What Is the Purpose of Flange Mounted Bearings?

Mounted bearings are essential for industrial machines. They support and stabilize rotating shafts, ensuring they stay aligned and reduce friction. This helps machines run smoothly and efficiently. Flange mounted bearings are especially useful due to their unique design and versatile uses.

What Are Flange Mounted Bearings?

Flange mounted bearings, also known as flange mount bearings, are a type of mounted bearing that features a flanged housing with a preassembled sealed bearing.

This design allows the bearing to be securely mounted perpendicular to the shaft axis, providing robust support and alignment.

The flange can have two, three, or four mounting holes, depending on the specific style, making these bearings adaptable for various installation requirements.

Types of Flange Mounted Bearings

Based on Housing Style

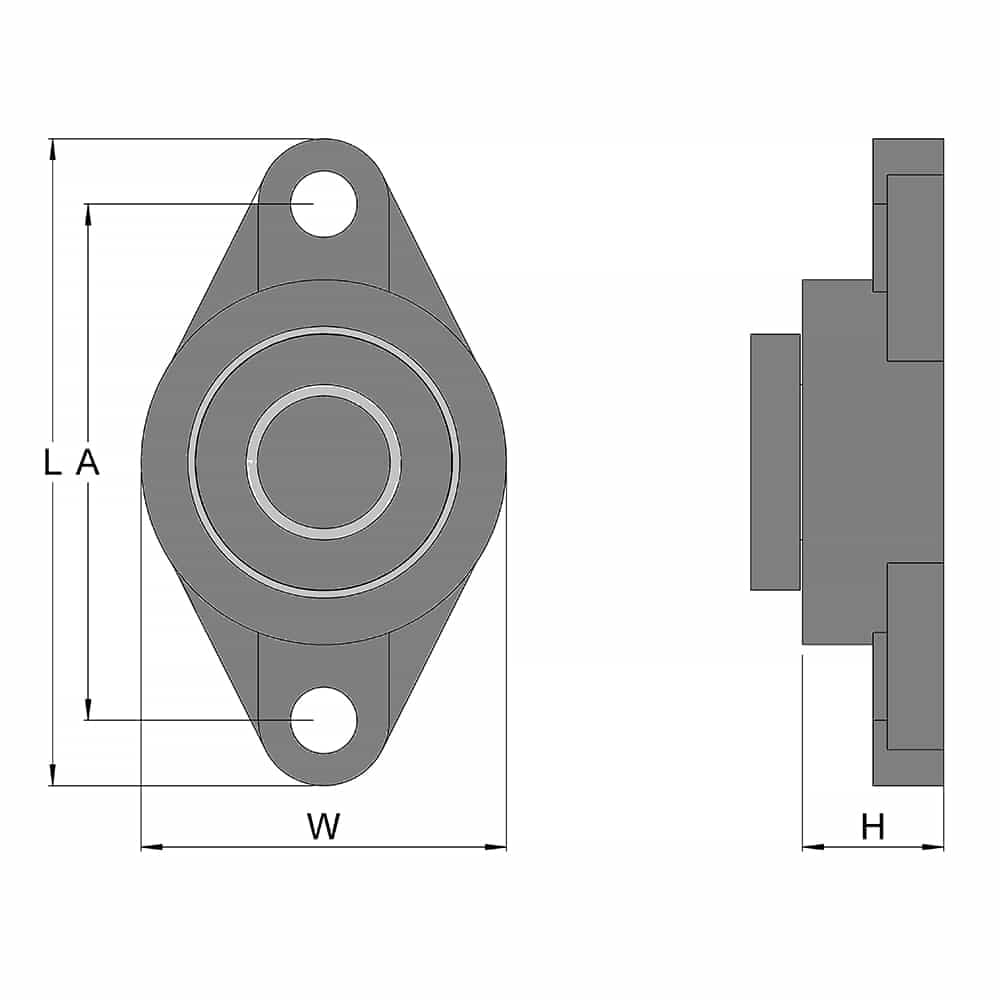

Two-Bolt Flange Mounted Bearings

These bearings are diamond-shaped with two mounting holes, one on each side of the bearing. The mounting holes form a straight line through the axis of the bearing, providing a compact design suitable for medium load applications.

Three-Bolt Flange Mounted Bearings

These bearings have three mounting holes arranged either radially around the bearing axis at 120 degrees or on a triangular flange offset from the bearing axis. This design offers a sturdier mount and better load distribution.

Four-Bolt Flange Mounted Bearings

These bearings have four mounting holes arranged around the bearing axis and usually come in round or square housings. They offer maximum strength and support, making them perfect for heavy-duty applications.

Based on Rolling Elements

Bearings used in flange mount housings are known as insert bearings. Various types of bearings can be used in these housings, depending on the application and operating needs.

Ball Bearings

- Use balls as the rolling element.

- Provide smooth, low-friction motion in rotary applications.

- Consist of an inner and outer ring, balls, and usually a cage or ball separator.

Roller Bearings

- Use rollers as the rolling element.

- Offer smooth, low-friction motion in rotary applications with higher radial load capacities than ball bearings.

- Consist of an inner and outer ring, rollers, and usually a cage or roller separator.

Types of Roller Bearings

- Cylindrical Roller Bearings: High radial load capacity and moderate thrust loads.

- Spherical Roller Bearings: Common in flange mounted bearings; have two rows of barrel-shaped rollers between an outer ring with a spherical raceway and an inner ring with two inclined raceways.

- Tapered Roller Bearings: Contain tapered inner and outer rings and rollers, resembling a cone segment; can handle heavy axial and radial loads.

- Needle Roller Bearings: Similar to cylindrical roller bearings but with a smaller diameter-to-length ratio; designed for radial load applications where a low profile is needed.

Plain Bearings and Sleeve Bearings:

- Also known as bushings or journal bearings.

- Used to constrain, guide, or reduce friction in rotary or linear applications.

- Operate through sliding action rather than rolling, requiring lubrication to prevent overheating from friction.

Applications of Flange Mounted Bearings

Flange mounted bearings are used in many industries because they are versatile and reliable. They are particularly beneficial in applications where the bearing must be mounted on a flat surface or at the end of a shaft.

Common uses include:

- Conveyors

- Material Handling

- HVAC Systems

- Food Processing

- Textile Machines

- Baggage Systems

- Agricultural Machinery

Materials and Durability

Housing Materials

The housing of flange mounted bearings can be made from different materials, each best for certain uses:

- Cast Iron: Strong and durable, great for heavy-duty work.

- Pressed Steel: Low carbon steel that's pressed, making it affordable.

- Plastic: Materials like acetal, nylon, and PTFE. They resist chemicals, reduce friction, and are good for clean areas.

- Stainless Steel: Resists chemicals and corrosion, perfect for high-pressure uses.

Key Purposes of Flange Mounted Bearings

Load-Bearing Capacity

- Supports Heavy Loads: Flange mounted bearings are designed to handle heavy loads, which prevents the shaft from bending.

- Prevents Damage: By reducing deflection, these bearings help prevent vibration and potential damage to machinery.

- Maintains Integrity: This effective load distribution keeps equipment strong and durable, ensuring it lasts longer.

Stability and Alignment

- Accurate Alignment: Flange mounted bearings ensure that rotating shafts stay properly aligned, reducing wear and tear on parts.

- Minimizes Friction: Accurate alignment also minimizes energy loss due to friction, helping machines run more efficiently.

- Prevents Issues: Proper alignment prevents problems like uneven load distribution and increased friction, especially important in high-speed applications.

Ease of Maintenance and Replacement

- Quick Maintenance: The flanged housing design allows the bearing to be unbolted and removed quickly, making maintenance simpler.

- Reduces Downtime: This easy removal and replacement process helps minimize downtime and maintenance costs, crucial for industries where continuous operation is essential.

- Simplifies Tasks: Regular tasks like inspection, cleaning, and lubrication are faster and easier with flange mounted bearings.

Versatility in Applications

- Wide Use: Flange mounted bearings are used in many types of machinery, including conveyors, material handling equipment, HVAC systems, food processing machinery, textile machines, and baggage handling systems.

- Multiple Options: These bearings come in different styles and materials to fit various needs. They are available in two-bolt, three-bolt, and four-bolt configurations, and made from materials like cast iron, pressed steel, plastic, and stainless steel.

- Adaptable: This variety makes flange mounted bearings adaptable to different operating conditions and environments.

Vibration and Noise Reduction

- Less Vibration: By keeping shafts aligned, flange mounted bearings help reduce vibration and noise in machinery.

- Prevents Wear: Reducing vibration and noise also prevents wear and extends the life of the machinery.

- Improves Performance: This ensures that machines run smoothly and efficiently, reducing the need for frequent repairs.

Key Considerations for Selecting Flange Mounted Bearings

Load Capacity

Understanding both static and dynamic load requirements is crucial when selecting flange mounted bearings. These bearings must handle radial and axial loads effectively to prevent deformation or premature failure. Evaluating the load capacity ensures that the bearings can support the operational stresses of the application.

Dimensions

When selecting a bearing, it's important to consider its size:

- Shaft Size: This indicates the maximum diameter of the shaft or the bore diameter of the bearing. Choosing the correct shaft size ensures a proper fit and reliable operation.

- Height Above Mounting Surface: This measurement is crucial for applications with low clearance. It specifies how much the bearing extends above the mounting surface, affecting the available space and installation options.

Speed Requirements

The operational speed of the machinery is another critical factor in bearing selection. Bearings must be compatible with the machinery's speed to maintain performance and longevity. High-speed applications may require specific types of bearings designed to reduce friction and heat generation.

Operating Environment

The operating environment significantly impacts the design and material selection for flange mounted bearings. Bearings exposed to harsh conditions, such as extreme temperatures, humidity, or contaminants, need materials with strong sealing and corrosion resistance to prevent premature failure.

Maintenance and Durability

Ease of maintenance and durability are important considerations. Bearings designed for easy inspection and replacement help reduce downtime and maintenance costs. Features like split housing and protective covers enhance the bearing's durability and extend its service life.

Versatility in Mounting

With various flange configurations available, such as two-bolt, three-bolt, and four-bolt designs, these bearings offer flexibility in mounting. The mounting holes in the flanges allow for easy installation and provide a secure attachment that can withstand the forces generated during operation.

Conclusion

Flange mounted bearings are vital for industrial machines. They support and stabilize rotating shafts, keep them aligned, and reduce friction. This helps machines run smoothly. LILY Bearing offers various types, including mounted bearing units, mounted bearing inserts, corrosion protection bearing units, and corrosion protection bearing inserts, providing reliable solutions for many applications.

Keep Learning