Kaydon Bearings: Ensuring Precision and Reliability in Aerospace

In the aerospace industry, precision and reliability are paramount. Every component, down to the smallest bearing, plays a critical role.

Kaydon Bearings, a trusted name in the industry, offers a range of bearings designed specifically for aerospace applications. Their products are engineered to withstand the extreme conditions of space, while ensuring optimal performance.

From roller bearings to ultra-slim bearings, Kaydon's offerings cater to a variety of needs. This article delves into the world of Kaydon Bearings, exploring their role in the aerospace industry.

Importance of Bearings in Aerospace

Role of Bearings

Bearings reduce friction, support loads, and allow smooth rotation in aerospace systems. They are essential for aircraft, satellites, and spacecraft.

Aerospace Requirements

Aerospace bearings must meet strict standards:

- High Precision: They need to be made to exact specifications for accurate movement.

- Durability: They should withstand long-term use and resist wear.

- Extreme Conditions: Bearings must work reliably in extreme temperatures, high stress, and vacuum environments.

- Load Capacity: They should handle heavy loads without losing performance.

- Corrosion Resistance: Bearings need to resist corrosion in harsh conditions.

Overview of Kaydon Bearings

Introduction to Kaydon Bearings

Kaydon Bearings are known for their high-quality bearings designed specifically for aerospace applications. They have a strong reputation in the industry for meeting aerospace demands.

Key Features of Kaydon Bearings

Kaydon Bearings are great for aerospace because they offer:

- High Precision

- Durability

- Corrosion Resistance

- Heavy Load Capacity

Common Types of Kaydon Bearings Used in Aerospace

Kaydon Thin Section Bearings

Kaydon thin section bearings, like Reali-Slim Bearings, Ultra Slim bearings, Constant Section (CS) Bearings, offer a compact design and high load capacity, making them ideal for aerospace applications where space and weight are critical.

Kaydon Slewing Ring Bearings

Used in systems requiring rotational support, these bearings offer durability and high performance. These bearings include:

Four Point Contact Ball Slewing Ring Bearings

Reali-Slim TT Turntable Bearings

Eight Point Contact Ball Slewing Ring Bearings

Cross Roller Slewing Ring Bearings

Three-Row Cross Roller Slewing Ring Bearings

Precision Engineering in Kaydon Bearings

Advanced Manufacturing Processes

Kaydon Bearings use advanced methods to ensure high precision and quality. Here's how:

- Modern Technology: Uses the latest machines for accurate bearings.

- Quality Control: Checks every step to maintain high standards.

- Precision Engineering: Ensures bearings meet aerospace needs.

- Continuous Innovation: Invests in research for better solutions.

Quality Control Measures

Strict quality control measures are in place to maintain high standards, ensuring that each bearing meets the required specifications.

Reliability of Kaydon Bearings in Aerospace Applications

Performance in Extreme Conditions

Kaydon Bearings are built to handle tough aerospace environments:

- Temperature Extremes: They work well in very high and very low temperatures.

- High Stress: These bearings support heavy loads without failing.

- Vacuum Environments: They function properly in space where there is no air.

- Radiation Exposure: They resist damage from radiation, crucial for space missions.

Longevity and Maintenance

Kaydon Bearings are durable and long-lasting, so they don't need frequent maintenance. This improves the overall reliability of the system.

Case Studies

Kaydon Bearings are used in aerospace applications, such as:

- Aircraft: Used in flight controls and landing gear for smooth operation.

- Satellites: Provide dependable performance in space.

- Space Exploration Vehicles: Work reliably under extreme conditions.

These show their reliability and performance in tough aerospace environments.

Material and Design Innovations

Corrosion-Resistant Materials

- Stainless Steel: Excellent at resisting moisture, chemicals, and extreme temperatures, making it ideal for harsh environments.

- Nickel Plating: Adds an extra layer of protection against corrosion and wear.

- Endurakote® Coating: Provides high resistance to corrosion, especially in salty conditions.

- Ceramic Materials: Resist oxidation and thermal stress, enhancing bearing longevity.

- Composite Materials: Lightweight and strong, used for specific applications needing high strength and low weight.

Design Innovations

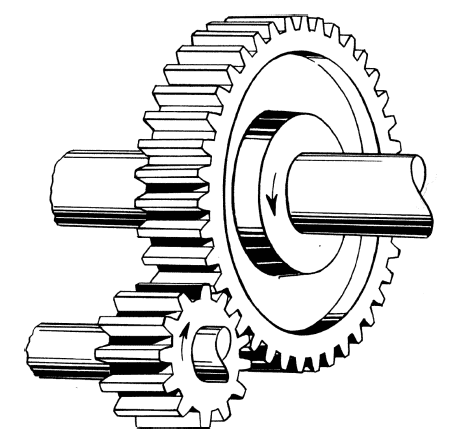

Kaydon Bearings include several design innovations to meet aerospace needs:

- Integrated Gears: Built-in gears reduce the need for extra parts and save space.

- Custom Mounting Holes: Makes installation easier and allows more design flexibility.

- Thin Section Bearings: Save space and weight without losing performance.

- Enhanced Sealing: Protects bearings from contaminants, ensuring they last longer.

- Advanced Materials: Uses strong composites and ceramics for tough conditions.

Load Capacity and Performance

Kaydon Bearings are designed to handle heavy loads while maintaining high precision and reliability.

Here are the key features:

- Strong Construction: Made from durable materials like stainless steel and advanced composites.

- Even Load Distribution: Spread loads evenly, reducing wear and extending lifespan.

- Specialized Solutions: Tailored to meet specific aerospace needs, such as flight controls and landing gear.

- Reliable Under Stress: Perform well under extreme conditions, including high speeds and temperature changes.

- Thorough Testing: Undergo rigorous testing to ensure they meet high load capacity and reliability standards.

Kaydon Bearings reduce friction and wear, which helps extend the life of aerospace components and improves overall system performance.

Applications of Kaydon Bearings in Aerospace

Satellites and Spacecraft

- Works in Space: Designed to function well in the vacuum of space.

- Handles Temperature Changes: Can cope with extreme temperature variations.

- Reliable: Provides smooth performance, reducing the risk of problems.

- Essential for Space Tech: Crucial for satellite systems and other space-bound equipment.

Aircraft Systems and Components

- Flight Controls: Ensure smooth and precise operation of flight controls.

- Landing Gear: Improve the durability and reliability of landing gear.

- Highly Accurate: Necessary for precise movements in aviation.

- Tough and Durable: Can withstand the challenging conditions of flight, enhancing safety.

Launch Vehicles

- Vibration Resistant: Can handle intense vibrations during liftoff and space travel.

- Strong Load Capacity: Can bear heavy loads during launches.

- Tough in Harsh Conditions: Maintain performance in extreme environments.

- Supports Missions: Helps in the successful deployment of payloads into space.

Meeting Industry Standards and Customization Needs

Compliance with Standards

Kaydon Bearings are tested to ensure high quality. They meet ISO 9001 and AS9100 standards. This guarantees their reliability in aerospace applications.

Custom Bearing Solutions

Kaydon offers custom solutions for aerospace needs. Their engineers design bearings for flight controls, landing gear, and space vehicles with clients. This ensures optimal performance and improves system efficiency and reliability.

Conclusion

Kaydon Bearings offer the precision and reliability needed for aerospace applications. They are backed by advanced engineering and strict quality control.

Choosing the right bearings is crucial for the safety and efficiency of aerospace systems.

Consider Kaydon Bearings for your aerospace needs. Contact us for more information or to discuss your specific requirements.

- Previous: Understanding the Load Capacities of Kaydon Bearings

- no more

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(2)

- Tapered Roller Bearings(3)

- Slewing Ring Bearings(5)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(42)

- Low Temperature Bearings(1)

- Ball Bearings(10)

- Bearing Load(5)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(25)

- Aerospace Bearings(2)

- Polyurethane Rollers(3)

- Cam Follower(5)

- Linear Bearings(1)

- Spherical Bearings(1)

- Mounted Bearings(2)

- Kaydon Bearings(3)

- Guide Wheel(1)