What Are the Three Main Types of Mounted Bearings?

Mounted bearings are vital for keeping industrial machines running smoothly. They support rotating shafts, align them properly, reduce friction, and help transfer power. In this blog, we explain the three main types of mounted bearings. Knowing about these types and their uses will help you choose the right one for your needs.

Understanding Mounted Bearings

Mounted bearings, also known as mounted bearing units, are a type of rolling-element bearing. They are encased in a housing that can be bolted onto a machine. This design simplifies the installation process and enhances the bearing's performance.

Mounted bearings are designed to handle both radial and axial loads. They support the rotating shaft and keep it parallel to the mounting surface. By reducing friction, they allow the shaft to rotate smoothly, improving the efficiency of the machinery. Understanding the different types of mounted bearings is crucial for selecting the right one for your application.

Mounted bearings play a vital role in various types of machinery. They are commonly found in industrial equipment, conveyors, electric motors, and agricultural machinery. Their primary function is to provide support to the rotating shaft, allowing it to spin freely with minimal friction.

By reducing friction, mounted bearings help to increase the efficiency of the machinery. They also help to extend the lifespan of the machine by preventing premature wear and tear. Therefore, selecting the right types of mounted bearings is crucial for the optimal performance and longevity of the machinery.

Pillow Block Bearings: Versatile and Common

Definition and Structure

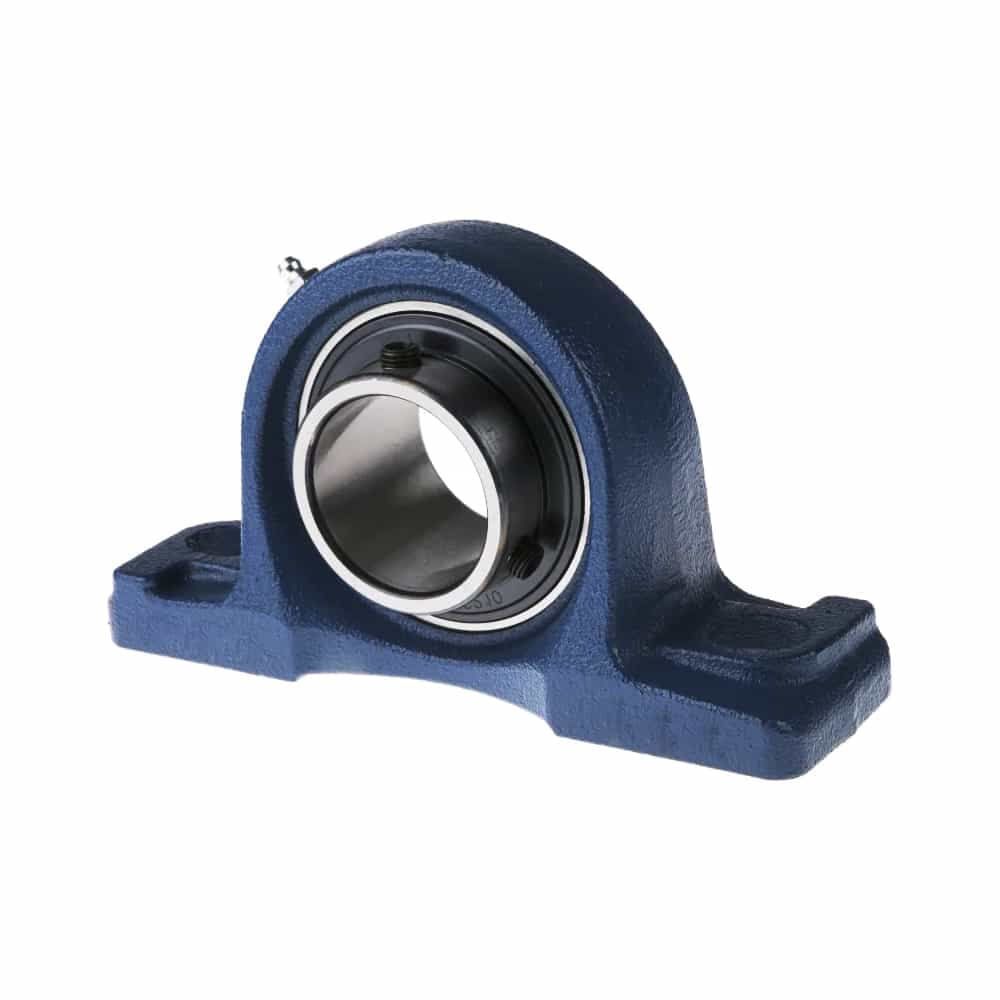

Pillow block bearings, also known as plummer block bearings, are among the most common types of mounted bearings. Named for their resemblance to a pillow, these bearings feature a block-shaped housing that supports a rotating shaft. The mounting base plane is perpendicular to the shaft, with bolt holes parallel to the shaft. Each unit includes a housing, typically made of cast iron, pressed steel, or aluminum, providing robust support and high load-bearing capacity. Inside the housing is an insert bearing, which is usually self-aligning and can be a ball or roller type depending on the load and speed requirements.

Applications

Pillow block bearings are widely used across various industries due to their versatility and durability. Common applications include:

- Construction

- Timber

- Aggregate

- Mining

- Cement industries

- Conveyor systems

- Agricultural machinery

- HVAC equipment

Their ability to be mounted on vertical, horizontal, and inclined surfaces makes them suitable for a range of installation environments. They are ideal for large-scale, stationary manufacturing, and processing applications.

Variants

Pillow block bearings are available in solid or split housing designs. Split housing allows for easy dismantling and bearing replacement, which is beneficial for maintenance. Variants include:

- Standard-duty types: With two mounting holes.

- Heavy-duty types: With four mounting holes, providing additional stability and support for more demanding applications.

Installation and Maintenance

Installing a pillow block bearing involves securing the housing to the mounting surface using bolts through the mounting holes. The shaft is then inserted into the bearing and secured with a locking mechanism, ensuring the shaft is aligned correctly to prevent uneven wear and premature bearing failure.

Regular maintenance is essential to extend the lifespan of pillow block bearings. This includes:

- Regular lubrication to reduce friction and heat.

- Monitoring for signs of wear or damage, such as excessive noise or vibration.

- Regular inspection and maintenance to prevent unexpected machinery downtime.

Flange Block Bearings: When Shaft Axis Is Perpendicular

Definition and Structure

Flange block bearings, also known as flange mounted bearings, feature a flanged housing with a ball or roller bearing insert. These mounted bearings support shafts running perpendicular to the mounting surface, making them ideal for applications where the shaft needs to be supported at a right angle to the mounting surface. Available in various shapes such as square, round, and oval, they come in two-bolt, three-bolt, and four-bolt configurations, each providing different levels of load support and stability.

Applications

Flange block bearings are commonly used in light-duty industrial applications due to their versatility and reliability. Typical applications include:

- Conveyors

- Material handling systems

- HVAC equipment

- Light-duty food processing machinery

- Textile machines

- Baggage handling systems

Their design ensures smooth and efficient operation by providing reliable support and alignment for shafts.

Variants

- Two-bolt flange bearings: Compact and suitable for supporting medium loads.

- Three-bolt flange bearings: Offer a sturdier mount and better load distribution.

- Four-bolt flange bearings: Provide maximum strength and support for more demanding applications.

- Additional variants: Piloted flanged cartridges and cylindrical cartridges are available for improved mounting and support in specific applications.

Characteristics and Differences

Flange mounted bearings are versatile and can support both radial and axial loads, making them a flexible choice for many applications. They differ from pillow block bearings primarily in their mounting orientation. While pillow block bearings support a shaft running parallel to the mounting surface, flange mounted bearings support a shaft running perpendicular to the mounting surface.

Materials and Durability

Flange block bearings are typically made from durable materials like cast iron or steel, providing strength and resistance to corrosion and wear. Proper maintenance, including regular lubrication and inspection, is crucial to extend the lifespan of these bearings. Correct installation is also essential to prevent premature bearing failure.

Hanger Bearings

Definition and Structure

Hanger bearings are specifically designed for use in industrial screw-conveyor assemblies and similar equipment. They feature a split roller bearing housed in a unit that can be suspended from conveyors. This split housing design makes maintenance and replacement easy, helping to minimize downtime.

Applications

Hanger bearings are commonly used in:

- Automotive drive shaft assemblies

- Aircraft drive shaft assemblies

- Marine drive shaft assemblies

Screw conveyors handling abrasive bulk materials such as grains and wood fibers

These mounted bearings are designed to accommodate airframe deflections and assembly variations, which helps to reduce unequal operating angles between universal joints, thereby minimizing vibration and stress.

Features and Benefits

Hanger bearings need regular lubrication to work well and last long. They come in different materials like wood, bronze, ceramics, cast iron, steel, urethane, and plastics. This variety makes them useful in many industrial settings.

Key Considerations for Selecting Mounted Bearings

Load Capacity

Choose bearings that can handle the weights and forces they will face. They must support both radial and axial loads without breaking or deforming.

Speed Requirements

Make sure the mounted bearings match the speed of your machinery. High-speed machines need bearings that can reduce friction and heat.

Operating Environment

Consider the environment where the mounted bearings will be used. Bearings in extreme temperatures, humidity, or with contaminants need strong seals and materials that resist corrosion.

Maintenance and Durability

Look for mounted bearings that are easy to maintain and durable. Features like split housing and protective covers make them easier to inspect, replace, and last longer.

Conclusion

Understanding the three main types of mounted bearings can help you select the right bearing for your application. Each type offers unique design features and benefits suited to different industrial needs.

When choosing mounted bearings, consider load capacity, speed, environment, and maintenance to ensure optimal performance. For expert help, contact a trusted supplier like LILY Bearing. In addition to standard mounted bearings, we also offer Corrosion Protection Bearing Units and Corrosion Protection Bearing Inserts. Our team can assist you in finding the best solutions for your needs.

Keep Learning