Understanding the Load Capacities of Kaydon Bearings

Bearings ensure the smooth operation and long life of mechanical components. Kaydon Bearings are known for their high performance and versatility. This blog explains the load capacities of some common types of Kaydon Bearings, helping you choose the right one for your needs.

Overview of Kaydon Bearings

What are Kaydon Bearings?

Kaydon Bearings are high-quality parts made to handle different loads in many industries. They are used in areas like aerospace and medical devices because they are reliable. Their special designs and materials help them carry heavy loads while working smoothly and efficiently.

Typical Types of Kaydon Bearings

Kaydon offers a range of bearing types to suit different applications:

- Kaydon Slewing Bearings: Designed for heavy-duty applications requiring both radial and axial load support; such as RealiSlim TT Turntable Bearings, Cross Roller Slewing Ring Bearings, Four Point Contact Ball Slewing Ring Bearing, etc.

- Kaydon Thin Section Bearings: Known for their slim profiles and ability to handle large loads relative to their size; such as Constant Section (CS) Bearings and Kaydon Reali-Slim Bearings, etc.

Kaydon Reali-Slim Bearings: Optimized for applications requiring space-saving solutions without compromising on load capacity.

Understanding Load Capacities

Load Capacity Fundamentals

The load capacity of a bearing is the maximum load it can support without affecting its performance or lifespan. Factors that influence load capacity include the bearing's material, design, and manufacturing precision. Knowing these basics helps you choose the right bearing for your specific needs.

Load Ratings and L10 Life

When selecting a bearing, understanding the load ratings and the L10 life is crucial. Load ratings indicate the maximum load that a bearing can carry. The L10 life is a statistical measure of the expected life of the bearing under a given set of loads. Kaydon provides these specifications to ensure optimal performance and longevity.

Types of Loads

Bearings are subjected to different types of loads, each affecting their performance differently:

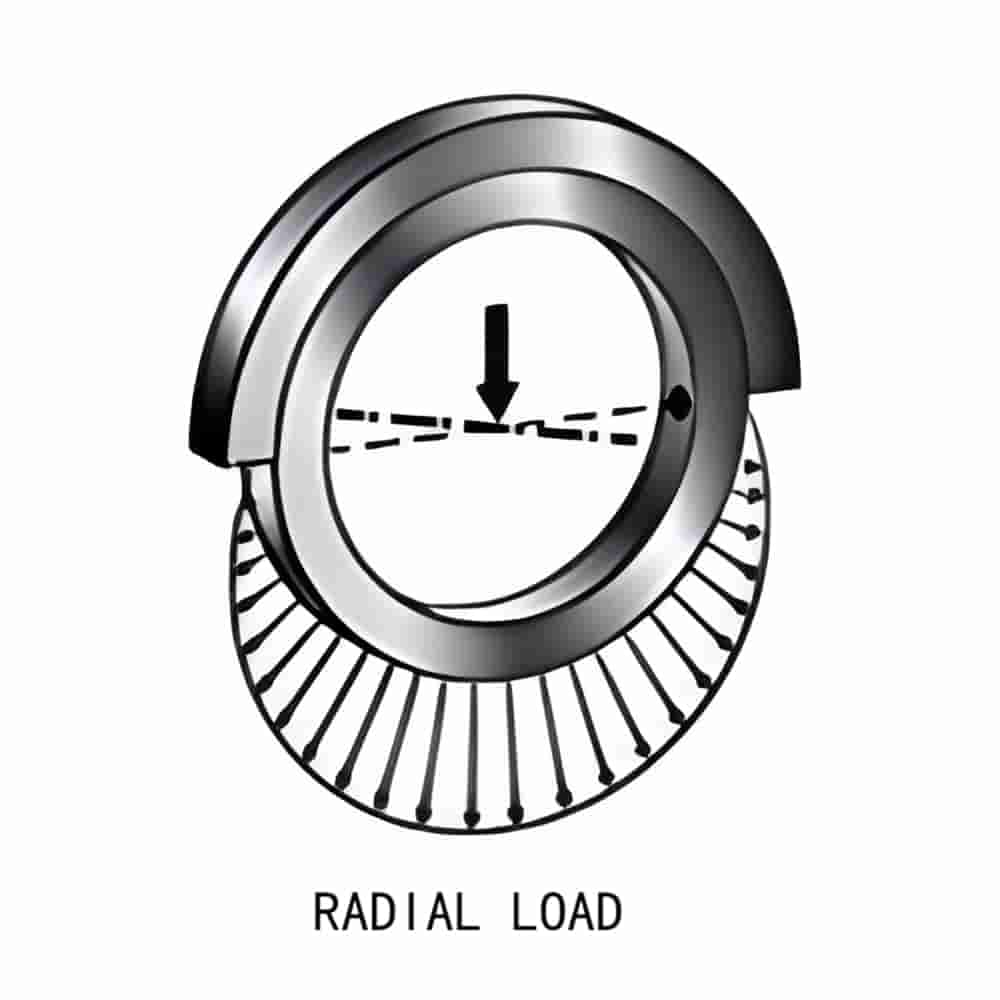

- Radial Load: Acts perpendicular to the shaft and is common for deep groove ball bearings.

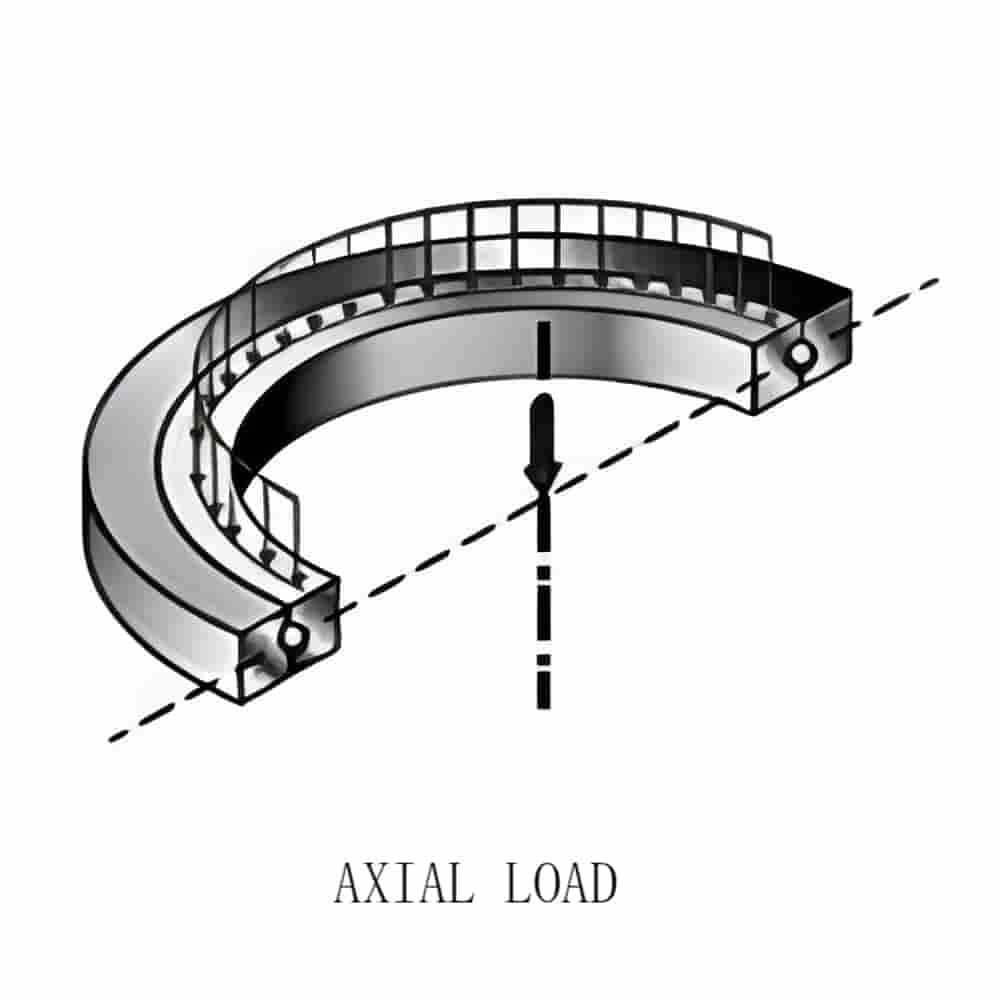

- Axial Load: Acts parallel to the shaft and is crucial for applications involving axial and moment loading.

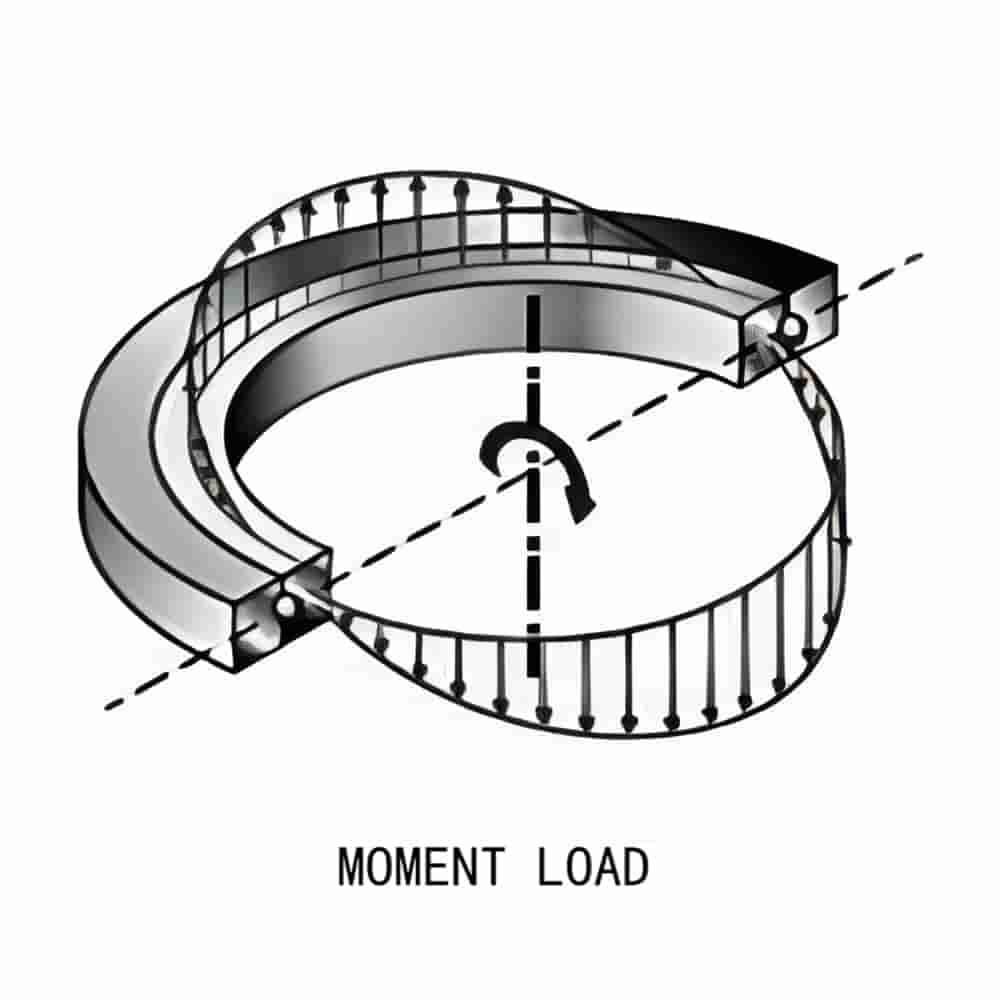

- Moment Load: This combines radial and axial loads, often used when precise positioning and rotation are needed.

Load Capacities of Different Kaydon Bearings

Kaydon Slewing Bearings

Kaydon slewing bearings, also known as slewing rings, are designed to handle large axial, radial, and moment loads. These bearings are often used in heavy machinery like cranes and excavators. They provide stability and support for rotational movement.Their high load ratings make them suitable for demanding applications, including wind turbines and radar systems.

Kaydon Thin Section Bearings

Kaydon thin section bearings are characterized by their ability to handle high loads relative to their thin cross-sections. These bearings are ideal for applications where space constraints are a concern, such as in robotics and medical devices. Despite their slim profiles, they provide excellent load capacities and contribute to the extended life of the bearing.

Load Analysis for Kaydon Thin Section Bearings

Modern load analysis uses advanced software to apply actual loads to Kaydon bearings and determine the resultant load on each ball. This process calculates the static safety factor and dynamic L10 life, ensuring accurate life predictions.

Considerations for Radial Loading:

- Larger clearances result in fewer balls carrying the load, reducing dynamic life.

- Larger preloads may overload the bearing before the loads are applied.

Considerations for Axial and Moment Loading:

- Larger clearances permit higher contact angles, better supporting applied loads.

- Excessive preload can lead to overloading before loads are applied.

To calculate the static safety factor or dynamic life of a bearing, a computer analyzes individual ball loads. The ball with the highest load sets the maximum stress level for the static safety factor. A weighted analysis of all ball loads determines the dynamic L10 life.

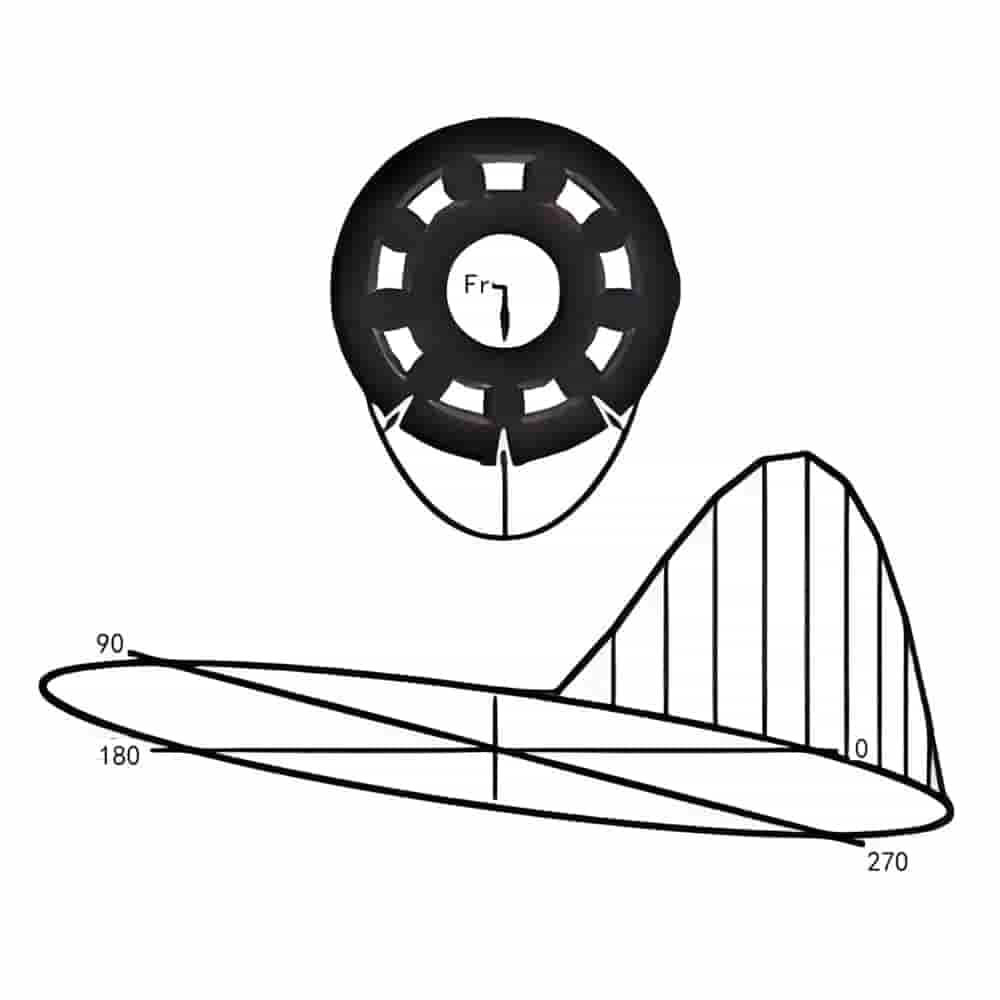

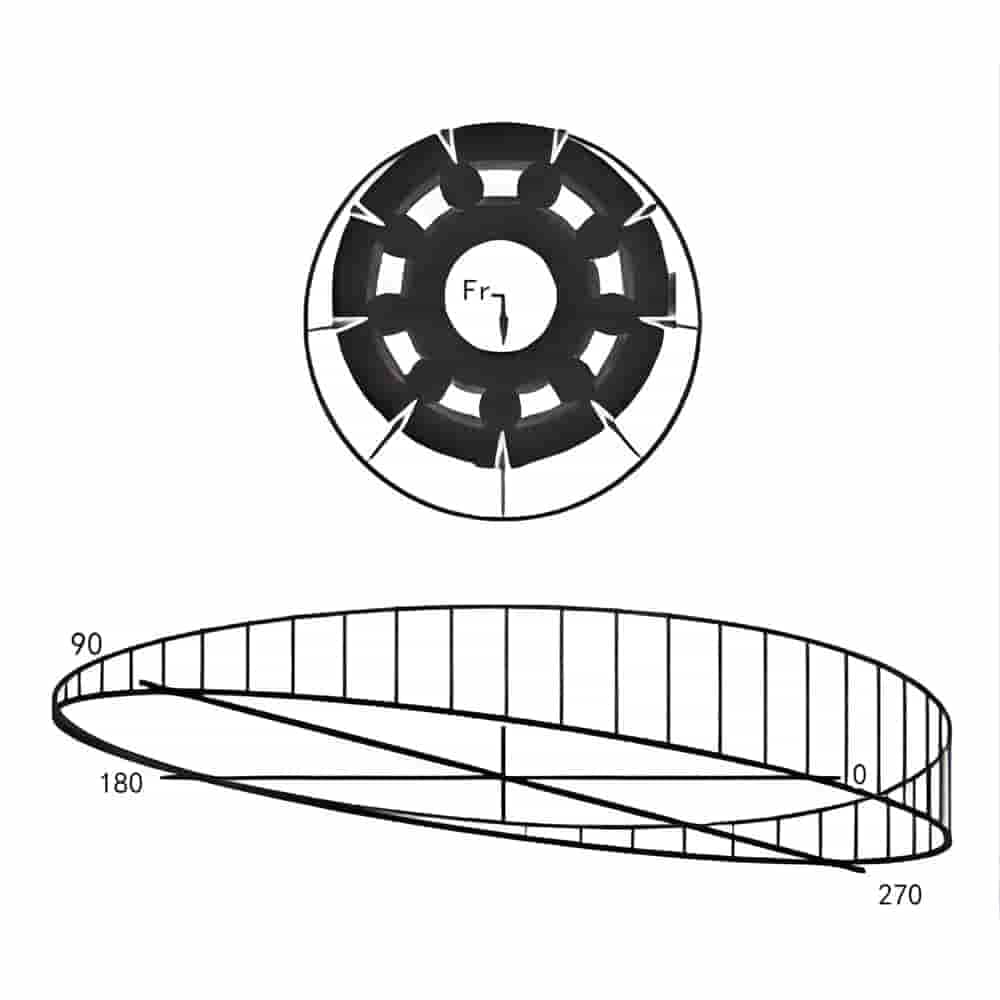

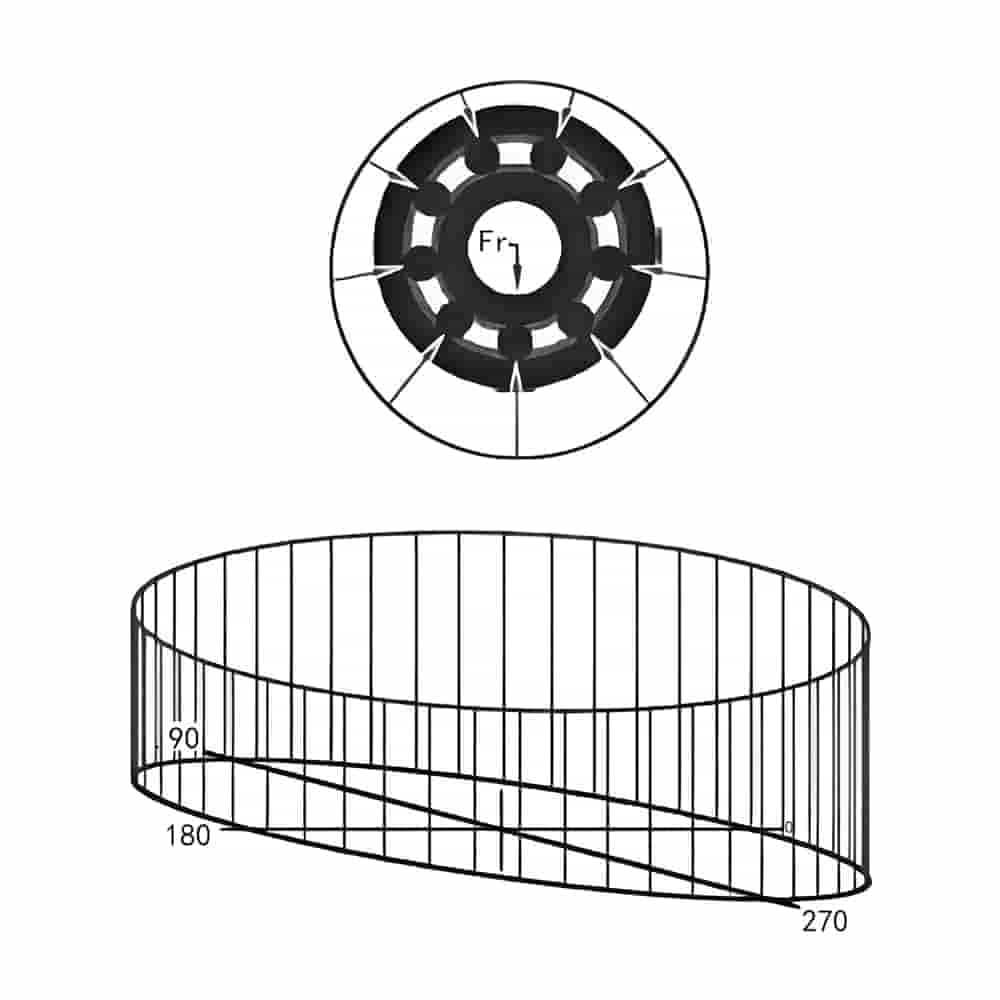

Graphs below illustrate ball load distribution for three common bearing types, showing load magnitudes where higher peaks indicate greater loads.

KA040CP0 with a 100 lbs. radial load, bearing clearance, causing few balls to support the load.

In this configuration, only three balls carry the load, with the bottom ball experiencing the highest load.

KA040CP0K with a 100 lbs. radial load, a light preload, ensuring all balls carry the load.

This Kaydon radial bearing's light preload distributes the load across all balls, with the bottom middle ball bearing less load than in the previous example.

KA040CP0P with a 100 lbs. radial load, a heavy preload.

This radial contact bearing's heavy preload ensures all balls are loaded, with the bottom ball carrying a load as high as in the initial clearance example.

Kaydon Reali Slim Bearings

Reali Slim bearings are made for applications that need compact solutions without losing performance. They can handle large radial and axial loads, making them ideal for aerospace and defense. Their precise engineering ensures they perform well while staying slim.

Application-Specific Capacity Analysis

Engineers must consider all types of loads, including static loads for stationary parts and dynamic loads for moving parts. Kaydon offers a variety of bearings to handle different loads. Reali-Slim® bearings are suitable for light to moderate loads. For large axial, radial, and moment loads, heavy-duty slewing rings are available.

Comparing Load Capacities

Comparative Analysis

When comparing the load capacities of Kaydon bearings, consider your specific needs. Slewing bearings and rings are great for heavy-duty uses with high axial and radial loads. Thin section and Reali Slim bearings are better for compact, lightweight applications.

Application-Based Recommendations

Selecting the right bearing involves understanding the specific load requirements of your application. For heavy machinery, slewing bearings and rings are recommended due to their high load ratings. For applications with space constraints, thin section and Reali Slim bearings are ideal.

Practical Considerations

Installation and Maintenance Impact

Proper installation and maintenance are crucial for the load capacity and lifespan of bearings. Correct alignment, lubrication, and handling prevent premature wear and maximize bearing performance. Regular maintenance checks keep the bearings working well and extend their L10 life.

Real-World Examples

Consider Kaydon slewing rings used in wind turbines. They can handle large axial and moment loads, ensuring reliable operation even in strong winds. On the other hand, thin section bearings in robotic arms offer precision and durability despite their small size. This shows the versatility and capability of Kaydon Bearings in different real-world applications.

Conclusion

Understanding the load capacities of Kaydon Bearings is crucial for selecting the right bearing type for your applications. Kaydon has a bearing solution for both heavy machinery and compact devices. For more help, talk to experts to choose the best bearing for efficiency and long life in your projects.

Keep Learning