, corrosion-resistant, cost-effective |

Lower strength and wear resistance compared to metals |

Low-load applications where corrosion resistance and weight are more critical than strength |

Design Features

Consider design features that can enhance performance, such as:

- Lubrication Holes: Facilitate easy maintenance and prolong bearing life.

- Seals and Shields: Protect against contaminants and retain lubrication.

- Cage Construction: Ensures the proper alignment of rolling elements and reduces friction.

Practical Selection Process

Assessing Your Needs

Figure Out Load Needs

Start by figuring out how heavy a load your cam follower needs to support. Picking one that matches your load requirements prevents wear and breakdown, saving on replacements.

Check Speed and Movement

Consider how fast and in what way your cam follower will move. For high-speed or continuous motion, choose a design that reduces friction and heat.

Think About the Setting

Where will the cam follower operate? Harsh conditions like extreme temperatures or exposure to chemicals call for durable materials like stainless steel or special coatings.

Comparing Specifications

Match the specifications of the cam follower with your needs. Check their weight handling, speed limits, material fit, and special design traits to ensure they meet your demands.

Consulting with Experts

Ask for help from experts and get technical support from the makers or sellers. They can offer helpful tips and suggest the best options for your particular needs.

Case Studies and Examples

In every scenario described below, cam followers are crucial. This is especially true for those with crowned outer rings, which are made for carrying loads and need to be correctly positioned on the cam's side.

Industrial Machinery Applications

- Automotive Assembly Lines: Cam followers are crucial in car factories for smoothly moving and precisely placing parts for welding and assembly. They keep the production line moving without interruptions.

- Bottling Plant Machinery: Cam followers improve the smoothness and efficiency of conveyor systems in bottling plants. They help manage fast moves and sudden stops during filling, capping, and labeling, reducing downtime and making the whole process flow better.

- Textile Manufacturing Equipment: They keep fabric moving accurately in textile machines, making sure the tension and alignment are just right for top-quality, flawless textiles.

- Printing Presses: In printing press feeders, cam followers are key to keeping paper aligned and high-quality, affecting how fast and accurately the press operates.

- Food Processing Systems: In meat processing, stainless steel cam followers resist rust and are easy to clean, ensuring they meet strict hygiene standards.

- Agricultural Machinery: Cam followers in farm equipment need to be durable to manage changing loads and tough conditions, playing a key role in keeping efficiency high and maintenance low.

Automotive Applications

- Engine Valve Trains: Cam followers in high-performance cars precisely time valves for better engine power and response.

- Fuel Pumps: Cam followers in diesel engines accurately deliver fuel to the engine, crucial for heavy trucks on long trips.

- Transmission Systems: Cam followers in semi-automatic transmissions make gear changes quick and smooth, improving drive control.

- Throttle Control: They change spinning motion to straight motion for finely tuned throttle control in sports cars, boosting engine response.

- Automotive Actuators: In luxury cars, cam followers make sure the power seat adjustments are smooth and precise, enhancing comfort with just a button press.

- Suspension Systems: In off-road SUVs, cam followers play a key role in keeping the suspension in top condition, ensuring a smoother ride by keeping the wheels aligned and balanced.

- Automotive Assembly Robots: Cam followers help robots in car manufacturing do precise welding and fitting of parts, keeping the quality top-notch and production smooth.

Precision Equipment

- CNC Machines: Cam followers ensure cutting tools move accurately along paths, boosting precision.

- Robotic Arms: Cam followers control accurate arm movements for tasks like welding with precision.

- Assembly Lines: Cam followers guide parts precisely into place for seamless assembly.

- Medical Devices: Cam followers are essential for precise movement in devices like surgical robots.

- Chip Manufacturing: They ensure exact wafer positioning during semiconductor production.

- 3D Printing: They control print head or platform movement for accurate prints.

- Optical Systems: They adjust mirrors or lenses in telescopes or lasers with high accuracy.

- Farming Equipment: They guide seeding and harvesting machinery for precise operations.

- Textile Machines: They ensure thread or fabric moves accurately for quality textiles.

- Watchmaking: They control precise movement of watch components for accurate timekeeping.

Some Brands of Cam Followers

In the industry, several brands are well-recognized for their quality and reliability in manufacturing cam followers.

- McGill Cam Followers: McGill is a well-known brand that offers a wide selection of cam followers, including standard, heavy-duty, and flanged types.

- RBC Cam Followers: RBC is known for making top-quality cam followers used for precise linear motion in many applications.

- IKO Cam Followers: IKO, a Japanese company, is renowned for its precision cam followers and various other bearings.

Conclusion

Choosing the right cam follower is vital for the performance and longevity of your mechanical systems. Please take a close look at the important factors we've talked about—like load capacity, speed, environmental conditions, material, and design features—to make sure you get the best performance. Also recommended is to consult a professional supplier. For more information or tailored advice and solutions about bearings for your application, contact us today.

Keep Learning